Are you gearing up for a career in Papier Mache Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Papier Mache Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

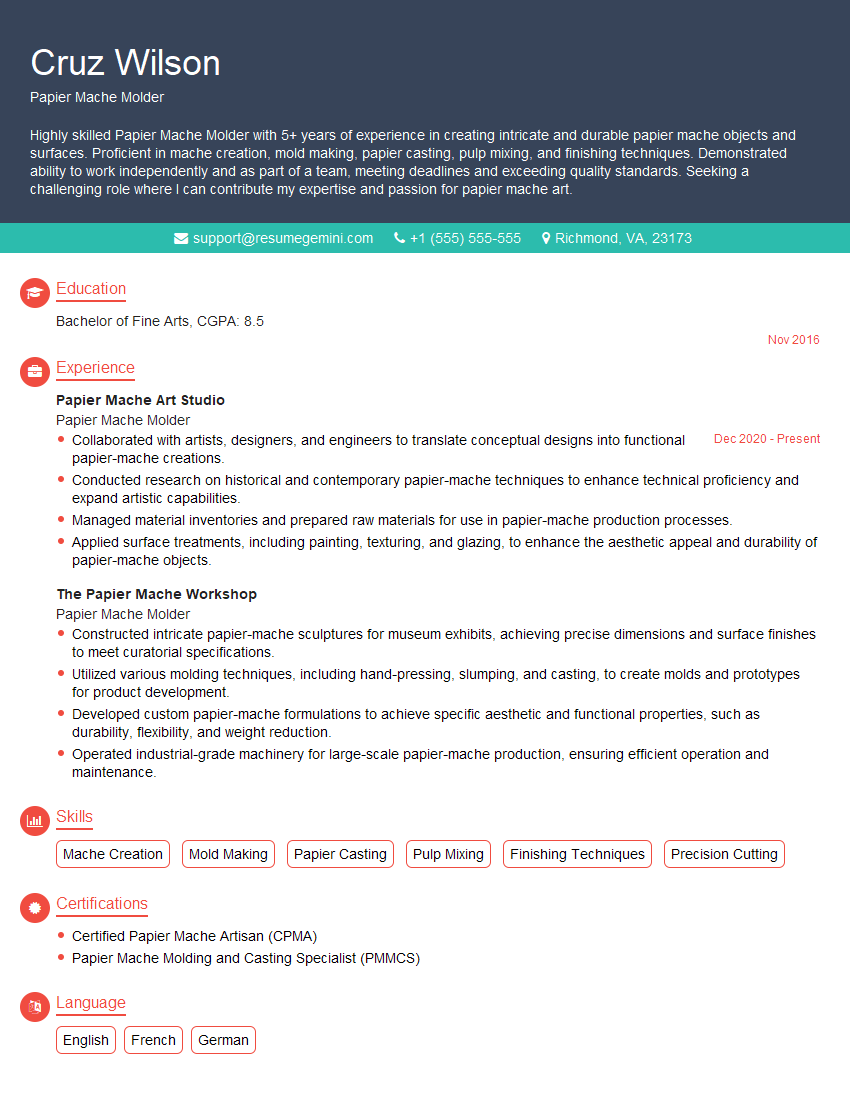

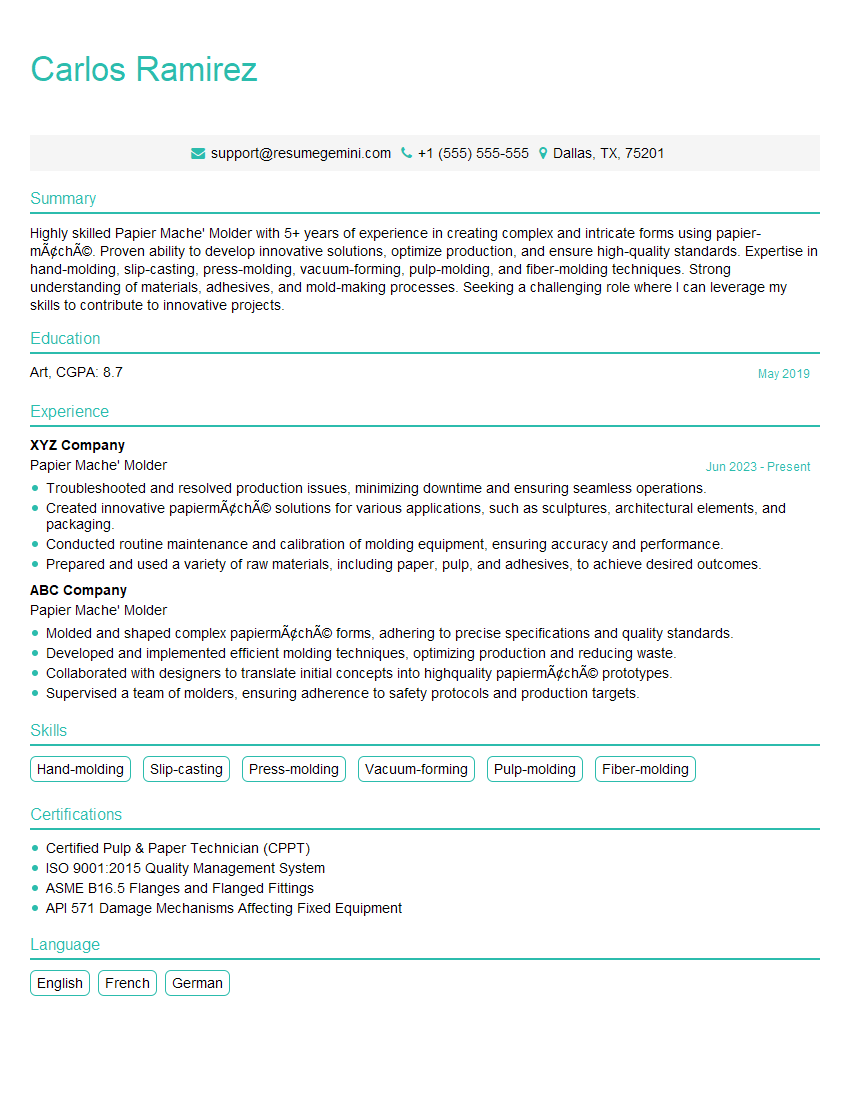

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Papier Mache Molder

1. Describe the process of creating a papier mache mold.

The process of creating a papier mache mold involves several steps:

- Creating a model: Start with a 3D model of the desired shape.

- Applying a release agent: Coat the model with a release agent to prevent the papier mache from sticking.

- Layering papier mache: Dip strips of paper or fabric into a mixture of water and adhesive and apply them to the model, creating multiple layers.

- Drying and hardening: Allow the papier mache to dry and harden completely.

- Removing the mold: Once hardened, carefully remove the mold from the model.

2. What types of materials can be used to create papier mache?

Papier mache can be created using various materials:

- Paper: Newspapers, magazines, or any type of waste paper can be used.

- Fabric: Cotton, muslin, or even old clothes can be utilized.

- Cellulose fibers: Pulp made from wood or other plant fibers can be used for a more durable result.

3. What are the different types of adhesive used in papier mache?

- Wheatpaste: A traditional and inexpensive adhesive made from flour and water.

- White glue: A synthetic adhesive that provides stronger bonds.

- Mod Podge: A commercial adhesive that is easy to use and non-toxic.

- Gum arabic: A natural adhesive derived from the sap of the acacia tree.

4. How do you ensure the strength of a papier mache mold?

To ensure the strength of a papier mache mold:

- Use multiple layers: Apply several layers of papier mache to the mold.

- Allow proper drying: Give the mold ample time to dry and harden thoroughly.

- Add reinforcements: If necessary, use additional materials such as wire mesh or fiberglass to reinforce the mold.

5. What techniques can be used to create intricate details in a papier mache mold?

Shaping the pulp

- Using a mold: Press the papier mache pulp into a pre-made mold to create specific shapes.

- Carving: Once dried, use carving tools to shape and refine the details of the mold.

Adding details to the surface

- Applying additional layers: Layer papier mache pulp to build up details and textures.

- Using stamps: Use rubber stamps or other tools to imprint designs and patterns onto the surface.

6. How do you store and maintain papier mache molds?

To store and maintain papier mache molds:

- Keep them dry: Store the molds in a dry environment to prevent moisture damage.

- Avoid extreme temperatures: Store the molds away from heat or cold to prevent warping or cracking.

- Clean gently: If the molds become dusty, use a soft brush or cloth to clean them gently.

- Repair any damage: If the molds sustain any damage, repair them promptly using papier mache pulp or other suitable materials.

7. What are the common problems that can occur when making a papier mache mold and how do you troubleshoot them?

- Mold is weak: Use more layers of papier mache or add reinforcements.

- Mold is too thick: Use fewer layers of papier mache or thin the pulp.

- Mold is cracking: Allow more time for drying or add a layer of varnish.

- Mold is not releasing from the model: Check the release agent and ensure it is applied evenly.

8. Describe the different uses of papier mache molds.

- Creating sculptures: Casting sculptures and figurines.

- Making masks: Creating decorative or functional masks.

- Producing bowls and dishes: Molding bowls, plates, and other tableware.

- Architectural elements: Creating decorative moldings, friezes, and other architectural features.

9. What are the safety precautions that should be taken when working with papier mache?

- Wear protective gear: Use gloves and a mask when handling wet papier mache.

- Ventilate the workspace: Ensure good ventilation to avoid inhaling harmful fumes.

- Dispose of materials properly: Discard used papier mache and adhesive according to local regulations.

10. What is the difference between a positive and negative mold?

Positive mold

- Captures the outer form of the object.

- Used to cast hollow objects.

Negative mold

- Captures the inner form of the object.

- Used to cast solid objects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Papier Mache Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Papier Mache Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Papier Mache Molders are responsible for creating papier mache products, such as bowls, vases, and sculptures. They use a variety of materials, including paper, glue, and water, to create their products. Papier Mache Molders must have a strong understanding of the papier mache process and be able to create products that are both beautiful and durable.

1. Prepare materials

Papier Mache Molders must prepare the materials they need to create their products. This includes cutting paper into strips, mixing glue with water, and preparing the molds that will be used to shape the papier mache.

- Cut paper into strips

- Mix glue with water

- Prepare molds

2. Apply papier mache to molds

Papier Mache Molders apply papier mache to molds to create the desired shape. They use a variety of techniques to apply the papier mache, including dipping, brushing, and spreading. Papier Mache Molders must be careful to apply the papier mache evenly and to avoid creating any air bubbles.

- Dip paper strips in glue mixture

- Brush or spread papier mache onto molds

- Smooth out papier mache to remove air bubbles

3. Dry and shape papier mache

Papier Mache Molders dry and shape the papier mache after it has been applied to the molds. They use a variety of techniques to dry the papier mache, including air drying, oven drying, and heat gun drying. Papier Mache Molders must be careful to dry the papier mache completely to avoid mold and mildew.

- Air dry papier mache

- Oven dry papier mache

- Heat gun dry papier mache

- Shape papier mache while drying

4. Remove papier mache from molds

Papier Mache Molders remove the papier mache from the molds after it has dried. They use a variety of techniques to remove the papier mache, including peeling, cutting, and sanding. Papier Mache Molders must be careful to remove the papier mache without damaging it.

- Peel papier mache from molds

- Cut papier mache from molds

- Sand papier mache to smooth edges

5. Finish papier mache products

Papier Mache Molders finish the papier mache products after they have been removed from the molds. They use a variety of techniques to finish the products, including painting, staining, and varnishing. Papier Mache Molders must be creative and have a good eye for detail when finishing their products.

- Paint papier mache products

- Stain papier mache products

- Varnish papier mache products

- Add embellishments to papier mache products

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Papier Mache Molder position:

1. Research the company and the position

Before you go on an interview, it is important to do your research. This includes learning about the company’s history, mission, and values. You should also learn about the specific position you are applying for and the responsibilities that come with it. This will help you to answer questions intelligently and show the interviewer that you are genuinely interested in the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work for the company (if possible)

2. Prepare your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and clearly.

- Practice answering common interview questions

- Tailor your answers to the specific job you are applying for

- Be concise and clear in your answers

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also arrive on time for your interview. Being late will show the interviewer that you are not serious about the job.

- Choose appropriate clothing for the interview

- Make sure your clothes are clean and pressed

- Arrive on time for your interview

4. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be yourself and let your personality shine through. Confidence is also important, so make sure to speak clearly and make eye contact with the interviewer. This will show the interviewer that you are confident in your abilities and that you are interested in the job.

- Don’t try to be someone you’re not

- Speak clearly and make eye contact with the interviewer

- Be confident in your abilities

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This can be done by sending a thank-you note or email. In your thank-you note, you should reiterate your interest in the job and thank the interviewer for their time. You can also use your thank-you note to highlight any of your skills or experience that you feel would be particularly valuable to the company.

- Send a thank-you note or email to the interviewer

- Reiterate your interest in the job

- Highlight your skills and experience

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Papier Mache Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.