Are you gearing up for a career in Paver Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Paver Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

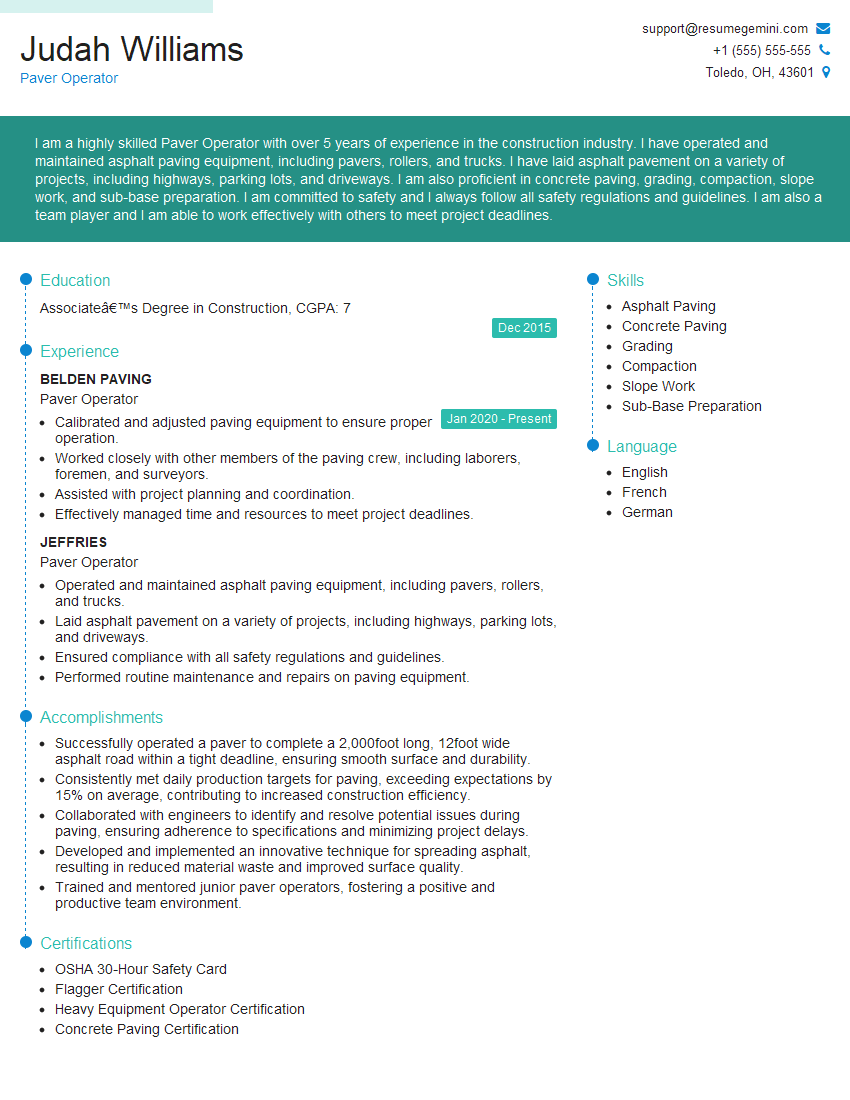

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Paver Operator

1. How do you ensure the correct compaction level of asphalt during paving?

- Conduct compaction tests at regular intervals using a nuclear density gauge or other approved methods.

- Adjust the paver’s speed, vibration settings, and screed angle based on test results to achieve the specified density.

- Monitor the performance of the compaction equipment, including rollers and vibrators, to ensure proper operation.

- Work closely with the paving crew to maintain a consistent paving process and avoid defects.

2. What are the key factors to consider when selecting the proper grade of asphalt for a specific project?

Material composition and type

- Aggregate size, shape, and gradation

- Asphalt binder type and content

- Additives and modifiers

Environmental conditions

- Traffic volume and loads

- Climate and weather conditions

- Underlying soil conditions

Project specifications and requirements

- Design life and performance expectations

- Cost considerations

- Availability and compatibility with existing materials

3. Describe the steps involved in troubleshooting a paver that is leaving streaks or lines in the asphalt surface.

- Inspect the screed plate for wear, damage, or misalignment.

- Check the screed’s vibration settings and ensure they are adjusted correctly.

- Examine the paving hopper and material flow to ensure proper distribution.

- Inspect the paver’s augers and conveyor belts for blockages or damage.

- Confirm that the asphalt mix is properly heated and flowing smoothly.

- Monitor the paving speed and make adjustments as necessary to avoid overworking or undercompacting the material.

4. How do you safely operate a paver in close proximity to obstacles or other equipment?

- Maintain a clear line of sight and be aware of surroundings at all times.

- Use spotters or guides as needed to ensure safe operation.

- Plan the paving route carefully to avoid potential hazards.

- Communicate effectively with other crew members to coordinate movements and prevent accidents.

- Comply with all safety regulations and guidelines.

5. Describe the importance of proper joint preparation and how it affects the overall quality of the pavement.

- Clean and square the edges of existing pavement to ensure a smooth transition.

- Apply tack coat or bonding agent to enhance adhesion between the new and existing materials.

- Lift and replace damaged or deteriorated sections to create a solid base for the new joint.

- Compact the new asphalt along the joint and feather the edges to prevent cracking or separation.

- Proper joint preparation reduces the risk of reflective cracking, water infiltration, and other pavement distresses.

6. How do you handle communication and coordination with the paving crew and other contractors on a paving project?

- Establish clear communication channels and protocols.

- Attend pre-paving meetings and briefings to ensure everyone understands the project plan.

- Use hand signals, radios, or other methods to communicate effectively during paving operations.

- Coordinate with other contractors, such as utility companies, to avoid conflicts or delays.

- Keep the crew informed of potential issues or changes in the paving schedule.

7. What are the common causes of asphalt defects and how can they be prevented?

- Cracking: Caused by thermal stresses, traffic loads, or poor compaction. Prevented by using proper mix design, compaction techniques, and joint preparation.

- Ruts and shoving: Result from excessive traffic loads or weak subgrade. Prevented by ensuring proper asphalt thickness, compaction, and base preparation.

- Bleeding: Excess asphalt binder rises to the surface, creating a slippery or sticky condition. Prevented by using appropriate mix design, avoiding overcompaction, and ensuring proper drainage.

- Corrugation or washboarding: Caused by traffic loads on soft or poorly compacted asphalt. Prevented by using proper compaction techniques, maintaining proper drainage, and avoiding excessive traffic on new asphalt.

8. How do you ensure the proper slope or grade of the asphalt surface during paving?

- Use the paver’s leveling system and grade control sensors.

- Monitor the grade using string lines, stakes, or other leveling devices.

- Make adjustments to the paver’s screed height and screed angle as needed.

- Compact the asphalt properly to maintain the desired slope.

- Check the finished surface with a level or other grading tools to ensure accuracy.

9. What are the key safety precautions to be aware of when operating a paver?

- Wear appropriate safety gear, including hard hat, safety glasses, gloves, and sturdy boots.

- Be aware of pinch points and rotating equipment.

- Keep a safe distance from the paver’s hopper and screed.

- Use caution when working near drop-offs or slopes.

- Communicate clearly with other crew members to avoid accidents.

10. Describe your experience in working with different types of asphalt mixes, such as hot-mix asphalt, cold-mix asphalt, and warm-mix asphalt.

- Hot-mix asphalt: Most common type, heated to high temperatures for placement.

- Cold-mix asphalt: Emulsified asphalt mixed with aggregates, can be placed at ambient temperatures.

- Warm-mix asphalt: Mixes with reduced temperatures, offering environmental and energy benefits.

- Explained the advantages and disadvantages of each type.

- Provided examples of projects where I worked with different mixes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Paver Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Paver Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Paver Operators play a crucial role in road construction and maintenance, ensuring smooth and durable surfaces. Their primary responsibilities encompass:

1. Equipment Operation

Skilled in operating asphalt pavers to lay asphalt on roads, driveways, and other surfaces. Maintaining and calibrating equipment for optimal performance.

- Setting up and adjusting paver controls for desired pavement thickness, width, and slope.

- Operating the paver efficiently to ensure smooth and consistent asphalt application.

2. Material Handling

Coordinating with material delivery trucks to ensure a steady supply of asphalt. Inspecting asphalt quality and temperature to meet project specifications.

- Monitoring asphalt levels in the paver hopper and communicating with the asphalt plant for timely refills.

- Inspecting asphalt for any foreign objects or inconsistencies that may affect pavement quality.

3. Quality Control

Ensuring the quality of the asphalt pavement by monitoring its density, smoothness, and grade. Taking corrective actions as needed to meet project standards.

- Using compaction equipment to achieve specified density requirements.

- Checking pavement smoothness using specialized instruments and making adjustments to the paver accordingly.

4. Site Management

Managing the paver work area, ensuring safety and efficiency. Coordinating with other crews and equipment operators to minimize disruptions.

- Establishing and maintaining clear work zones to prevent accidents.

- Communicating with other operators and crew members to coordinate work schedules and resolve any issues.

Interview Tips

Preparing thoroughly for a Paver Operator interview is crucial to making a positive impression and showcasing your skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the paving industry. Research their projects, company values, and current market trends.

- Visit the company’s website and social media pages to gather information about their operations.

- Stay updated on industry news and advancements in paving technology.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview answers to emphasize your relevant experience and skills. Quantify your accomplishments whenever possible using specific examples.

- Showcase your expertise in operating different types of pavers and equipment.

- Provide examples of projects where you ensured pavement quality and met project specifications.

3. Be Prepared to Discuss Safety

Safety is paramount in paving operations. Prepare to discuss your safety practices and knowledge of industry regulations. Highlight your commitment to maintaining a safe work environment.

- Explain your understanding of proper equipment operation and maintenance procedures.

- Discuss your experience in identifying and mitigating potential hazards on the job site.

4. Show Enthusiasm and a Willingness to Learn

Convey your passion for paving and your eagerness to learn and grow in the industry. Express interest in new technologies and best practices.

- Share examples of how you have stayed up-to-date with industry trends and innovations.

- Ask questions about the company’s training and development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Paver Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!