Are you gearing up for an interview for a Pattern Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pattern Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

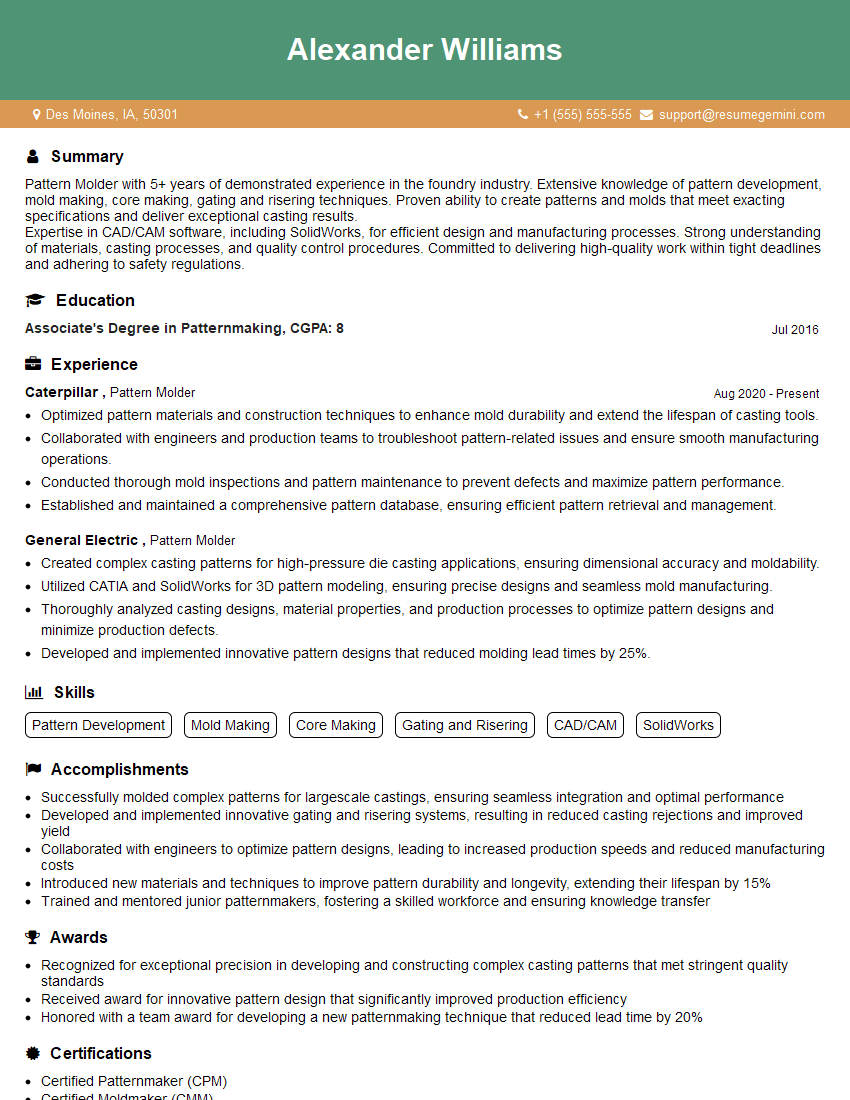

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pattern Molder

1. What is the shrinkage allowance in pattern making? Why is it important?

Shrinkage allowance is the amount of additional material added to a pattern to compensate for the contraction of the metal during cooling and solidification. It is important because it ensures that the finished casting has the correct dimensions and shape.

- It compensates for the contraction of the metal during cooling and solidification.

- It ensures that the finished casting has the correct dimensions and shape.

2. What are the different types of pattern materials used in industry and their applications?

Metals

- Cast iron: Durable and wear-resistant, used for large and heavy patterns.

- Aluminum: Lightweight and easy to machine, used for small and medium-sized patterns.

- Steel: Strong and durable, used for patterns that require high precision.

Wood

- Hardwoods: Oak, maple, and mahogany, used for patterns that require strength and durability.

- Softwoods: Pine, fir, and spruce, used for patterns that are not subjected to heavy loads.

Plastics

- ABS: Durable and impact-resistant, used for patterns that require strength and flexibility.

- Polystyrene: Lightweight and easy to machine, used for disposable patterns.

3. What are the steps involved in pattern making?

- Analyze the part design and determine the pattern requirements.

- Select the appropriate pattern materials and allowances.

- Create a pattern drawing or model.

- Construct the pattern using the appropriate techniques (e.g., machining, casting, molding).

- Inspect the pattern and make necessary adjustments.

4. What are some common defects in patterns and how can they be prevented?

- Warping: Can be prevented by using well-seasoned wood or other stable materials.

- Cracking: Can be prevented by using materials with high tensile strength and avoiding sharp corners.

- Shrinkage: Can be prevented by using materials with low shrinkage rates and providing adequate shrinkage allowance.

5. How do you ensure the accuracy and precision of patterns?

- Use precise measuring and inspection tools.

- Follow established standards and specifications.

- Check patterns regularly for wear and tear.

- Use fixtures and jigs to ensure consistent results.

6. What are some advanced techniques used in pattern making?

- 3D printing: Creates patterns directly from CAD models.

- CNC machining: Automates pattern production and ensures high precision.

- Vacuum forming: Used to create complex patterns from plastic sheets.

7. What are the different types of pattern layout and their advantages?

Single layout

- Advantages

- Simple and easy to create.

- Suitable for small and medium-sized patterns.

Split layout

- Advantages

- Allows for easy molding of complex patterns.

- Reduces the risk of casting defects.

Match plate layout

- Advantages

- Enables simultaneous molding of both sides of the pattern.

- Improves productivity and reduces molding time.

8. What factors influence the choice of pattern layout?

- Complexity of the part design.

- Production volume and casting method.

- Available equipment and resources.

- Cost and lead time considerations.

9. How do you calculate the metal yield for a given pattern?

- Determine the volume of metal required to fill the mold cavity using the pattern dimensions.

- Calculate the weight of the metal using its density.

- Estimate the metal yield by dividing the weight of the required metal by the actual weight of the casting.

10. What are the safety considerations when working with patterns?

- Wear appropriate safety gear (e.g., gloves, eye protection).

- Handle patterns carefully to avoid damage or injury.

- Store patterns securely to prevent accidents.

- Use proper ventilation to avoid exposure to harmful fumes or dust.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pattern Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pattern Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pattern Molders are responsible for creating patterns used in the casting process. They use their knowledge of materials and techniques to create patterns that are accurate and meet the specifications of the customer. Key job responsibilities include:

1. Creating patterns

The primary responsibility of a Pattern Molder is to create patterns. This involves working with engineers and designers to understand the design of the part to be cast, and then creating a pattern that will produce the part to the required specifications.

- Use a variety of materials, including wood, metal, and plastic, to create patterns.

- Use hand and power tools to shape and finish patterns.

- Ensure that patterns are accurate and meet the specifications of the customer.

2. Maintaining patterns

Pattern Molders are also responsible for maintaining patterns. This involves inspecting patterns for wear and tear, and repairing or replacing them as necessary.

- Inspect patterns for wear and tear.

- Repair or replace patterns as necessary.

- Maintain a clean and organized work area.

3. Working with other departments

Pattern Molders work closely with other departments, such as engineering and production. This involves providing feedback on the design of parts, and working with production staff to ensure that patterns are used correctly.

- Provide feedback on the design of parts.

- Work with production staff to ensure that patterns are used correctly.

- Participate in quality control meetings.

4. Staying up-to-date on new techniques and materials

Pattern Molding is a constantly evolving field. New techniques and materials are being developed all the time. Pattern Molders must stay up-to-date on these new developments in order to remain competitive.

- Attend industry workshops and conferences.

- Read trade publications.

- Experiment with new techniques and materials.

Interview Tips

Preparing for an interview for a Pattern Molder position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to an interview, it’s important to do your research. Learn as much as you can about the company and the position you’re applying for. This will help you to answer questions intelligently and show the interviewer that you’re genuinely interested in the job.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Tailor your answers to the specific job you’re applying for.

- Practice answering out loud so that you can get comfortable with the sound of your own voice.

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. Make sure your clothes are clean and wrinkle-free, and that your shoes are polished.

- Choose clothes that are appropriate for the company culture.

- Make sure your clothes fit well.

- Pay attention to details, such as your hair and nails.

4. Be on time

Punctuality is a sign of respect, so make sure to arrive for your interview on time. If you’re running late, call the interviewer to let them know. It’s also a good idea to arrive at the interview location a few minutes early so that you have time to relax and compose yourself.

- Allow yourself plenty of time to travel to the interview.

- Factor in potential delays, such as traffic or construction.

- Leave early so that you have time to spare.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pattern Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pattern Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.