Are you gearing up for an interview for a Peanut Butter Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Peanut Butter Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

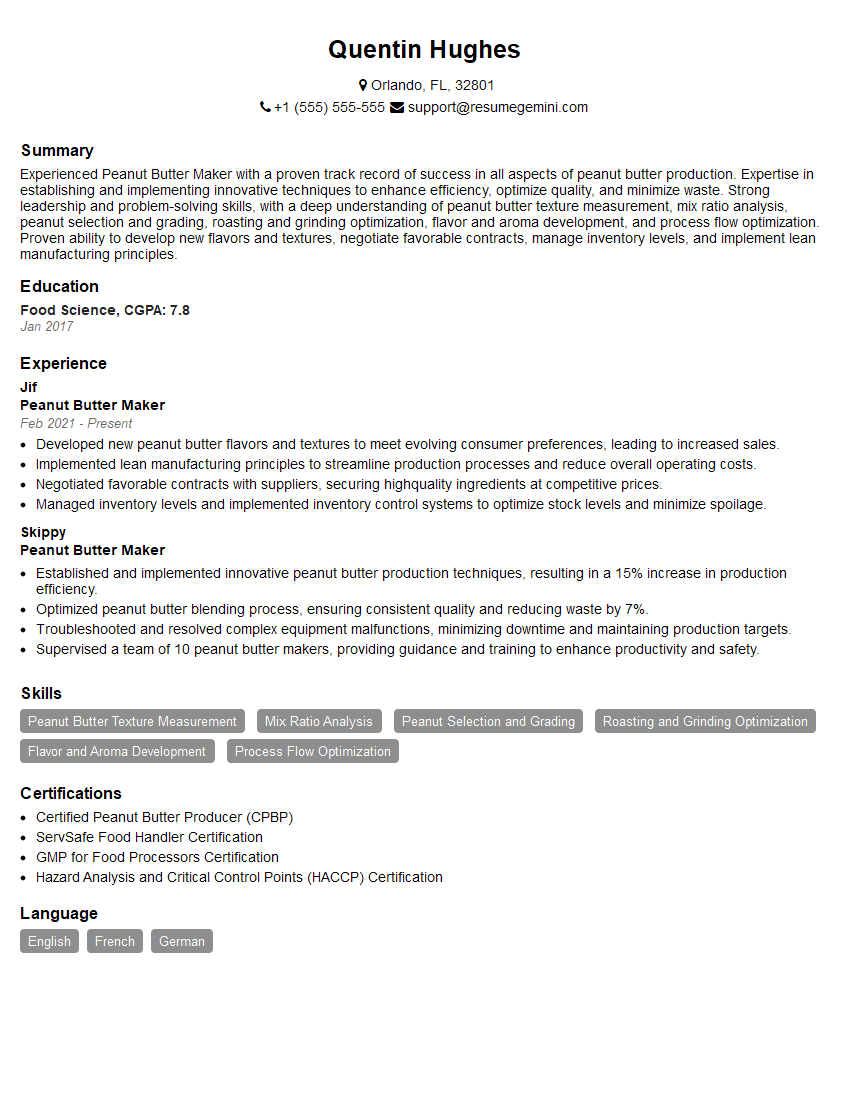

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Peanut Butter Maker

1. What are the key raw materials used in peanut butter production?

The key raw materials used in peanut butter production are:

- Peanuts

- Oil (usually hydrogenated vegetable oil)

- Salt

- Sugar (optional)

- Stabilizers (optional)

2. Describe the process of roasting peanuts for peanut butter production.

The process of roasting peanuts for peanut butter production involves the following steps:

- Cleaning: Peanuts are cleaned to remove any dirt, debris, or foreign objects.

- Sorting: Peanuts are sorted by size and quality to ensure uniformity in roasting.

- Roasting: Peanuts are roasted in ovens or roasters at high temperatures (325-350°F) for a specific duration to enhance their flavor and aroma.

- Cooling: Roasted peanuts are cooled rapidly to prevent overcooking and preserve their texture.

3. What are the different types of peanut butter grinders used in production?

- Stone grinders: These grinders use two large stones to crush and grind peanuts, producing a smooth and creamy texture.

- Blade grinders: These grinders use rotating blades to cut and grind peanuts, resulting in a more chunky texture.

- Colloid mills: These grinders use a high-speed rotor and stator to shear and grind peanuts, producing a very fine and smooth texture.

4. Explain the importance of temperature control during peanut butter production.

- Roasting: Temperature control during roasting is crucial to develop the desired flavor and aroma of peanuts.

- Grinding: Temperature control during grinding prevents the peanut butter from overheating and becoming grainy or oily.

- Storage: Peanut butter should be stored at the proper temperature to maintain its quality and prevent spoilage.

5. What are the common defects that can occur in peanut butter production and how are they prevented?

- Grainy texture: This can be prevented by optimizing the grinding process and using high-quality peanuts.

- Oily separation: This can be prevented by using the correct ratio of oil to peanuts and ensuring proper mixing.

- Rancidity: This can be prevented by using fresh peanuts, controlling storage temperature, and adding antioxidants.

- Mold growth: This can be prevented by maintaining proper hygiene and using preservatives.

6. Describe the quality control measures implemented in peanut butter production.

- Raw material inspection: Peanuts are inspected for quality and cleanliness before being used in production.

- Process monitoring: Temperature, grinding time, and other process parameters are monitored to ensure consistency.

- Finished product testing: Peanut butter is tested for texture, taste, color, and other quality attributes.

- Packaging and storage: Peanut butter is packaged and stored under controlled conditions to maintain its quality.

7. What are the latest trends and innovations in peanut butter production?

- Use of alternative sweeteners: Peanut butter manufacturers are exploring natural sweeteners, such as honey or maple syrup, to reduce sugar content.

- Plant-based peanut butter: Peanut butter made from plant-based proteins, such as chickpeas or almonds, is gaining popularity.

- Automated production lines: Peanut butter production is becoming increasingly automated to improve efficiency and reduce labor costs.

- Sustainability initiatives: Peanut butter manufacturers are implementing sustainable practices, such as reducing waste and using renewable energy.

8. Describe the role of packaging in peanut butter production.

- Protects the product: Packaging protects peanut butter from light, moisture, and oxygen, extending its shelf life.

- Provides information: Packaging provides consumers with important information about the product, such as ingredients, nutritional value, and storage instructions.

- Marketing and branding: Packaging can be used to differentiate products and build brand recognition.

9. What are the key safety considerations in peanut butter production?

- Peanut allergies: Peanuts are a common allergen, so manufacturers must implement strict measures to prevent cross-contamination.

- Food safety hazards: Peanut butter production facilities must adhere to food safety regulations to prevent contamination with bacteria or microorganisms.

- Equipment safety: Peanut butter production equipment must be operated and maintained safely to prevent accidents.

10. How do you stay up-to-date on the latest technologies and best practices in peanut butter production?

- Attend industry conferences and workshops.

- Read trade publications and research journals.

- Network with other peanut butter manufacturers.

- Explore online resources and webinars.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Peanut Butter Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Peanut Butter Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Peanut Butter Maker is responsible for the production of peanut butter in a food manufacturing facility. They operate and maintain equipment, ensure product quality, and adhere to safety and sanitation standards.

1. Production and Operation

The Peanut Butter Maker is responsible for the smooth operation of the production line. They:

- Operate and monitor equipment used in peanut butter production, including roasters, grinders, and packaging machines.

- Adjust and maintain equipment as needed to ensure optimal performance and product quality.

- Follow established production procedures and recipes to ensure consistent product quality.

- Monitor production output and make necessary adjustments to meet production targets.

2. Quality Assurance

The Peanut Butter Maker is responsible for ensuring the quality of the peanut butter produced. They:

- Inspect raw materials and finished products to ensure they meet quality standards.

- Conduct quality control tests to monitor product consistency, flavor, and texture.

- Identify and address any quality issues promptly to prevent defective products from reaching consumers.

3. Sanitation and Safety

The Peanut Butter Maker is responsible for maintaining a clean and safe work environment. They:

- Adhere to established sanitation and safety protocols to prevent contamination and accidents.

- Clean and sanitize equipment and work areas regularly.

- Follow proper handling and disposal procedures for hazardous materials.

- Wear appropriate personal protective equipment (PPE) while operating equipment and handling materials.

4. Troubleshooting and Maintenance

The Peanut Butter Maker is responsible for troubleshooting and resolving production issues. They:

- Identify and diagnose malfunctions in equipment.

- Perform basic maintenance and repairs to ensure equipment is operating efficiently.

- Collaborate with maintenance technicians to resolve complex issues.

- Keep records of maintenance and repairs performed.

Interview Tips

Preparing for an interview for a Peanut Butter Maker position is essential to showcase your qualifications and land the job. Here are some interview tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific Peanut Butter Maker position. This will give you a better understanding of their operations, values, and the role you will be expected to play. Learn about the company’s history, mission, and products. Identify the key responsibilities of the Peanut Butter Maker position and how your skills and experience align with them.

2. Practice Common Interview Questions

Practice answering common interview questions related to your skills, experience, and qualifications. Anticipate questions about your knowledge of peanut butter production, quality control, and safety procedures. Prepare thoughtful and concise answers that highlight your strengths and abilities. Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your work experience.

- Example: “Tell me about a time you identified and resolved a production issue.” Response: “In my previous role, I encountered a situation where a packaging machine was malfunctioning and causing production delays. I diagnosed the issue as a faulty sensor and promptly replaced it, restoring the machine to optimal performance, reducing downtime, and meeting production targets.”

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that make you a suitable candidate for the Peanut Butter Maker position. Highlight your knowledge of peanut butter production processes, quality control techniques, and sanitation practices. Showcase your ability to operate and maintain equipment, troubleshoot issues, and ensure product quality.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the position and the company. It also allows you to gain additional insights into the role and the organization. Ask questions about the company’s growth plans, sustainability initiatives, or any specific challenges the Peanut Butter Maker may face.

- Example: “What are the company’s goals for expanding its peanut butter product line in the future?”

5. Dress Professionally and Arrive on Time

Make a positive impression by dressing professionally and arriving on time for your interview. First impressions matter, so ensure you are well-groomed and wear appropriate business attire. Punctuality shows respect for the interviewer’s time and demonstrates your professionalism.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Peanut Butter Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.