Are you gearing up for an interview for a Pasteurizing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pasteurizing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

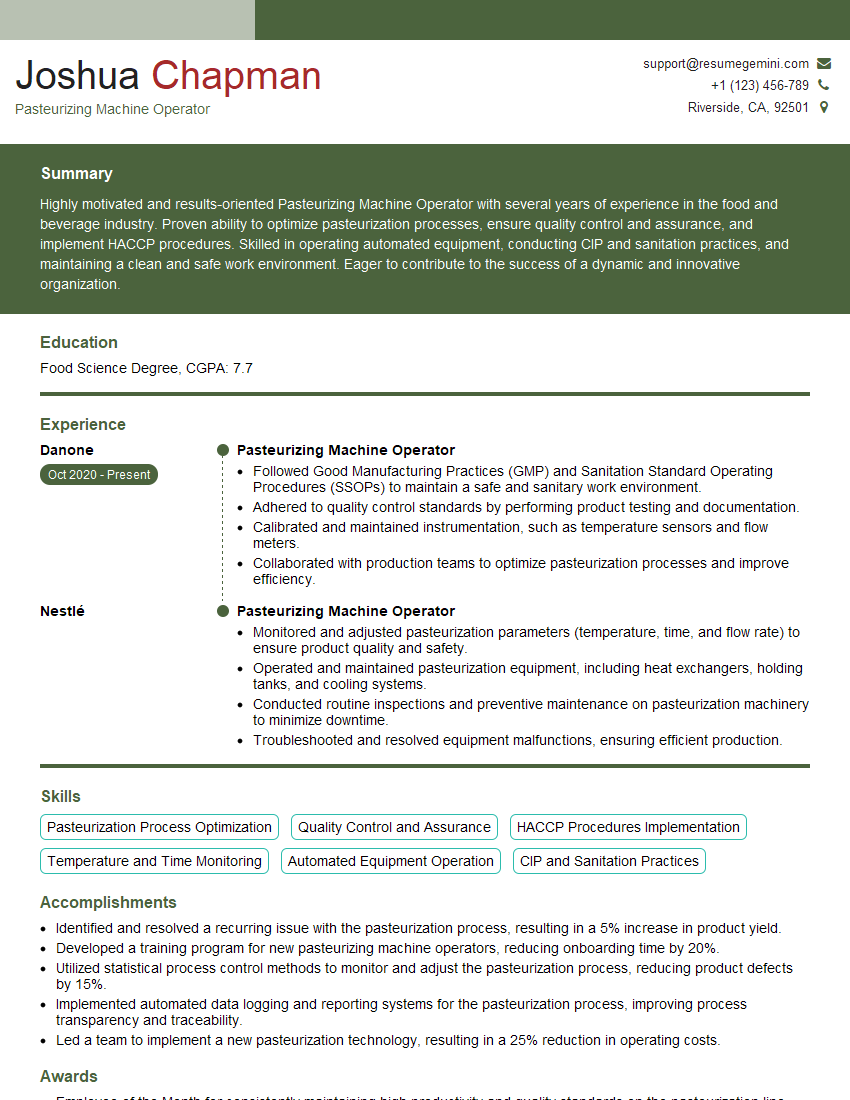

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pasteurizing Machine Operator

1. What is the purpose of pasteurization and how does it work?

- Pasteurization is a process of heating a liquid to kill harmful bacteria and pathogens.

- It works by exposing the liquid to a specific temperature for a specific amount of time, which kills the bacteria but does not damage the liquid itself.

2. Describe the different types of pasteurization methods and their advantages and disadvantages.

- High-temperature, short-time (HTST) pasteurization: Heats the liquid to 72°C (161°F) for 15 seconds. Advantages: Fast and efficient, preserves flavor and nutrients. Disadvantages: May not kill all spores.

- Ultra-high temperature (UHT) pasteurization: Heats the liquid to 135°C (275°F) for 2 seconds. Advantages: Kills all spores, extends shelf life. Disadvantages: May alter flavor and nutrient content.

- Low-temperature, long-time (LTLT) pasteurization: Heats the liquid to 63°C (145°F) for 30 minutes. Advantages: Preserves flavor and nutrients, suitable for delicate products. Disadvantages: Longer process time.

3. What are the critical control points (CCPs) in a pasteurization process and how do you monitor and control them?

- Temperature: Monitor and maintain the correct temperature during pasteurization to ensure effective killing of bacteria.

- Time: Control the duration of pasteurization to ensure sufficient exposure to the desired temperature.

- Flow rate: Ensure the liquid flows through the pasteurizer at the correct rate to achieve uniform heating.

4. How do you calibrate and maintain the temperature sensors used in a pasteurization machine?

- Calibrate temperature sensors regularly using a certified thermometer or reference device.

- Clean and inspect sensors regularly to ensure accuracy and prevent contamination.

- Document calibration and maintenance procedures to ensure traceability and compliance.

5. What are the key factors to consider when selecting a pasteurization machine for a specific application?

- Product type: Consider the viscosity, acidity, and sensitivity of the product to heat.

- Throughput: Determine the desired production capacity and flow rate.

- Type of pasteurization: Choose the appropriate pasteurization method based on product requirements and desired shelf life.

- Sanitation: Ensure the machine is designed for easy cleaning and meets sanitary standards.

6. Describe the procedures for cleaning and sanitizing a pasteurization machine.

- Mechanical cleaning: Disassemble and clean all removable parts using detergents and brushes.

- Chemical sanitization: Apply a food-grade sanitizer to all surfaces and components that come into contact with the product.

- Rinsing: Thoroughly rinse all surfaces with clean water after sanitization.

- Document: Record cleaning and sanitization procedures and any deviations.

7. What are the potential hazards associated with pasteurization and how do you mitigate them?

- Bacterial contamination: Ensure proper sanitation, temperature control, and monitoring to prevent recontamination.

- Spoilage: Use appropriate pasteurization methods and packaging to extend shelf life and prevent spoilage.

- Nutrient loss: Optimize pasteurization conditions to minimize nutrient loss while ensuring bacterial inactivation.

8. Describe your experience with troubleshooting common issues encountered in pasteurization machines.

Provide specific examples of issues encountered, the troubleshooting steps taken, and the solutions implemented.

9. How do you stay updated with the latest advancements in pasteurization technology?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with equipment manufacturers and experts.

10. What are your quality control measures to ensure the safety and quality of pasteurized products?

- Microbial testing: Conduct regular microbiological tests to verify the absence of pathogens.

- Sensory evaluation: Assess taste, odor, and appearance of pasteurized products.

- Adherence to standards: Ensure compliance with food safety regulations and industry best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pasteurizing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pasteurizing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Pasteurizing Machine Operator, your responsibilities will center around the safe and efficient operation of pasteurizing equipment in a food or beverage production facility.

1. Machine Operation and Maintenance

Your core duty involves operating pasteurizing machines according to established procedures to ensure the proper treatment of food products.

- Monitor machine settings, ensuring precise temperature, pressure, and flow rates.

- Inspect and clean equipment regularly to maintain optimal functionality and prevent contamination.

2. Product Quality Control

You will play a crucial role in maintaining product quality by ensuring adherence to pasteurization standards.

- Test and analyze product samples to verify compliance with established quality parameters.

- Identify and address any deviations or quality concerns promptly.

3. Recordkeeping and Reporting

You will be responsible for maintaining accurate records and reporting on machine performance and product quality.

- Document machine operating parameters, cleaning schedules, and any incidents or malfunctions.

- Report any quality issues or production deviations to supervisors.

4. Safety and Compliance

As a Pasteurizing Machine Operator, you will prioritize safety and compliance in all aspects of your work.

- Follow all safety regulations and adhere to established safety protocols.

- Ensure compliance with food safety and quality standards, such as HACCP.

Interview Tips

Preparing for a Pasteurizing Machine Operator interview requires understanding the key responsibilities and demonstrating your relevant skills and experience.

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry practices to demonstrate your interest and knowledge of the field.

- Research the company’s website and industry news to gain insights into their operations and market position.

- Learn about pasteurization techniques, food safety regulations, and quality control practices.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining pasteurization equipment, as well as your understanding of product quality control.

- Provide specific examples of your responsibilities in previous roles, quantifying your accomplishments whenever possible.

- Showcase your attention to detail, problem-solving abilities, and commitment to food safety.

3. Prepare for Technical Questions

Anticipate technical questions about pasteurization processes, machine troubleshooting, and food safety protocols.

- Review basic pasteurization principles, including temperature and time requirements.

- Practice troubleshooting common machine problems and demonstrate your logical approach to resolving issues.

- Familiarize yourself with food safety regulations and best practices, such as HACCP.

4. Convey Your Passion and Motivation

Express your enthusiasm for the role and the food industry. Highlight your passion for ensuring product quality and safety.

- Share your understanding of the importance of pasteurization in safeguarding public health.

- Explain how you envision contributing to the company’s quality and safety goals.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pasteurizing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.