Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Partition Making Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

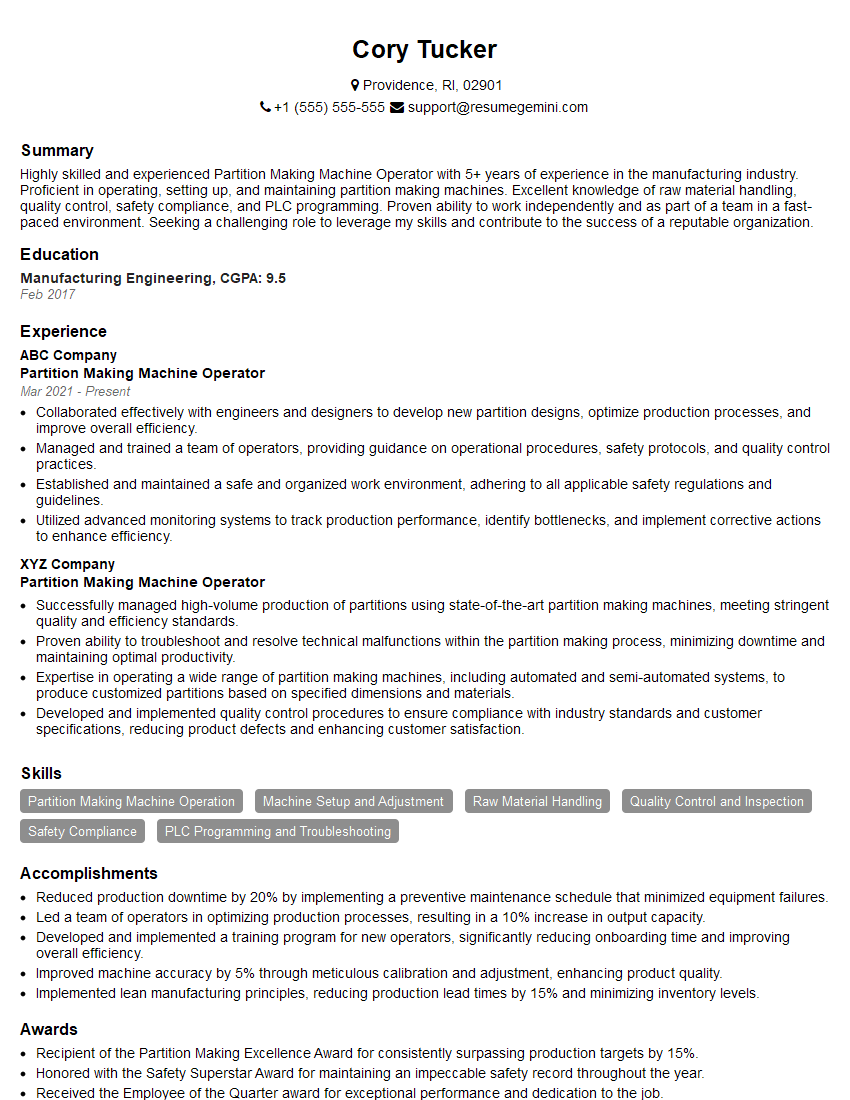

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Partition Making Machine Operator

1. Explain the working principle of a partition making machine?

The partition making machine operates on the principle of sheet feeding, glue application, and pressing. Here’s a detailed overview of the process:

- Sheet Feeding: Sheets of desired material, such as cardboard or chipboard, are fed into the machine.

- Glue Application: The machine applies glue to the edges or surfaces of the sheets where the partitions will be formed.

- Pressing: The glued sheets are pressed together to form the partitions. The pressure applied helps bond the sheets firmly.

2. Describe the different types of partitions that can be made using a partition making machine?

Types of Partitions

- Single-wall partitions: These are basic partitions made from a single layer of material.

- Double-wall partitions: These are more durable partitions made from two layers of material glued together.

- Honeycomb partitions: These partitions feature a honeycomb-shaped core structure sandwiched between two layers of material, providing high strength and low weight.

- Custom partitions: These partitions are designed and manufactured to meet specific customer requirements.

3. What are the key parameters to consider when setting up a partition making machine?

The key parameters to consider when setting up a partition making machine include:

- Sheet thickness: The thickness of the sheets being used.

- Glue type and amount: The type and amount of glue used for bonding the sheets.

- Pressure settings: The pressure applied during the pressing process.

- Drying time: The time required for the glue to dry and bond the sheets firmly.

4. How do you ensure the accuracy and precision of the partitions produced by the machine?

To ensure accuracy and precision, I follow these steps:

- Regular machine calibration: Calibrating the machine regularly ensures that it operates within specified tolerances.

- Use of precision tools: I use accurate measuring and cutting tools to ensure precise dimensions of the partitions.

- Quality control checks: Throughout the production process, I conduct quality checks to identify and rectify any deviations from specifications.

5. What are some common maintenance tasks for a partition making machine?

Regular maintenance tasks for a partition making machine include:

- Cleaning: Keeping the machine clean of dust, glue residue, and other debris.

- Lubrication: Lubricating moving parts to ensure smooth operation.

- Checking glue system: Inspecting and cleaning the glue system to ensure proper glue application.

- Inspecting safety features: Verifying the functionality of safety devices, such as guards and emergency stops.

6. Troubleshooting: How would you address a situation where the machine is producing defective partitions?

To troubleshoot defective partition production, I would follow a systematic approach:

- Identify the specific defect (e.g., misalignment, weak bonding, etc.).

- Check machine settings and parameters to ensure they are within specifications.

- Inspect materials (sheets, glue) for any defects or inconsistencies.

- Perform thorough machine maintenance to address any mechanical issues.

- Calibrate the machine if necessary.

- Conduct test runs and adjust settings until the machine produces acceptable partitions.

7. Describe your experience in optimizing the efficiency of a partition making machine?

In my previous role, I implemented several measures to optimize the efficiency of the partition making machine:

- Improved machine setup: I optimized the feeding, gluing, and pressing processes to reduce setup time.

- Automated processes: I automated certain machine functions, such as glue application and sheet alignment, to increase throughput.

- Reduced waste: I implemented quality control measures to minimize defective partitions, reducing material waste.

- Preventive maintenance: By following a regular maintenance schedule, I proactively addressed potential machine issues, minimizing downtime.

8. How do you stay updated with the latest technological advancements in partition making machines?

To stay updated with technological advancements, I:

- Attend industry events and conferences: I participate in workshops and seminars related to partition making technology.

- Read technical publications: I subscribe to industry magazines and journals to stay informed about new developments.

- Research online: I explore websites and forums to learn about innovative solutions and best practices.

- Network with peers: I connect with other professionals in the field to exchange knowledge and insights.

9. Can you describe a time when you had to work under tight deadlines to deliver a large order of partitions?

In my previous job, I faced a situation where we had to deliver a large order of partitions within a short timeframe. To meet the deadline, I:

- Prioritized tasks: I identified the most critical tasks and allocated resources accordingly.

- Optimized production: I streamlined the production process to reduce bottlenecks and maximize efficiency.

- Communicated effectively: I kept my team and stakeholders informed of progress and any potential challenges.

- Leveraged resources: I sought assistance from colleagues and external vendors when necessary.

As a result, we were able to deliver the order on time and meet the customer’s expectations.

10. Why are you interested in working as a Partition Making Machine Operator in our company?

I am eager to join your company as a Partition Making Machine Operator because:

- Industry reputation: Your company is known for its commitment to quality and innovation in the packaging industry.

- State-of-the-art equipment: I am impressed by your investment in advanced partition making machines.

- Growth opportunities: I believe that your company provides excellent opportunities for professional development and career advancement.

- My skills and experience: I am confident that my skills and experience in partition making machine operation would be a valuable asset to your team.

I am excited by the prospect of contributing to your company’s success and delivering exceptional products to your customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Partition Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Partition Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Partition Making Machine Operators play a vital role in manufacturing industries, operating specialized machinery to create partitions and structural components for various products like furniture, wall panels, and display units.

1. Machine Operation

The primary responsibility involves setting up and operating partition making machines as per production schedules and specifications.

- Loading and unloading raw materials, including sheets of wood, plastic, or metal, onto the machine.

- Adjusting machine settings, such as speed, pressure, and temperature, to meet production requirements.

- Monitoring the machine during operation, ensuring smooth functioning and adherence to quality standards.

2. Quality Control

Operators are responsible for maintaining product quality throughout the production process.

- Inspecting partitions for defects, such as scratches, dents, or incorrect dimensions.

- Making adjustments to the machine or process as needed to resolve quality issues.

- Maintaining a clean and organized work area to minimize errors and maintain quality standards.

3. Maintenance and Troubleshooting

Basic maintenance and troubleshooting are crucial to ensure efficient machine operation and minimize downtime.

- Performing routine maintenance tasks, such as cleaning, lubricating, and inspecting the machine.

- Identifying potential problems or malfunctions and taking prompt corrective actions.

- Reporting any major issues or repairs to the supervisor or maintenance crew.

4. Safety and Compliance

Adhering to safety regulations and maintaining a safe work environment are essential.

- Wearing appropriate safety gear, including gloves, safety glasses, and earplugs.

- Following established safety procedures and protocols to prevent accidents.

- Reporting any safety concerns or hazards to ensure a safe workplace for themselves and colleagues.

Interview Tips

Preparing for a Partition Making Machine Operator interview requires a combination of technical knowledge, attention to detail, and enthusiasm for manufacturing.

1. Research the Role and Company

Familiarize yourself with the specific responsibilities of the role and the company’s products, values, and industry reputation.

- Visit the company’s website to gather information about their business, mission, and recent developments.

- Research the partition making industry, including common materials, processes, and quality standards.

2. Highlight Relevant Experience

Emphasize your previous experience operating partition making machines or similar manufacturing equipment.

- Describe your responsibilities, achievements, and any challenges you encountered in previous roles.

- Quantify your results whenever possible, using specific metrics to demonstrate your impact on productivity or quality.

3. Showcase Technical Skills

Demonstrate your understanding of the technical aspects of partition making, including:

- Different types of partition making machines and their capabilities.

- Relevant materials and their properties.

- Quality control techniques and industry standards.

4. Emphasize Quality and Safety

Partition Making Machine Operators play a crucial role in maintaining quality and safety in manufacturing. Highlight your commitment to:

- Adhering to quality standards and identifying potential defects.

- Following safety protocols and maintaining a safe work environment.

- Taking proactive measures to minimize errors and maintain productivity.

5. Show Enthusiasm and Motivation

Express your interest in the manufacturing industry and your desire to contribute to the company’s success.

- Explain why you’re passionate about working as a Partition Making Machine Operator.

- Share your eagerness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Partition Making Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.