Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Patch Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

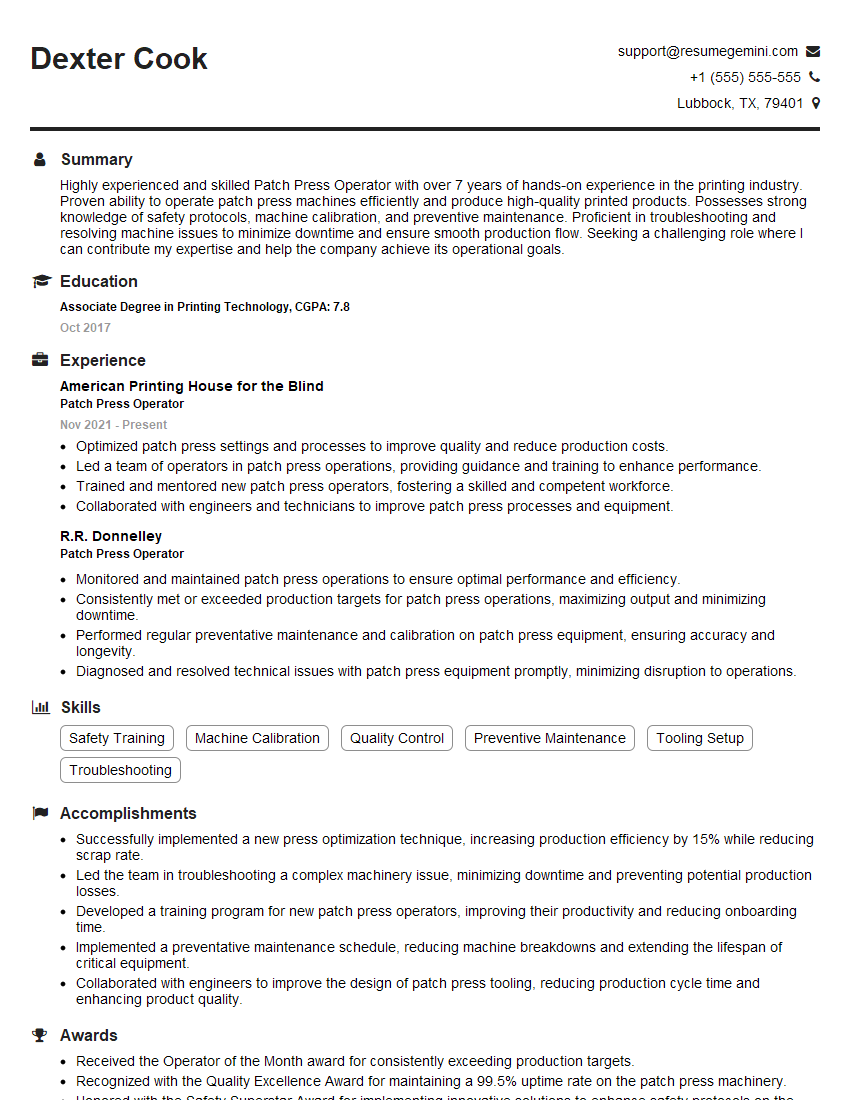

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Patch Press Operator

1. Describe the key responsibilities of a Patch Press Operator?

The key responsibilities of a Patch Press Operator include:

- Operating patch press machines to bond materials such as rubber, fabric, and metal

- Loading and unloading materials, using hand tools or automated equipment

- Inspecting materials before and after pressing to ensure quality standards are met

- Monitoring machine settings and making adjustments as needed to optimize production

- Performing maintenance and repairs on press equipment

2. What are the different types of patch press machines?

The different types of patch press machines include:

- Manually operated presses

- Semi-automatic presses

- Fully automatic presses

- Hot presses

- Cold presses

3. What are the safety precautions that must be taken when operating a patch press machine?

The safety precautions that must be taken when operating a patch press machine include:

- Wearing proper personal protective equipment (PPE), such as safety glasses, gloves, and a lab coat

- Keeping hands and other body parts away from the machine’s moving parts

- Never reaching into the machine while it is in operation

- Following all manufacturer’s instructions for safe operation

- Reporting any malfunctions or safety concerns to a supervisor immediately

4. What are the common problems that can occur when operating a patch press machine?

The common problems that can occur when operating a patch press machine include:

- Misalignment of materials

- Improper bonding

- Machine breakdowns

- Safety hazards

5. How do you troubleshoot and resolve problems with a patch press machine?

To troubleshoot and resolve problems with a patch press machine, I first identify the problem by observing the machine’s operation and the materials being processed.

Once I have identified the problem, I consult the manufacturer’s instructions and use my experience to determine the best course of action.

I then take the necessary steps to resolve the problem, such as adjusting machine settings, replacing worn parts, or performing maintenance.

6. What are the quality control procedures that you follow when operating a patch press machine?

The quality control procedures that I follow when operating a patch press machine include:

- Inspecting materials before and after pressing to ensure they meet quality standards

- Monitoring machine settings and making adjustments as needed to optimize production

- Performing regular maintenance and repairs on press equipment to prevent problems

I also keep a log of all quality control checks and maintenance activities to document my work and ensure that the machine is operating properly.

7. What is your experience with different types of patch press machines?

I have experience with a variety of patch press machines, including manually operated presses, semi-automatic presses, and fully automatic presses.

I am also familiar with different types of materials, such as rubber, fabric, and metal, and I know how to adjust machine settings to optimize bonding for each type of material.

8. What is your experience with troubleshooting and resolving problems with patch press machines?

I have experience troubleshooting and resolving a variety of problems with patch press machines, including misalignment of materials, improper bonding, machine breakdowns, and safety hazards.

I am able to identify the root cause of the problem and take the necessary steps to resolve it quickly and efficiently.

9. What is your experience with quality control procedures for patch press machines?

I am familiar with the quality control procedures for patch press machines and I follow them diligently to ensure that the machines are operating properly and producing high-quality products.

I also keep a log of all quality control checks and maintenance activities to document my work and ensure that the machine is operating properly.

10. What are your strengths and weaknesses as a Patch Press Operator?

Strengths:

- I am a highly skilled and experienced Patch Press Operator with a proven track record of success

- I am proficient in operating a variety of patch press machines

- I am familiar with different types of materials and I know how to adjust machine settings to optimize bonding for each type of material

- I am able to troubleshoot and resolve problems with patch press machines quickly and efficiently

- I am committed to quality and I follow all quality control procedures diligently

Weaknesses:

- I am not yet familiar with the specific patch press machine that is used in your company

- I am not yet familiar with the specific quality control procedures that are used in your company

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Patch Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Patch Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Patch Press Operators are responsible for a variety of tasks in the manufacturing process. Their key job responsibilities include:

1. Operating Patch Press Machine

- Setting up and operating the patch press machine according to specifications.

- Monitoring the machine for proper operation and making adjustments as needed.

- Inspecting patches for quality and ensuring they meet specifications.

2. Preparing Materials

- Gathering and preparing raw materials for the patch press machine.

- Ensuring that the materials meet specifications and are properly loaded into the machine.

3. Maintaining Equipment

- Performing routine maintenance and cleaning on the patch press machine.

- Inspecting the machine for wear and tear and reporting any problems to the supervisor.

- Ordering and installing replacement parts as needed.

4. Quality Control

- Inspecting finished products to ensure they meet quality standards.

- Identifying and correcting any defects in the products.

- Maintaining records of quality inspections and reporting any problems to the supervisor.

5. Safety and Compliance

- Following all safety procedures and regulations.

- Wearing appropriate personal protective equipment (PPE).

- Reporting any safety hazards or accidents to the supervisor.

Interview Preparation Tips

Preparing for a patch press operator interview can help you make a great impression and increase your chances of getting the job. Here are some interview preparation tips:

1. Research the Company and Position

- Visit the company’s website to learn about their products, services, and culture.

- Read the job description carefully and identify the key requirements.

- Research the average salary for patch press operators in your area.

2. Prepare Your Answers to Common Interview Questions

- Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Use the STAR method to answer behavioral questions, which involves describing a Situation, Task, Action, and Result.

- Quantify your accomplishments whenever possible to demonstrate your impact.

3. Highlight Your Skills and Experience

- Make a list of your skills and experience that are relevant to the job, such as your ability to operate a patch press machine, prepare materials, and maintain equipment.

- Provide specific examples of how you have used these skills in your previous roles.

- Be prepared to talk about your strengths and weaknesses, and how they relate to the job.

4. Dress Professionally and Arrive on Time

- First impressions matter, so dress professionally for your interview.

- Arrive on time for your interview and be prepared to wait a few minutes if the interviewer is running behind.

- During the interview, maintain eye contact, speak clearly, and be respectful of the interviewer.

5. Ask Questions at the End of the Interview

- At the end of the interview, take the opportunity to ask the interviewer any questions you have about the position or the company.

- This shows that you are interested in the job and that you have done your research.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Patch Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.