Feeling lost in a sea of interview questions? Landed that dream interview for Part Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Part Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

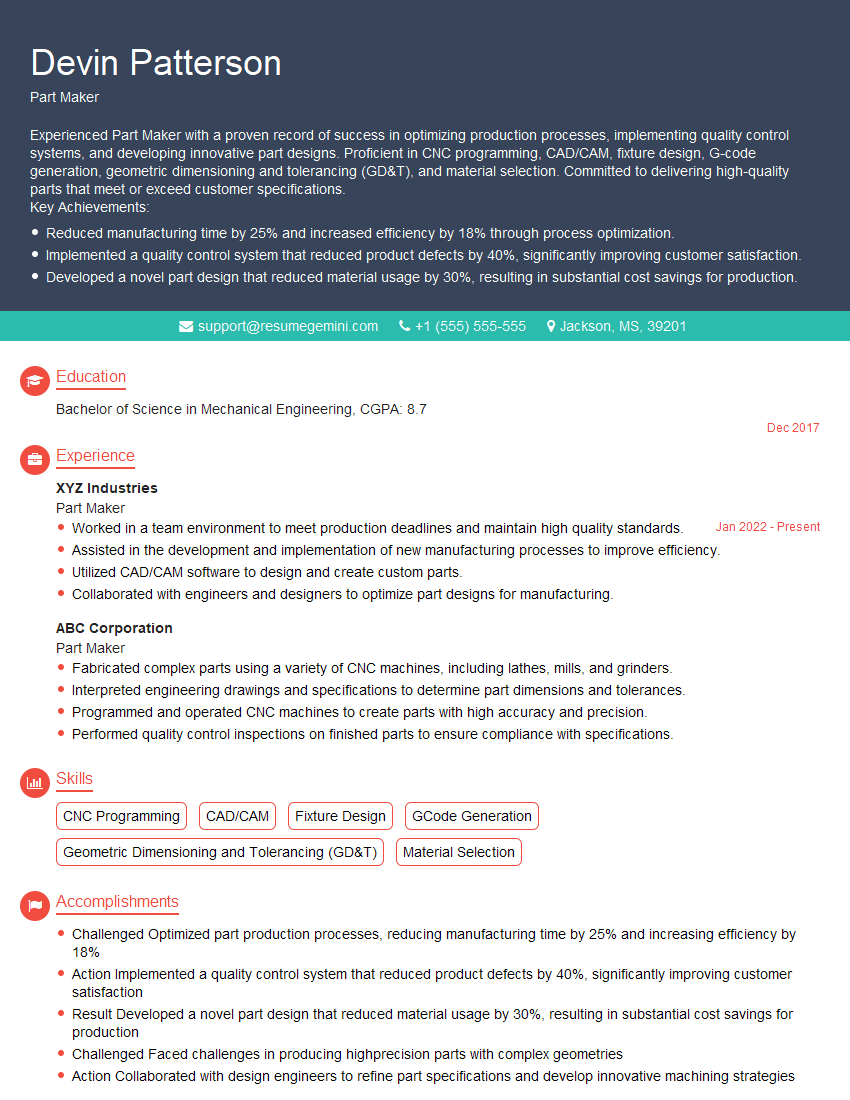

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Part Maker

1. How do you design a 3D model of a part using computer-aided design (CAD) software?

- Begin with a new CAD file and determine the type of model, such as solid, surface, or wireframe.

- Use the CAD software’s tools to sketch the 2D geometry, including lines, arcs, circles, and splines, to create the basic shape of the part.

- Extrude or revolve the 2D sketch to generate the 3D form of the part.

- Add details and features using commands such as fillets, chamfers, holes, and threads.

- Create assemblies by combining multiple parts and defining constraints and relationships between them.

- Generate technical drawings from the 3D model that include orthographic views, sections, and dimensions.

2. What are the different types of 3D printing technologies and their applications?

Fused Deposition Modeling (FDM)

- Uses a thermoplastic filament that is melted and extruded through a nozzle to create layers.

- Applications include prototyping, low-volume production, and hobbyist projects.

Stereolithography (SLA)

- Employs a laser to cure liquid resin, creating solid objects layer by layer.

- Produces highly detailed and accurate parts suitable for prototyping, dental models, and jewelry.

Selective Laser Sintering (SLS)

- Utilizes a laser to fuse powdered material, such as nylon or metal, into a solid form.

- Applications include rapid prototyping, functional prototyping, and end-use parts.

Multi-Jet Modeling (MJP)

- Uses multiple inkjet nozzles to deposit droplets of liquid photopolymer that are cured by ultraviolet light.

- Produces smooth, high-resolution parts suitable for prototyping and concept modeling.

3. Describe the post-processing techniques used in 3D printing and their significance.

- Support Removal: Removing support structures used during printing to provide stability to overhangs and complex geometries.

- Smoothing: Using chemical or mechanical methods to reduce surface roughness, improve aesthetics, and enhance functional properties.

- Coloring: Applying dyes or paints to enhance the visual appeal or provide specific functional properties.

- Infiltration: Filling the pores of printed parts with epoxy or other materials to improve strength and durability.

- Annealing: Heat treating the printed parts to relieve internal stresses and improve mechanical properties.

4. How do you optimize the design of a 3D model for 3D printing?

- Minimize Overhangs: Design parts with minimal overhangs to avoid the need for support structures.

- Consider Wall Thickness: Ensure that the walls of the part are thick enough to provide sufficient strength and prevent warping.

- Orient Parts Properly: Position the part optimally on the print bed to minimize overhangs and optimize material usage.

- Use Fillets and Chamfers: Incorporate fillets and chamfers to reduce stress concentrations and improve part strength.

- Select Appropriate Materials: Choose a 3D printing material that meets the specific requirements of the part, such as strength, flexibility, or temperature resistance.

5. Explain the principles of finite element analysis (FEA) and its applications in part design.

- Discretization: Dividing the part into smaller elements to simplify the analysis.

- Application of Loads and Constraints: Defining the forces, moments, and supports acting on the part.

- Solution: Using mathematical equations to calculate the stresses, strains, and deformations within each element.

- Post-Processing: Visualizing and interpreting the results to assess the performance of the part under different loading conditions.

- Applications: Optimizing part design, predicting structural behavior, and evaluating fatigue life.

6. Describe the process of rapid tooling and its advantages in part manufacturing.

- Creating a Master Pattern: Using 3D printing or CNC machining to fabricate a master pattern of the desired part.

- Mold Making: Fabricating a mold around the master pattern using materials such as silicone or metal.

- Injection Molding: Using the mold to produce parts quickly and efficiently through injection molding.

- Advantages:

- Reduced lead time compared to traditional tooling.

- Lower cost for low-volume production.

- Increased design flexibility and customization.

- Suitable for complex geometries and intricate details.

7. How do you ensure quality control in part manufacturing?

- Dimensional Inspection: Using coordinate measuring machines (CMMs) or other tools to verify dimensions and tolerances.

- Material Testing: Conducting mechanical testing, such as tensile tests and hardness tests, to assess the material properties of the parts.

- Surface Inspection: Examining the surface finish of the parts for defects, scratches, or other imperfections.

- Functional Testing: Testing the parts under actual operating conditions to ensure they meet performance requirements.

- Statistical Process Control (SPC): Monitoring and analyzing production processes to identify and correct any variations that could affect part quality.

8. Describe your experience with additive manufacturing technologies and their capabilities.

I have extensive experience with various additive manufacturing technologies, including FDM, SLA, and SLS. I am proficient in using CAD software to design 3D models, optimize them for printing, and generate toolpaths.

I have successfully produced high-quality prototypes, functional parts, and production-grade components using these technologies. I am also familiar with post-processing techniques and have experience in conducting quality control inspections to ensure parts meet specifications.

9. How do you stay updated on the latest advancements in part manufacturing technologies?

I stay updated on the latest advancements in part manufacturing technologies through various channels:

– Attending industry conferences and workshops

– Reading technical journals and research papers

– Participating in online forums and discussion groups

– Collaborating with experts and thought leaders in the field

– Exploring new materials and technologies through hands-on experimentation

10. Tell me about a challenging part manufacturing project you worked on and how you overcame the challenges.

In one project, I was tasked with manufacturing a complex prototype for a new medical device. The part had intricate internal channels and required high precision and surface finish.

– I began by optimizing the 3D model for SLS printing to minimize support structures and potential defects.

– I worked closely with the design team to refine the tolerances and ensure the part met the functional requirements.

– During post-processing, I developed a customized chemical smoothing technique to achieve the desired surface finish without compromising the structural integrity of the part.

– The final prototype met all the specifications and was used for further testing and development of the medical device.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Part Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Part Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Part makers are responsible for a wide range of tasks in the manufacturing process. They work with a variety of machines and tools to create parts that meet the specifications of their customers. Some of the key job responsibilities of a part maker include:

1. Setting up and operating machinery

Part makers must be able to set up and operate a variety of machines, including lathes, mills, grinders, and drill presses. They must also be able to read and interpret blueprints and other technical drawings.

- Setting up and operating CNC machines

- Installing and replacing cutting tools

- Monitoring the operation of machinery

2. Inspecting parts

Part makers must be able to inspect parts to ensure that they meet the required specifications. They must be able to identify defects and take corrective action.

- Inspecting parts for defects

- Measuring parts to ensure they meet specifications

- Using precision measuring instruments

3. Maintaining equipment

Part makers must be able to maintain the equipment they use. They must be able to identify problems and make repairs.

- Performing routine maintenance on machinery

- Troubleshooting and repairing equipment

- Ordering and replacing parts

4. Working with other team members

Part makers often work as part of a team. They must be able to communicate effectively with other team members and work together to achieve common goals.

- Working with engineers and designers

- Collaborating with other part makers

- Working with customers

Interview Tips

Preparing for an interview can be stressful, but it doesn’t have to be. Here are a few tips to help you ace your next interview for a part maker position:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you learn about their culture, their products, and their values. It will also help you answer questions about the company in a way that shows you’re interested and prepared.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, regardless of the position you’re interviewing for. It’s a good idea to practice answering these questions in advance so that you can be confident and articulate during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you have to wear a suit and tie, but you should at least dress in clean, pressed clothes. You should also avoid wearing anything too revealing or distracting.

- Wear a button-down shirt and slacks

- Wear a skirt or dress that is knee-length or longer

- Wear closed-toe shoes

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the position and the company. They also want to hire people who are positive and upbeat. So make sure to show your enthusiasm and positivity during your interview.

- Smile and make eye contact with the interviewer

- Be positive and upbeat in your answers

- Ask questions about the position and the company

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Part Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.