Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Passenger Tire Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

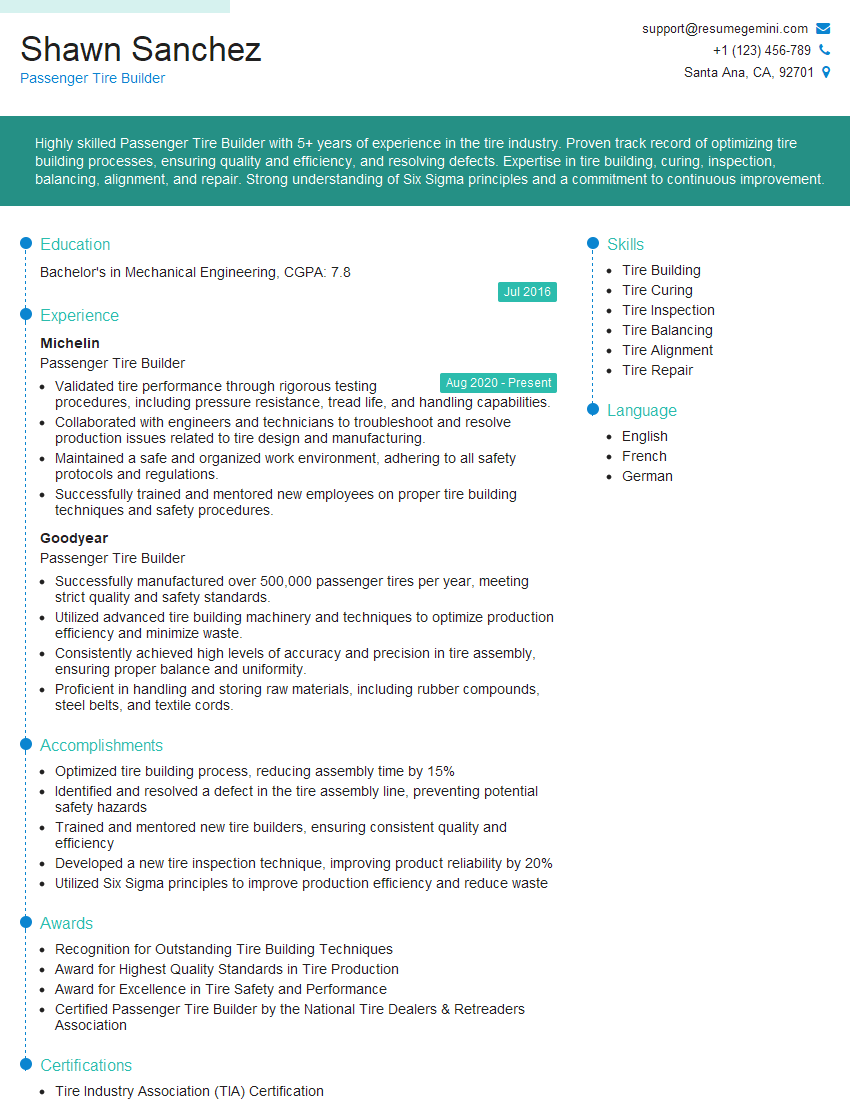

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Passenger Tire Builder

1. Explain the process of building a passenger tire?

The process of building a passenger tire involves several key steps:

- Mixing: Raw materials such as rubber, carbon black, and silica are mixed together to create a compound.

- Extrusion: The compound is extruded through a die to form the tread, sidewalls, and bead.

- Calendering: The extruded components are passed through heated rollers to shape and smooth the surfaces.

- Assembly: The components are assembled on a tire-building machine, with bead wires inserted into the sidewalls.

- Vulcanization: The assembled tire is placed in a mold and subjected to high heat and pressure to cure the rubber and bond the components together.

- Inspection: The finished tire is inspected for defects and meets quality standards.

2. What are the key specifications for a passenger tire?

Dimensions:

- Diameter

- Width

- Aspect ratio

Performance Characteristics:

- Speed rating

- Load index

- Traction

- Durability

- Fuel efficiency

3. What is the difference between a radial and a bias-ply tire?

Radial Tire:

- The cords in the tire’s body run radially from the bead to the bead, perpendicular to the tread.

- Provides better stability, handling, and fuel efficiency.

Bias-Ply Tire:

- The cords in the tire’s body are arranged diagonally, crossing each other at an angle.

- Less expensive to manufacture but has less stability and handling capabilities.

4. What are the common defects found in passenger tires?

- Tread wear

- Sidewall cracks

- Bead damage

- Punctures

- Bulges

5. What is the importance of tire balance and alignment?

Tire Balance:

- Distributes the weight of the tire evenly around the rim.

- Reduces vibrations, improves ride comfort, and extends tire life.

Tire Alignment:

- Ensures that the tires are parallel to each other and perpendicular to the ground.

- Improves vehicle handling, fuel efficiency, and tire wear.

6. What are the safety precautions to take when working with tires?

- Wear appropriate safety gear (gloves, safety glasses, etc.).

- Use proper lifting techniques to avoid injury.

- Never stand in front of an inflating tire.

- Inspect tires regularly for defects or damage.

- Never attempt to repair a damaged tire without proper training.

7. How do you troubleshoot a flat tire?

To troubleshoot a flat tire, you should:

- Inspect the tire for any visible punctures or damage.

- Check the tire pressure using a tire gauge.

- If the tire is underinflated, inflate it to the recommended pressure.

- If the tire is still flat, it may need to be repaired or replaced.

8. What are the different types of tire repair methods?

- Plugging: Inserting a plug into the puncture to seal the leak.

- Patching: Applying a patch over the puncture from the inside of the tire.

- Vulcanization: Using heat and pressure to bond a patch to the tire from the inside.

9. What is your experience in using tire-building equipment?

I have experience using various tire-building equipment, including:

- Tire-building machines

- Tire balancers

- Tire aligners

- Tire changers

10. How do you maintain a clean and organized tire-building work area?

- Regularly clean and sweep the work area.

- Keep tools and equipment in designated places.

- Dispose of scrap materials properly.

- Inspect equipment regularly and make necessary repairs.

- Follow established safety protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Passenger Tire Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Passenger Tire Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Passenger Tire Builder is responsible for the assembly and production of passenger tires within a manufacturing environment. Their duties may vary depending on the specific job description, but some core responsibilities typically include:

1. Tire Assembly

Assembling passenger tires by following established procedures and safety guidelines.

- Positioning and aligning tire components, such as the tread, sidewalls, and bead.

- Applying adhesives and curing agents to ensure proper bonding.

- Operating and maintaining assembly machines and equipment.

2. Quality Control

Inspecting tires during and after assembly to ensure they meet quality standards.

- Checking for defects, such as air leaks, tread irregularities, and improper curing.

- Using measuring instruments and gauges to verify tire dimensions and specifications.

- Reporting any quality issues and taking corrective actions as needed.

3. Machine Operation

Operating and maintaining tire assembly machines, including bead setters, tire builders, and curing presses.

- Adjusting machine settings and parameters to achieve optimal performance.

- Monitoring machine operations and troubleshooting any issues that may arise.

- Performing routine maintenance and cleaning tasks to ensure equipment longevity.

4. Production Optimization

Contributing to production efficiency and meeting production targets by minimizing downtime and optimizing processes.

- Identifying areas for improvement and implementing efficiency measures.

- Working with colleagues to streamline assembly procedures and reduce lead times.

- Maintaining a clean and organized work environment to facilitate smooth operations.

Interview Tips

Preparing for a job interview as a Passenger Tire Builder requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help candidates ace their interview:

1. Research the Company and Role

Take the time to research the company’s background, products, and culture. Understand their specific tire manufacturing processes and the role of the Passenger Tire Builder within their operation.

- Visit the company’s website, social media pages, and industry news articles.

- Review the job description thoroughly to identify the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in tire assembly, quality control, and machine operation. Describe specific examples from your previous experience that demonstrate your abilities.

- Quantify your accomplishments whenever possible, using numbers or percentages to show the impact of your work.

- Discuss your understanding of tire manufacturing processes and your ability to identify and resolve production issues.

3. Demonstrate Safety Awareness

Tire manufacturing involves the use of heavy machinery and hazardous materials. Highlight your commitment to safety and your understanding of industry regulations.

- Describe your experience in following safety protocols and wearing appropriate personal protective equipment (PPE).

- Discuss your knowledge of tire handling and storage procedures to minimize risks.

4. Emphasize Teamwork and Communication

Passenger Tire Builders often work as part of a team, and effective communication is crucial. Show that you are a team player and can collaborate with others to achieve common goals.

- Give examples of how you have worked with colleagues to solve problems or improve processes.

- Describe your communication style and how you ensure that information is clearly understood.

5. Show Enthusiasm and Commitment

Convey your interest in the tire industry and your eagerness to contribute to the company’s success. Show that you are committed to learning and growing in the role.

- Discuss your knowledge of industry trends and emerging technologies.

- Express your willingness to work overtime or on weekends to meet production demands.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Passenger Tire Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.