Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Paraffin Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Paraffin Machine Operator so you can tailor your answers to impress potential employers.

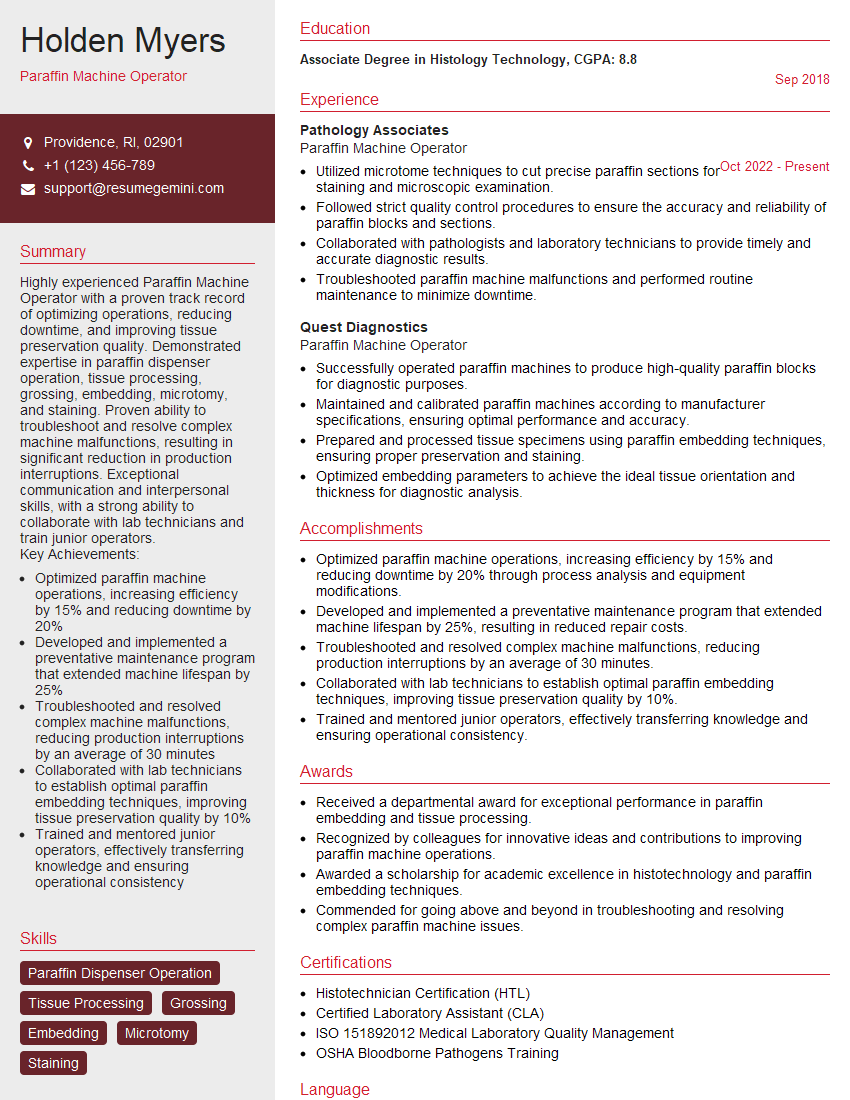

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paraffin Machine Operator

1. What are the different types of Paraffin Machine and explain their usage?

There are two main types of Paraffin Machine:

- Batch Paraffin Machine: This type of machine is used to produce large quantities of paraffin wax in a single batch. It consists of a large tank that is filled with molten wax and a conveyor belt that transports the wax through the machine. The wax is then cooled and solidified as it passes through the machine.

- Continuous Paraffin Machine: This type of machine is used to produce a continuous stream of paraffin wax. It consists of a series of rollers that are coated with a thin layer of molten wax. The wax is then cooled and solidified as it passes through the rollers.

2. What are the key components of a Paraffin Machine and their functions?

Paraffin Tank

- Holds the molten paraffin wax.

- Heated to maintain the wax in a liquid state.

Conveyor Belt

- Transports the wax through the machine.

- May be perforated to allow excess wax to drain.

Cooling System

- Cools the wax as it passes through the machine.

- Can consist of water jets, air jets, or refrigeration units.

Rollers

- Coat the wax with a thin layer.

- Continuously rotate to produce a continuous stream of wax.

3. How do you maintain and troubleshoot a Paraffin Machine?

Paraffin Machine maintenance includes:

- Regular cleaning: Remove wax buildup and debris from the tank, conveyor belt, and cooling system.

- Inspection: Check for leaks, loose parts, and worn components.

- Lubrication: Lubricate moving parts to prevent wear and tear.

Troubleshooting common issues:

- Wax not melting: Check the heating system and ensure the wax is at the correct temperature.

- Wax not solidifying: Check the cooling system and ensure it is functioning properly.

- Wax leaking: Check for leaks in the tank, conveyor belt, or cooling system.

4. What are the safety precautions to be taken while operating a Paraffin Machine?

- Wear protective clothing: Gloves, apron, and eye protection are essential.

- Avoid contact with hot wax: The wax can cause severe burns.

- Keep the work area clean: Wax spills can create a slipping hazard.

- Follow all manufacturer’s instructions: For safe operation and maintenance.

5. What are the different grades of paraffin wax and their applications?

Paraffin wax grades vary based on their melting point and viscosity:

- Low-melting point waxes: Used in candles, wax paper, and cosmetics.

- Medium-melting point waxes: Used in food packaging, adhesives, and electrical insulation.

- High-melting point waxes: Used in roofing, waterproofing, and polishes.

6. How do you adjust the temperature and flow rate of a Paraffin Machine?

Temperature control:

- Batch Paraffin Machine: Adjust the temperature of the heating system.

- Continuous Paraffin Machine: Control the temperature of the rollers.

Flow rate control:

- Batch Paraffin Machine: Adjust the speed of the conveyor belt.

- Continuous Paraffin Machine: Control the speed of the rollers.

7. What is the purpose of using a release agent in a Paraffin Machine?

- Prevents the wax from sticking to the conveyor belt or rollers.

- Ensures the smooth flow of wax through the machine.

- Improves the quality of the final wax product.

8. How do you handle and store paraffin wax safely?

- Handling: Use proper lifting techniques and avoid contact with hot wax.

- Storage: Store in a cool, dry place away from ignition sources.

- Disposal: Dispose of used wax according to local regulations.

9. What are the common quality control tests performed on paraffin wax?

- Melting point test: Determines the temperature at which the wax melts.

- Viscosity test: Measures the flow resistance of the wax.

- Color test: Assesses the color and clarity of the wax.

- Penetration test: Measures the hardness of the wax.

10. Describe your experience in operating and maintaining a Paraffin Machine.

Highlight your responsibilities, challenges faced, and any specific techniques or improvements you implemented to enhance the efficiency or safety of the operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paraffin Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paraffin Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paraffin Machine Operators play a key role in producing paraffin wax, an essential component in various industries. Their responsibilities include:

1. Machine Operation

Operators are entrusted with monitoring and controlling paraffin machines throughout the production process. This involves ensuring optimal temperatures, pressures, and flows while maintaining equipment safety and efficiency.

2. Raw Material Management

They are responsible for receiving and inspecting raw materials, such as crude oil and solvents, to ensure they meet quality specifications. Additionally, they prepare and blend these materials according to established recipes.

3. Monitoring and Inspection

Operators constantly monitor the production process, observing key parameters and making adjustments to maintain product quality. They conduct regular inspections of equipment and take samples for testing to ensure compliance with standards.

4. Maintenance and Troubleshooting

They are expected to perform routine maintenance, such as cleaning, lubrication, and minor repairs, to keep the equipment in good working order. They also identify and troubleshoot any problems that arise, ensuring minimal downtime and maintaining productivity.

Interview Preparation Tips

To ace your interview for a Paraffin Machine Operator position, consider employing the following tips:

1. Highlight Relevant Experience

Emphasize your experience in operating and maintaining industrial machinery, particularly in the oil and gas industry. Showcase your knowledge of paraffin production processes and quality control measures.

2. Discuss Problem-Solving Abilities

Interviews will be interested in your ability to troubleshoot and resolve technical issues. Describe instances where you identified and solved problems related to equipment performance or production quality.

3. Demonstrate Attention to Detail

Paraffin production requires meticulous attention to detail. Highlight your strong observational skills and ability to detect and rectify minor deviations in processes or equipment operation.

4. Research the Industry

Show your knowledge of the paraffin industry by researching the latest trends and advancements. This demonstrates your enthusiasm and commitment to staying updated in your field.

5. Prepare Relevant Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions related to the company’s production processes, safety protocols, or opportunities for professional development.

6. Practice Your Presentation

Rehearse your answers to common interview questions, focusing on delivering your responses clearly and concisely. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paraffin Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.