Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pattern Wheel Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

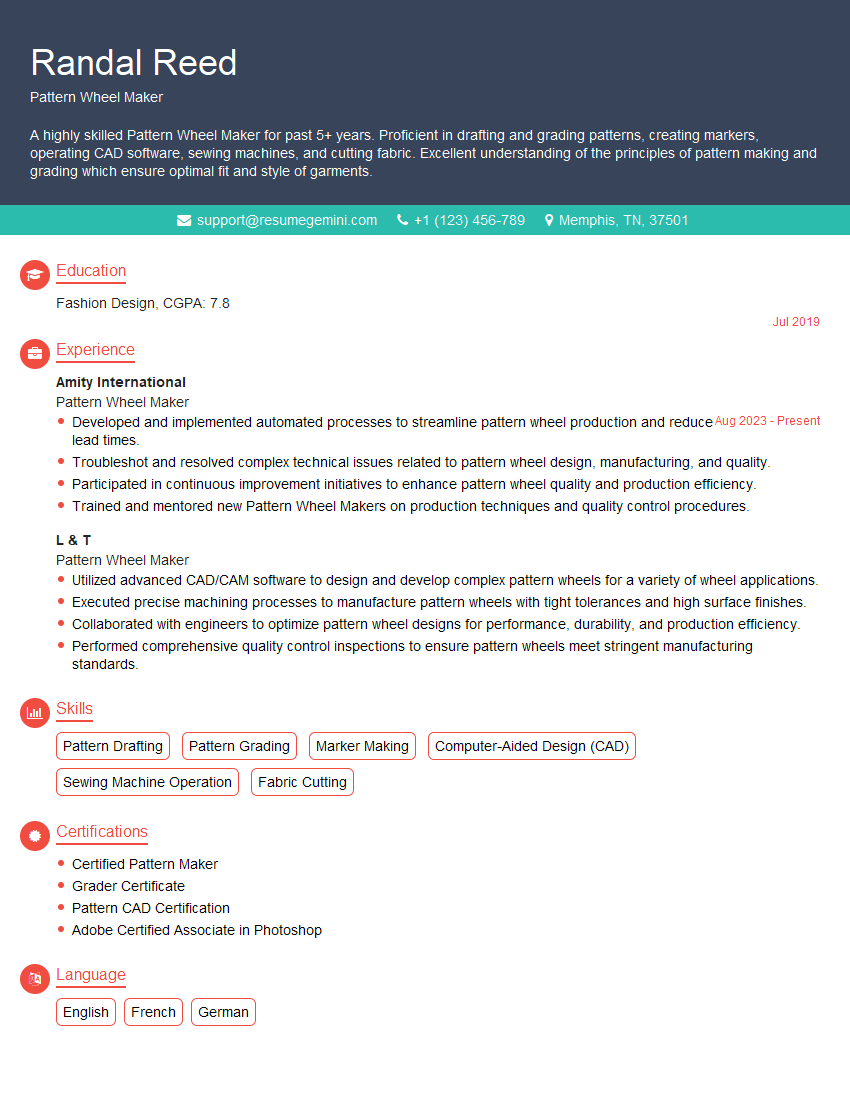

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pattern Wheel Maker

1. What are the different types of pattern wheels?

There are several types of pattern wheels, including:

- Spoke wheels: These wheels have a central hub with spokes radiating outward to the rim.

- Disc wheels: These wheels have a solid disc-shaped center with a rim around the outer edge.

- Composite wheels: These wheels are made from a combination of materials, such as carbon fiber and aluminum.

- Tubular wheels: These wheels have a hollow rim made from a lightweight material, such as carbon fiber or aluminum.

2. What are the key factors to consider when choosing a pattern wheel?

Factors to consider when choosing a pattern wheel

- The type of riding you will be doing.

- The weight of the rider and bike.

- The terrain you will be riding on.

- The budget.

Example of how the factors affect the choice of pattern wheel

- If you will be doing mostly road riding, you will want a lightweight wheel with a narrow rim.

- If you will be doing mostly mountain biking, you will want a stronger wheel with a wider rim.

- If you are a heavier rider, you will need a stronger wheel with a wider rim.

- If you are on a budget, you may need to compromise on some of the features you want.

3. What are the common materials used in pattern wheels?

The most common materials used in pattern wheels include:

- Aluminum: Aluminum is a lightweight and durable material that is commonly used in pattern wheels.

- Carbon fiber: Carbon fiber is a strong and lightweight material that is often used in high-end pattern wheels.

- Steel: Steel is a strong and durable material that is often used in budget-friendly pattern wheels.

4. What are the different types of hubs used in pattern wheels?

The most common types of hubs used in pattern wheels include:

- Freehubs: Freehubs allow the wheel to rotate freely when the rider is not pedaling.

- Fixed hubs: Fixed hubs do not allow the wheel to rotate freely when the rider is not pedaling.

- Flip-flop hubs: Flip-flop hubs allow the rider to choose between a freehub and a fixed hub.

5. What are the different spoke patterns used in pattern wheels?

The most common spoke patterns used in pattern wheels include:

- Radial: Each spoke radiates directly from the center of the hub to the rim.

- Tangential: Each spoke is laced to the hub at an angle, tangent to the rim.

- Cross: Each spoke is laced to the hub at an angle and crosses over other spokes.

6. What are the different types of rim profiles used in pattern wheels?

The most common types of rim profiles used in pattern wheels include:

- Box: A box rim has a rectangular cross-section.

- V-shaped: A V-shaped rim has a triangular cross-section.

- Aero: An aero rim has a rounded cross-section.

7. What are the different ways to measure the effectiveness of a pattern wheel?

The effectiveness of a pattern wheel can be measured by a number of factors, including:

- Speed: A faster wheel will allow the rider to travel faster.

- Weight: A lighter wheel will be easier to accelerate and climb hills.

- Durability: A more durable wheel will last longer and require less maintenance.

- Stiffness: A stiffer wheel will be more responsive and less likely to flex under load.

8. What are the latest trends in pattern wheel design?

Some of the latest trends in pattern wheel design include:

- Wider rims: Wider rims are more aerodynamic and can provide better grip on the road.

- Deeper rims: Deeper rims are more aerodynamic and can provide better strength and stiffness.

- Asymmetrical rims: Asymmetrical rims are designed to improve aerodynamics and stiffness.

9. What are the common challenges faced in pattern wheel manufacturing?

Some of the common challenges faced in pattern wheel manufacturing include:

- Ensuring the accuracy of the wheel.

- Balancing the wheel.

- Tensioning the spokes.

10. What are the key quality control checks that need to be performed on pattern wheels?

Some of the key quality control checks that need to be performed on pattern wheels include:

- Checking the accuracy of the wheel.

- Checking the balance of the wheel.

- Checking the tension of the spokes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pattern Wheel Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pattern Wheel Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pattern Wheel Makers are responsible for crafting and maintaining pattern wheels, which are critical components in the production of castings. Their duties encompass a range of tasks related to pattern making, ensuring that wheels meet specifications and contribute to the overall quality of castings.

1. Pattern Making

The primary responsibility of Pattern Wheel Makers lies in the creation and modification of pattern wheels, utilizing various materials such as wood, metal, and plastics. They work closely with engineers and designers to translate blueprints and specifications into tangible patterns.

- Construct pattern wheels based on blueprints and technical drawings

- Select appropriate materials, tools, and equipment for pattern making

- Employ precision measuring and layout techniques to ensure accuracy

- Incorporate design changes and modifications as required

- Maintain and repair existing pattern wheels to extend their lifespan

2. Quality Control

Pattern Wheel Makers are accountable for ensuring the quality of pattern wheels throughout the manufacturing process. They conduct rigorous inspections and tests to verify that wheels meet the desired specifications and industry standards.

- Inspect patterns for dimensional accuracy, surface finish, and overall quality

- Conduct functional testing to assess the performance of patterns

- Identify and resolve any defects or deviations from specifications

- Maintain records and documentation related to quality control procedures

- Collaborate with engineers and designers to improve pattern design and manufacturing processes

3. Shop Floor Support

Pattern Wheel Makers actively support production operations on the shop floor. They provide technical assistance to foundry workers and ensure that patterns are used and maintained properly.

- Troubleshoot and resolve issues related to pattern performance

- Train and guide foundry workers on the correct use and handling of patterns

- Provide technical advice to improve casting quality and efficiency

- Maintain a clean and organized work environment

- Follow safety protocols and regulations

4. Continuous Improvement

Pattern Wheel Makers are committed to continuous improvement and innovation in their field. They actively seek opportunities to enhance their skills, knowledge, and processes.

- Stay abreast of industry best practices and technological advancements

- Participate in training and development programs

- Explore and implement new techniques and materials to improve pattern quality

- Contribute to the development of new products and processes

- Share knowledge and expertise with colleagues

Interview Preparation Tips

To ace the interview for a Pattern Wheel Maker position, it is crucial to be well-prepared and demonstrate a deep understanding of the role’s responsibilities. Here are some key tips to help you excel in the interview:

1. Research the Company and Industry

Gain a thorough understanding of the company’s history, products, and industry standing. Research the latest trends and advancements in pattern making and casting technology. This knowledge will enable you to engage in meaningful conversations and demonstrate your enthusiasm for the field.

- Visit the company’s website, read their annual reports, and follow their social media channels

- Explore industry publications, attend webinars, and connect with professionals in the field

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in pattern making, including your experience with different materials, tools, and techniques. Provide specific examples of your work, demonstrating your ability to create and modify pattern wheels that meet precise specifications. Quantify your accomplishments whenever possible, using metrics to showcase the impact of your contributions.

- Describe the types of patterns you have made, highlighting your experience with complex or challenging designs

- Explain your approach to quality control, including the inspection methods and documentation you use

- Share examples of how you have improved patterns or processes, leading to enhanced casting quality or efficiency

3. Showcase Your Problem-Solving Abilities

Pattern Wheel Makers are often faced with unexpected challenges and must possess strong problem-solving skills. Prepare to discuss situations where you encountered issues with patterns or casting processes and how you identified and resolved them. Highlight your ability to think critically, work independently, and collaborate with others to find solutions.

- Describe a time when you identified a defect in a pattern and developed a solution to correct it

- Explain how you handled a situation where a casting did not meet specifications due to a pattern issue

- Share an example of how you worked with foundry workers to troubleshoot and improve the casting process

4. Emphasize Your Commitment to Quality and Continuous Improvement

Pattern Wheel Makers play a vital role in ensuring the quality of castings. Express your commitment to quality throughout the interview and highlight your attention to detail and dedication to meeting specifications. Additionally, demonstrate your eagerness to learn, grow, and contribute to the company’s continuous improvement efforts.

- Describe your quality control standards and explain how you maintain them in your work

- Share examples of how you have implemented new techniques or materials to improve pattern quality

- Explain your interest in staying up-to-date with industry best practices and advancements

5. Practice Your Communication and Presentation Skills

Effective communication and presentation skills are crucial for Pattern Wheel Makers who need to interact with engineers, designers, and foundry workers. Practice presenting your qualifications and experience clearly and confidently. Prepare examples and stories that demonstrate your technical abilities, problem-solving skills, and commitment to quality.

- Prepare a brief presentation highlighting your key skills and accomplishments

- Practice answering common interview questions, such as “Tell me about your experience in pattern making” or “How do you handle challenges in your work?”

- Be prepared to ask thoughtful questions during the interview, showing your interest in the company and the role

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pattern Wheel Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pattern Wheel Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.