Are you gearing up for an interview for a Paste Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Paste Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

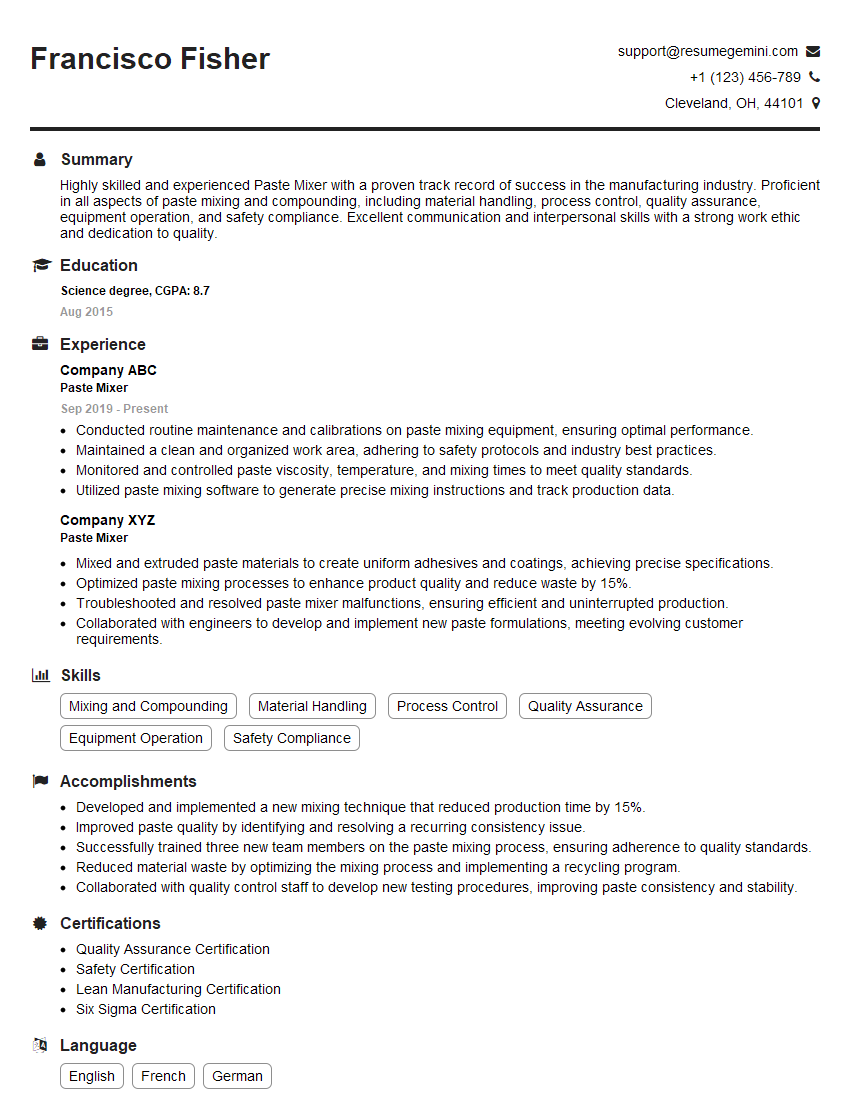

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paste Mixer

1. What are the key responsibilities of a Paste Mixer?

The key responsibilities of a Paste Mixer include:

- Mixing and blending different types of pastes and ingredients to create a uniform mixture.

- Operating and maintaining paste mixing equipment, such as mixers, blenders, and pumps.

- Monitoring the mixing process and making adjustments to ensure the desired consistency and quality of the paste.

- Cleaning and sanitizing mixing equipment and work areas to maintain a clean and safe work environment.

- Following established safety protocols and procedures to prevent accidents and injuries.

2. What types of paste mixing equipment have you operated?

I have operated a variety of paste mixing equipment, including:

- Horizontal and vertical mixers

- Batch and continuous mixers

- High-shear and low-shear mixers

- Blenders

- Pumps

3. What factors do you consider when selecting the appropriate mixing equipment for a particular paste?

When selecting the appropriate mixing equipment for a particular paste, I consider the following factors:

- The type of paste

- The desired consistency and quality of the paste

- The production volume

- The available space

- The budget

4. How do you ensure that the paste is mixed to the desired consistency and quality?

I monitor the mixing process closely and make adjustments as needed to ensure that the paste is mixed to the desired consistency and quality. I also use a variety of testing methods to verify the quality of the paste, such as:

- Visual inspection

- Rheological testing

- Chemical analysis

5. What are the most common problems that you have encountered in paste mixing and how did you resolve them?

The most common problems that I have encountered in paste mixing include:

- Improper mixing: This can be caused by a variety of factors, such as using the wrong mixing equipment or not mixing the paste for long enough. I resolve this problem by troubleshooting the mixing process and making the necessary adjustments.

- Inconsistent quality: This can be caused by a variety of factors, such as variations in the raw materials or the mixing process. I resolve this problem by identifying the source of the variation and implementing corrective actions.

- Equipment breakdowns: This can be caused by a variety of factors, such as wear and tear or improper maintenance. I resolve this problem by troubleshooting the equipment and repairing or replacing the faulty components.

6. What are your thoughts on automation in paste mixing?

I believe that automation can play a significant role in improving the efficiency and quality of paste mixing. Automation can help to reduce labor costs, improve product consistency, and increase production capacity. I am familiar with a variety of automated paste mixing systems and I am confident that I can implement and maintain these systems in a production environment.

7. What are the safety hazards associated with paste mixing and how do you mitigate them?

The safety hazards associated with paste mixing include:

- Exposure to hazardous chemicals: Many pastes contain hazardous chemicals, such as solvents and acids. I mitigate this hazard by wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a respirator.

- Burns: Paste mixing equipment can generate heat, which can cause burns. I mitigate this hazard by wearing appropriate PPE and by keeping the mixing area well-ventilated.

- Slips and falls: The mixing area can be wet and slippery. I mitigate this hazard by wearing appropriate footwear and by keeping the area clean and dry.

8. What are your career goals and how does this position align with them?

My career goal is to become a Production Manager in the manufacturing industry. I believe that this position will provide me with the opportunity to develop the skills and experience necessary to achieve my goal. I am eager to learn more about paste mixing and to contribute to the success of your company.

9. What is your understanding of the company’s quality standards?

I understand that the company has high quality standards and is committed to producing a consistent, high-quality product. I am familiar with the company’s quality control procedures and I am confident that I can meet the company’s quality standards.

10. Do you have any questions for us?

I would like to know more about the company’s production process and how the Paste Mixer position fits into the overall process. I would also like to know more about the company’s training and development opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paste Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paste Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paste Mixers are responsible for preparing and mixing various types of pastes, adhesives, and other materials used in manufacturing and construction industries.

1. Mixing Materials

Prepare and mix pastes, adhesives, and other materials according to specified formulas and proportions.

- Read and interpret mix design specifications and instructions.

- Weigh, measure, and combine raw materials accurately using various mixing equipment.

2. Operating Mixing Equipment

Operate and maintain a variety of mixing equipment such as mixers, blenders, and agitators.

- Set up and calibrate equipment to ensure optimum mixing performance.

- Monitor mixing processes and adjust parameters as needed to achieve desired consistency.

3. Quality Control

Perform quality control tests on mixed materials to ensure they meet specifications.

- Conduct physical and chemical tests such as viscosity, pH, and solids content.

- Record and document test results for quality assurance purposes.

4. Safety and Maintenance

Follow safety protocols and maintain a clean and organized work area.

- Wear appropriate personal protective equipment (PPE) and follow safety guidelines.

- Inspect and maintain mixing equipment regularly to prevent breakdowns and ensure optimal performance.

Interview Tips

Preparing for an interview for a Paste Mixer position requires thorough research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Familiarize yourself with the specific responsibilities and requirements of the Paste Mixer role.

2. Highlight Relevant Skills and Experience

Emphasize your skills in mixing and preparing materials, operating mixing equipment, and conducting quality control tests. Showcase any experience you have in the manufacturing or construction industry.

3. Prepare for Behavioral Questions

Behavioral questions assess your past work behavior and are commonly used in interviews. Practice answering questions about your problem-solving abilities, teamwork experiences, and attention to detail.

4. Practice Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Tailor your answers to the specific requirements of the Paste Mixer role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paste Mixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.