Are you gearing up for a career in Payloader Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Payloader Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

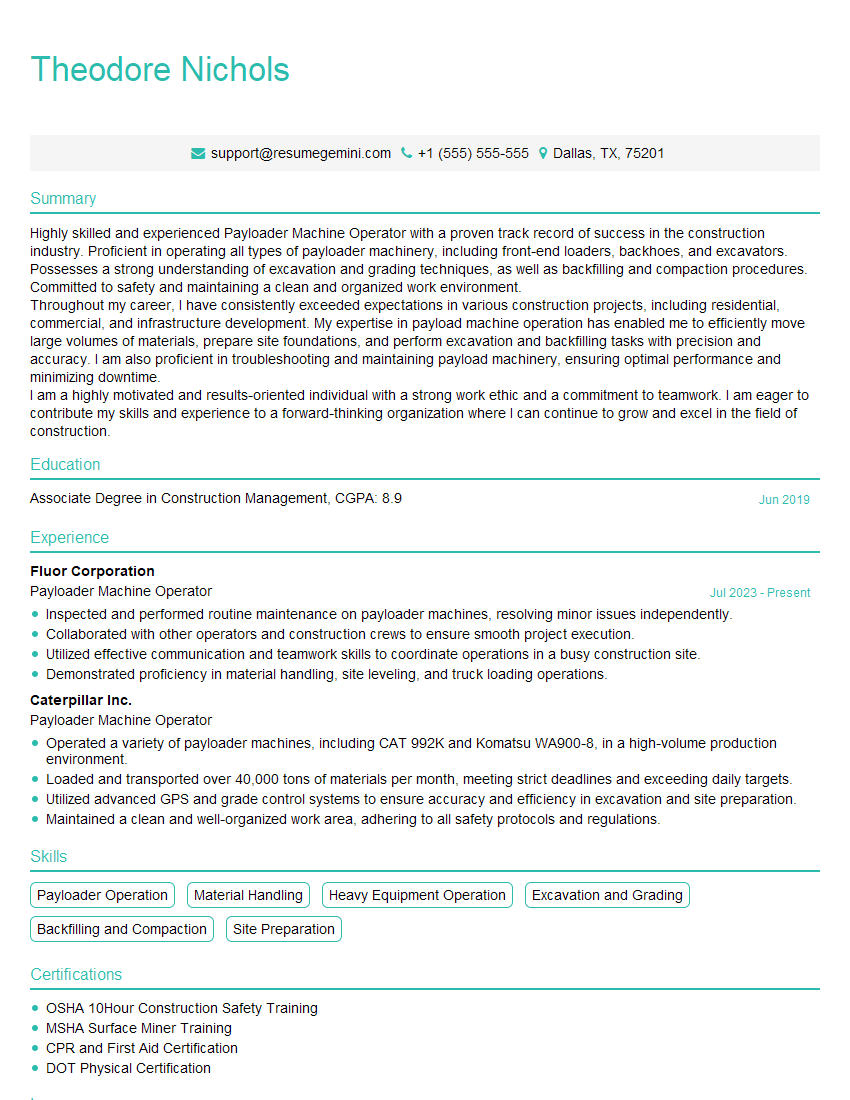

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Payloader Machine Operator

1. What are the key responsibilities of a Payloader Machine Operator?

As a Payloader Machine Operator, my primary responsibilities include:

- Safely and efficiently operating payloader machines to load, unload, and transport materials.

- Monitoring load weights and ensuring proper load distribution to prevent accidents.

- Inspecting and maintaining payloader machines, including daily inspections and minor repairs.

- Communicating effectively with crew members and supervisors to coordinate operations.

- Adhering to all safety regulations and procedures to maintain a safe work environment.

2. Describe the different types of materials you have loaded and unloaded using a payloader.

Common materials:

- Soil

- Sand

- Gravel

- Aggregate

- Construction materials

Specialized materials:

- Hazardous materials

- Oversized loads

- Fragile materials

3. What are the safety precautions you take when operating a payloader machine?

To ensure safety, I always adhere to the following precautions:

- Conduct thorough pre-operational inspections to check machine functionality.

- Wear appropriate personal protective equipment, including hard hat, safety glasses, and gloves.

- Maintain a clear line of sight and reverse direction only when necessary.

- Never exceed the load capacity or travel at unsafe speeds.

- Follow established traffic patterns and communicate intentions clearly.

- Be aware of surroundings and potential hazards, such as overhead wires and uneven terrain.

4. How do you ensure the accuracy of load weights when using a payloader?

To guarantee load accuracy, I employ the following measures:

- Regularly calibrate the payloader’s weighing system.

- Check the load against known weights or use a weighbridge when available.

- Estimate load weights based on material density and volume.

- Monitor load distribution to prevent overloading or instability.

5. Describe a situation where you had to troubleshoot a problem with a payloader machine.

Once, the payloader’s hydraulic system malfunctioned, causing the bucket to lower uncontrollably. I quickly:

- Shut down the engine.

- Checked the hydraulic fluid levels and hoses for leaks or damage.

- Isolated the faulty component by testing each valve and cylinder.

- Replaced the defective valve, which resolved the issue.

6. How do you maintain and inspect a payloader machine to ensure its optimal performance?

I follow a comprehensive maintenance schedule that includes:

- Daily inspections of fluid levels, filters, and tires.

- Weekly greasing and lubrication of moving parts.

- Monthly inspections of hydraulic systems, brakes, and electrical components.

- Regular maintenance of bucket attachments and other accessories.

- Prompt reporting of any issues or potential problems.

7. What are the different types of attachments you have used on a payloader, and for what purposes?

- Buckets: For loading and unloading various materials.

- Forks: For handling pallets and other objects.

- Grapples: For grasping and moving heavy objects or debris.

- Snow blades: For clearing snow and other debris.

8. How do you handle working in challenging conditions, such as rain, snow, or extreme temperatures?

I adapt to challenging conditions by:

- Adjusting driving speed and using caution on slippery or uneven surfaces.

- Clearing snow or ice from the payloader before operation.

- Taking breaks to warm up or cool down in extreme temperatures.

- Wearing appropriate clothing and gear for the weather conditions.

9. How do you manage multiple tasks and prioritize your workload when operating a payloader?

To effectively manage multiple tasks, I:

- Create a clear plan and prioritize tasks based on urgency and importance.

- Delegate responsibilities to other crew members when possible.

- Communicate regularly with supervisors and colleagues to coordinate efforts.

- Stay organized and maintain a clean work area.

10. What is your understanding of the importance of teamwork in the operation of a payloader machine?

Teamwork is crucial in payloader operations for:

- Ensuring safety and preventing accidents through effective communication.

- Coordinating movements and avoiding collisions when working in close proximity with other machines or personnel.

- Troubleshooting and problem-solving by sharing knowledge and expertise.

- Maintaining a positive and efficient work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Payloader Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Payloader Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Payloader Machine Operator plays a crucial role in various construction and mining projects, handling a wide range of tasks and ensuring efficient operations. Their primary responsibilities include:

1. Machine Operation and Maintenance

Skilled operation of payloader machines, adhering to safety regulations and guidelines.

- Loading and unloading materials, such as soil, gravel, and debris, with precision and accuracy.

- Maintaining proper machine functionality through regular inspections, minor repairs, and lubrication.

2. Site Management and Coordination

Coordinating with other crew members and equipment operators to ensure smooth project flow.

- Planning and executing excavation and grading activities based on project specifications.

- Communicating effectively with supervisors and colleagues to optimize site logistics.

3. Safety Compliance and Environmental Awareness

Prioritizing safety on the job site and following established protocols.

- Wearing appropriate personal protective equipment (PPE) and adhering to safety regulations.

- Maintaining a clean and organized work area to minimize hazards and potential accidents.

4. Performance Monitoring and Reporting

Monitoring machine performance and reporting any issues or maintenance needs promptly.

- Tracking daily progress and providing updates to supervisors as required.

- Documenting any operational challenges or suggestions for improvement.

Interview Tips

Preparing thoroughly for a Payloader Machine Operator interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company, its industry, and the specific role you’re applying for.

- Visit the company’s website to gather information about their operations, values, and recent projects.

- Read industry news and articles to stay updated on the latest trends and best practices.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements.

- Quantify your accomplishments whenever possible. For instance, instead of saying “I operated a payloader,” you could say, “I operated a payloader and increased productivity by 15%.”

- Prepare examples of your problem-solving abilities and how you’ve handled challenges on previous projects.

3. Demonstrate Safety Consciousness

Safety is paramount in the construction industry. Highlight your commitment to safety.

- Discuss your knowledge of safety regulations and your adherence to proper safety protocols.

- Share examples of how you’ve identified and mitigated potential hazards on the job site.

4. Practice Common Interview Questions

Prepare for common interview questions to improve your confidence and articulation.

- Practice answering questions about your experience, skills, and why you’re interested in the position.

- Prepare questions to ask the interviewer to demonstrate your enthusiasm and engagement.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving on time for your interview.

- Wear clean, pressed clothing that is appropriate for an industrial setting.

- Arrive at the interview location a few minutes early to show respect for the interviewers’ time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Payloader Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!