Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pattern Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

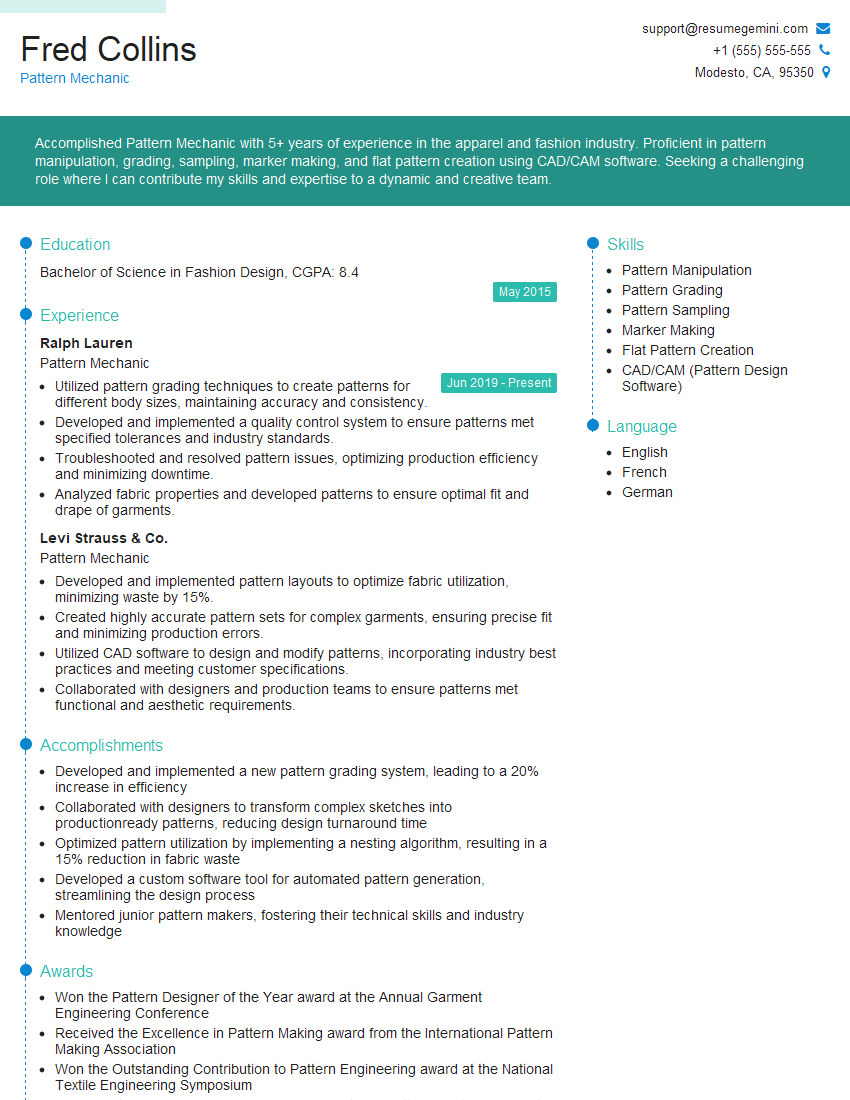

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pattern Mechanic

1. Describe the process of developing a pattern for a new garment?

The process of developing a pattern for a new garment typically involves the following steps:

- Conceptualizing the garment’s design

- Determining the appropriate fabric

- Taking body measurements

- Creating a sketch of the garment

- Developing a prototype pattern

- Testing the prototype on a fit model

- Making necessary adjustments to the pattern

- Creating the final pattern

2. What are the different types of pattern grading?

Manual Grading

- Involves manually adjusting each piece of a pattern to create different sizes

- Time-consuming and requires a high level of skill

Computer-Aided Grading

- Uses software to automatically adjust patterns to different sizes

- More efficient and accurate than manual grading

3. Explain the importance of pattern accuracy in garment manufacturing.

Pattern accuracy is critical in garment manufacturing for several reasons:

- Ensures the garment fits the wearer properly

- Reduces fabric waste by minimizing cutting errors

- Improves production efficiency by allowing for smooth fabric cutting and sewing

- Enhances the overall quality and aesthetic appeal of the garment

4. Describe the use of computer-aided design (CAD) in pattern making.

CAD is widely used in pattern making to:

- Create digital patterns that can be easily edited and modified

- Automate pattern grading and marker making

- Generate production instructions and fabric cutting plans

- Enable collaboration between designers, pattern makers, and manufacturers

5. What are the challenges of working as a pattern mechanic?

Some of the challenges of working as a pattern mechanic include:

- Interpreting design sketches and translating them into accurate patterns

- Ensuring precision in pattern making and grading

- Working under tight deadlines to meet production schedules

- Staying updated with the latest industry trends and technologies

- Understanding the properties of different fabrics and how they affect pattern development

6. Explain the difference between a sloper and a block pattern.

- Sloper: A basic pattern that represents the shape of the human body

- Block Pattern: A modified sloper that includes design details and seam allowances

7. Describe the importance of taking accurate body measurements for pattern making.

Accurate body measurements are essential for pattern making because they:

- Ensure the garment fits the wearer’s body shape

- Help to identify and accommodate any unique body features

- Allow for proper grading of the pattern to create different sizes

- Reduce the need for expensive and time-consuming alterations

8. What are the principles of marker making in garment manufacturing?

Marker making involves optimizing the layout of pattern pieces on fabric to minimize fabric waste. Key principles include:

- Maximizing fabric utilization

- Minimizing pattern overlap

- Accounting for fabric grain and direction

- Considering sewing allowances

9. Explain the concept of pattern matching in garment construction.

Pattern matching involves aligning fabric patterns to create seamless and aesthetically pleasing effects:

- Stripes or plaids: Matching the lines or patterns to ensure continuity

- Prints: Aligning the prints to create a consistent design

- Checks: Matching the checks to create a symmetrical or asymmetrical pattern

10. Describe the role of a pattern mechanic in the garment industry.

A pattern mechanic plays a crucial role in the garment industry by:

- Interpreting design specifications and translating them into patterns

- Developing patterns that meet the design requirements and fit specifications

- Grading patterns to create different sizes

- Testing and refining patterns to ensure accuracy and functionality

- Collaborating with designers, engineers, and production teams

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pattern Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pattern Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pattern Mechanics play a crucial role in the garment industry by creating patterns that serve as blueprints for the production of various apparel items. Their responsibilities encompass a wide range of tasks, including:

1. Pattern Creation and Modification

Pattern Mechanics possess expertise in developing new patterns from scratch or modifying existing ones to meet specific design requirements. They use specialized software and techniques to create precise patterns that define the shape, size, and details of garments.

- Develop patterns for a variety of garments, including dresses, shirts, pants, and jackets.

- Analyze and interpret design specifications to create patterns that align with the desired style and fit.

2. Pattern Grading

Pattern Mechanics are responsible for grading patterns to create different sizes of a garment. They adjust the pattern’s dimensions to ensure a consistent fit across sizes, maintaining the integrity of the design.

- Use mathematical calculations and software tools to grade patterns accurately.

- Create graded patterns that allow for variations in body measurements while preserving the garment’s overall shape.

3. Marker Making

Pattern Mechanics create markers, which are templates used to cut fabric efficiently. They arrange patterns on a marker to maximize fabric utilization and minimize waste. This process requires a deep understanding of fabric properties and cutting techniques.

- Develop markers that optimize fabric usage, reducing material costs.

- Plan marker layouts to minimize fabric waste and ensure efficient cutting.

4. Sample Making

Pattern Mechanics often participate in the sample-making process to ensure that patterns translate effectively into garments. They work closely with designers and sample makers to create prototypes that showcase the garment’s fit, style, and construction.

- Collaborate with designers and sample makers to create accurate samples.

- Identify and resolve any issues with the pattern or fit during the sample-making process.

Interview Tips

To ace an interview for a Pattern Mechanic role, candidates should prepare thoroughly and demonstrate their skills and knowledge in the following areas:

1. Technical Proficiency

Interviewers will assess candidates’ proficiency in pattern-making software and techniques. They will ask questions about the candidate’s experience with specific software programs and their understanding of pattern creation, grading, and marker making.

- Practice creating patterns using industry-standard software.

- Review the principles of pattern grading and marker making.

2. Problem-Solving Abilities

Pattern Mechanics often encounter challenges during the pattern-making process. Interviewers will evaluate candidates’ ability to solve problems creatively and find solutions that meet design specifications while minimizing material waste.

- Prepare examples of how you have solved problems related to pattern creation or grading.

- Explain your approach to resolving fit issues and ensuring garment accuracy.

3. Attention to Detail

Attention to detail is crucial for Pattern Mechanics. Interviewers will assess candidates’ ability to create precise patterns and markers, ensuring that garments are produced with the desired fit and quality.

- Highlight your meticulous work style and commitment to accuracy.

- Provide examples of how you have maintained high levels of precision in your previous roles.

4. Communication and Collaboration

Pattern Mechanics work closely with designers, sample makers, and other team members. Interviewers will evaluate candidates’ communication and collaboration skills to ensure that they can effectively convey their ideas and work harmoniously within a team.

- Emphasize your ability to communicate clearly and effectively.

- Provide examples of how you have collaborated successfully in a team environment.

Next Step:

Now that you’re armed with the knowledge of Pattern Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pattern Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini