Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pattern Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pattern Worker so you can tailor your answers to impress potential employers.

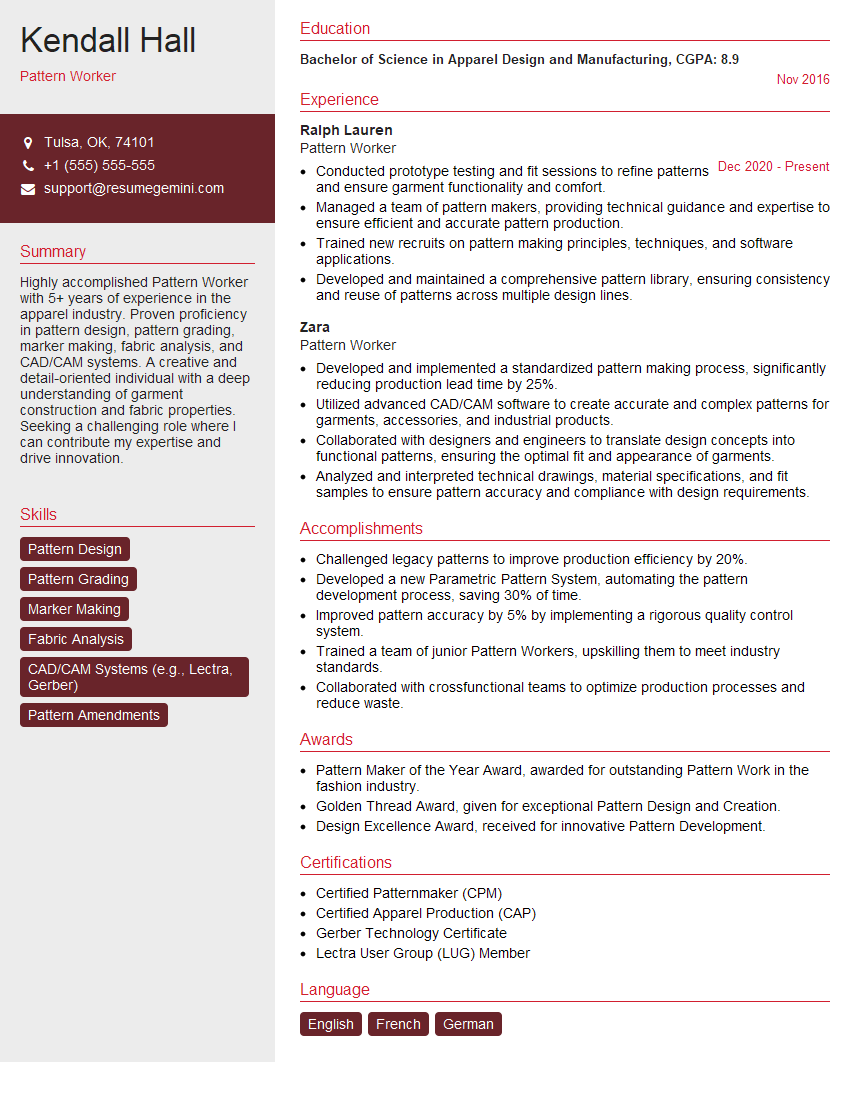

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pattern Worker

1. What are the different types of patterns used in the garment industry?

As a Pattern Worker, I am well-versed in the various types of patterns commonly utilized in the garment industry:

- Basic Patterns: These serve as foundational templates for garment designs and include shapes like bodice blocks, sleeve blocks, and skirt blocks.

- Grading Patterns: Used to modify basic patterns into different sizes while maintaining the garment’s shape and proportions.

- Marker Patterns: Help optimize fabric usage during cutting by efficiently arranging pattern pieces on the fabric layout.

- Prototype Patterns: Created to test the fit and style of a garment design before mass production.

- Production Patterns: Finalized patterns used in mass production to ensure consistency and accuracy in garment construction.

2. Can you explain the process of developing a pattern from scratch?

Sketching and Design

- Begin with a design sketch or inspiration.

- Transfer the design onto paper or a digital platform.

Pattern Creation

- Use pattern making tools and techniques to create the basic pattern.

- Refine and adjust the pattern based on body measurements and design specifications.

Prototyping and Fitting

- Create a prototype garment using the pattern.

- Conduct fittings to assess the fit and make necessary alterations.

Finalization and Grading

- Finalize the pattern based on the fitting results.

- Grade the pattern into different sizes to accommodate a range of body shapes.

3. What are the key factors to consider when grading patterns?

- Growth Allowance: Additional fabric added to patterns to accommodate body growth and movement.

- Ease: The amount of extra fabric added to patterns to provide comfort and freedom of movement.

- Style Lines: Maintaining the integrity of style lines and design details during grading.

- Balance and Symmetry: Ensuring that the pattern pieces remain balanced and symmetrical after grading.

- Fit Specifications: Adhering to industry стандарты for fit and size ranges.

4. How do you ensure accuracy and precision in pattern making?

- Measurement Taking: Using accurate measuring tools and techniques to obtain precise body measurements.

- Pattern Construction: Employing proper pattern making techniques and following established industry guidelines.

- Software Utilization: Utilizing computer-aided design (CAD) software to ensure precision in pattern creation and grading.

- Quality Control: Regularly checking and verifying measurements, pattern pieces, and grading calculations.

- Prototyping and Fitting: Conducting fittings to identify and rectify any errors or inaccuracies in the pattern.

5. Can you describe the role of pattern makers in the garment manufacturing process?

- Design Collaboration: Collaborating with designers to interpret design concepts into wearable patterns.

- Pattern Development: Creating patterns from scratch or modifying existing patterns to meet design specifications.

- Grading and Marker Making: Generating patterns in different sizes and arranging them efficiently on fabric layouts.

- Prototyping and Sampling: Developing prototypes and samples to assess fit and style.

- Production Support: Providing technical guidance and support during garment production to ensure pattern accuracy.

6. What are the challenges faced by pattern makers in the industry?

- Trend Evolution: Keeping up with rapidly changing fashion trends and adapting patterns accordingly.

- Fabric Variation: Working with different fabric types and understanding their properties to ensure patterns are suitable.

- Body Diversity: Catering to a wide range of body shapes and sizes to ensure garments fit well.

- Time Constraints: Meeting tight deadlines while maintaining accuracy and quality in pattern making.

- Technological Advancements: Embracing new technologies and software to enhance efficiency and accuracy.

7. How do you stay updated with the latest trends and developments in pattern making?

- Industry Events: Attending trade shows, workshops, and conferences to learn about new techniques and innovations.

- Online Resources: Utilizing online platforms, forums, and social media to connect with other pattern makers and access up-to-date information.

- Fashion Magazines: Reading fashion magazines and industry publications to stay abreast of current trends and design concepts.

- Continuous Education: Pursuing additional training or courses to enhance skills and knowledge.

- Networking: Building connections with designers, manufacturers, and other professionals in the industry.

8. Can you explain the importance of communication and collaboration in pattern making?

- Effective Communication: Clearly communicating design specifications, pattern modifications, and technical details to ensure accurate pattern execution.

- Collaboration with Designers: Working closely with designers to understand their vision and translate it into workable patterns.

- Teamwork with Manufacturers: Collaborating with manufacturers to provide guidance on pattern interpretation and resolve any production issues.

- Feedback and Iteration: Seeking feedback from colleagues, supervisors, and customers to improve pattern quality and meet expectations.

- Industry Partnerships: Maintaining relationships with suppliers, fabric vendors, and other industry professionals to stay informed and access resources.

9. How do you handle revisions and changes to patterns during the development process?

- Understanding Revisions: Carefully reviewing revision requests to fully comprehend the changes required.

- Impact Assessment: Analyzing the impact of revisions on the pattern, fit, and overall design.

- Pattern Modification: Making precise modifications to the pattern based on the revision specifications.

- Prototyping and Refitting: Creating new prototypes and conducting fittings to ensure the revised patterns meet the desired fit and style.

- Documentation and Communication: Documenting the changes and communicating them effectively to all relevant stakeholders.

10. What are some of the software applications and tools you are proficient in for pattern making?

- Computer-Aided Design (CAD) Software: Using specialized CAD software such as OptiTex, Lectra Modaris, or Gerber AccuMark for pattern creation, grading, and marker making.

- 3D Design Software: Utilizing 3D design software like CLO3D or Marvelous Designer to visualize garment fit and drape.

- Measurement and Grading Tools: Employing digital measurement tools and grading calculators to ensure accuracy and efficiency.

- Collaboration Tools: Utilizing cloud-based platforms and collaboration tools to share patterns, revisions, and feedback with colleagues.

- Industry-Specific Software: Staying updated on industry-specific software and applications to enhance workflow and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pattern Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pattern Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pattern Workers are responsible for creating and maintaining patterns used in the manufacturing of garments and other fabric products. They work closely with designers to ensure that patterns meet specifications and are accurate. Some of their key responsibilities include:1. Pattern Creation

Pattern Workers use computer-aided design (CAD) software or manual techniques to create patterns for garments and other fabric products. They must have a strong understanding of garment construction and fabric properties to ensure that their patterns are accurate and functional.

2. Pattern Grading

Once a pattern has been created, Pattern Workers must grade it to create different sizes. This involves making adjustments to the pattern to ensure that it fits a range of body types. Pattern Workers must have a good eye for detail and be able to make precise measurements.

3. Pattern Marking

Pattern Workers mark patterns with symbols and instructions that guide the cutting and sewing process. These markings must be accurate and easy to understand to ensure that the garments are made correctly.

4. Sample Making

Pattern Workers often make sample garments to test the accuracy of their patterns. This helps to identify any issues with the pattern before it is used for production.

Interview Tips

Before going to interview preparation is very necessary for an interview, as it increases chances of getting success. So, here are the following tips that candidate can follow before going to interview:

1. Research the Company and the Position

It is very necessary to make sure that the candidate is familiar with the company and the position he/she is applying for. It shows that the candidate is interested in the opportunity and has taken the time to learn more about the company.

2. Practice Answering Common Interview Questions

There are several common interview questions that candidates will likely be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

4. Dress Professionally and Arrive on Time

First impression is the last impression, so dressing professionally and arriving on time for the interview is very important. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

5. Be Yourself and Be Confident

It is very necessary to be yourself and be confident during interview. The interviewer can easily notice when someone is being fake. So, being yourself and confident is the best way to make a good impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pattern Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!