Feeling lost in a sea of interview questions? Landed that dream interview for Pearl Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pearl Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

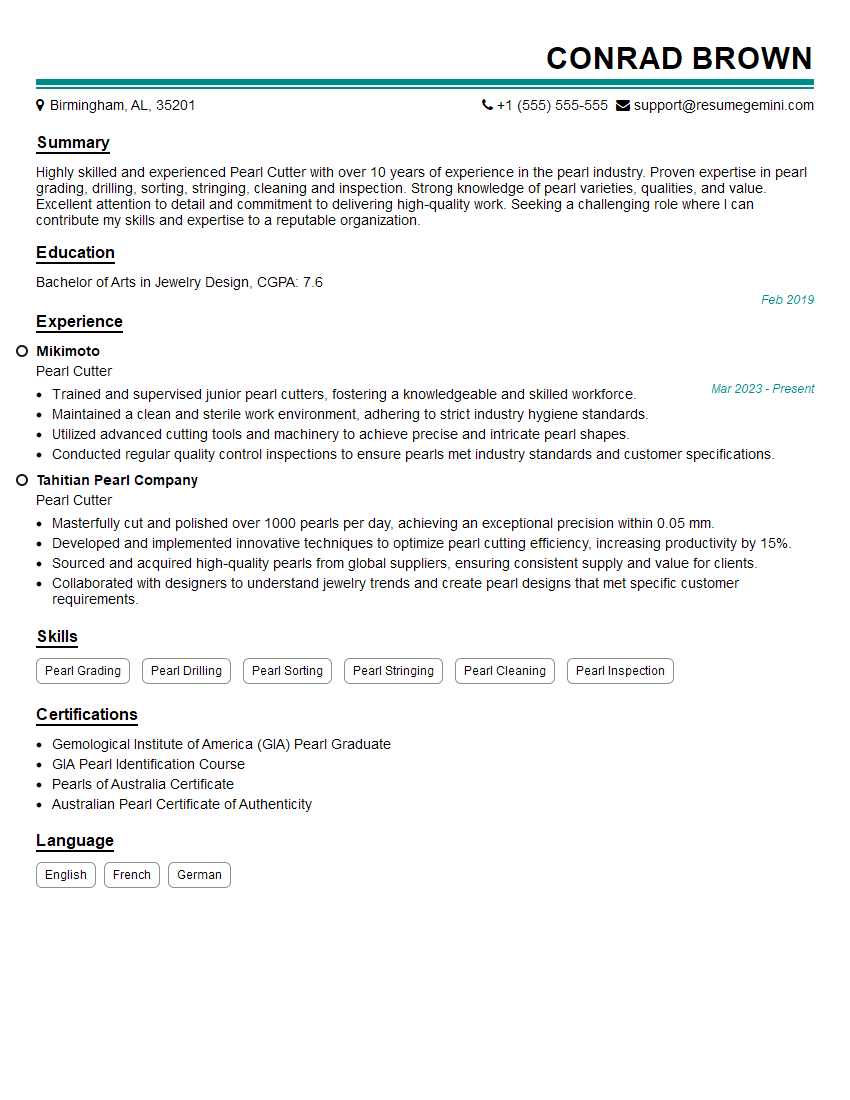

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pearl Cutter

1. Explain the different types of pearls and their characteristics?

There are various types of pearls, each with unique characteristics:

- Akoya Pearls: Known for their round shape, white or cream color, and high luster.

- South Sea Pearls: Famous for their large size, silvery-white or golden color, and intense luster.

- Tahitian Pearls: Distinctive for their dark, peacock-like colors ranging from gray to black.

- Freshwater Pearls: Irregularly shaped, often baroque, and available in a wide range of colors.

- Keshi Pearls: Natural, non-nucleated pearls with a unique, non-spherical shape.

2. What factors affect the value of a pearl?

Size and Shape:

- Larger pearls are generally more valuable.

- Round or near-round pearls command a premium.

Color and Luster:

- Rare or highly desirable colors, such as black or golden, increase value.

- Pearls with high luster, reflecting light evenly, are more valuable.

Surface Quality:

- Pearls with few surface blemishes or imperfections are more valuable.

Matching and Origin:

- Matching pearls, especially in large quantities, enhance value.

- Pearls from certain regions, such as the South Seas, are more prized.

3. Describe the process of pearl cultivation?

Pearl cultivation involves the following steps:

- Nucleation: A small bead or piece of tissue is inserted into the oyster’s gonad.

- Implantation: The oyster encapsulates the nucleus with layers of nacre, forming the pearl.

- Growth: The oyster secretes nacre over several years, gradually increasing the pearl’s size.

- Harvesting: Once the desired size and quality are reached, the pearls are surgically removed.

4. Explain the difference between natural and cultured pearls?

- Natural Pearls: Formed naturally in wild oysters without human intervention, extremely rare and valuable.

- Cultured Pearls: Produced through pearl cultivation techniques, where a nucleus is inserted into an oyster, resulting in a more controlled and consistent product.

5. What are the different cutting techniques used for pearls?

- Round Cutting: Creates a spherical or near-spherical shape, used for classic designs.

- Baroque Cutting: Preserves the natural, irregular shape of the pearl, resulting in unique and artistic pieces.

- Fancy Cutting: Involves shaping the pearl into various non-traditional shapes, such as ovals, squares, or hearts.

6. How do you determine the quality of a cut pearl?

- Symmetry: The pearl should be evenly shaped, with a consistent outline.

- Surface Finish: The pearl should have a smooth and lustrous surface, free from visible blemishes.

- Matching: If the pearl is part of a set, the pearls should match in size, shape, and color.

7. What are the challenges and considerations when cutting pearls?

- Fragility: Pearls are delicate and can easily crack or chip if handled improperly.

- Determining Shape: Deciding the optimal cut to enhance the pearl’s natural beauty and value.

- Balancing Precision and Preservation: Achieving the desired shape while preserving the pearl’s structural integrity.

8. What tools and equipment are used for pearl cutting?

- Pearl Cutter: A specialized tool with fine, diamond-tipped blades for precise cutting.

- Magnifying Glass or Microscope: Aids in examining the pearl’s surface and guiding the cutting process.

- Water: Used as a lubricant to keep the cutting area cool and prevent overheating.

- Micrometer: Measures the pearl’s size and ensures accuracy in cutting.

9. How do you ensure the safety of pearls during the cutting process?

- Proper Handling: Using appropriate tools and techniques to avoid damaging the pearl.

- Controlled Environment: Maintaining a clean and humid environment to prevent cracks or drying.

- Regular Inspection: Monitoring the pearl’s condition throughout the cutting process.

- Adequate Lighting: Illuminating the cutting area to enhance visibility and precision.

10. Describe your approach to cutting a high-value pearl?

- Thorough Examination: Carefully inspecting the pearl’s size, shape, and surface characteristics.

- Planning: Determining the optimal cut to maximize the pearl’s beauty and value.

- Precision Cutting: Using specialized tools and techniques to execute the cut with accuracy and care.

- Post-Cutting Inspection: Verifying the cut’s quality, smoothness, and symmetry.

- Protection: Handling the pearl with utmost care to prevent damage or scratches.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pearl Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pearl Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pearl Cutting is an art in itself, and Pearl Cutters are responsible for transforming raw pearls into beautiful and valuable pieces. The key job responsibilities of a Pearl Cutter include:

1. Pearl Selection and Inspection

The first step in pearl cutting is selecting the right pearls. Pearl Cutters must inspect the pearls for their size, shape, color, and quality. They must also determine the best way to cut the pearl to maximize its beauty and value.

2. Pearl Cutting

Once the pearls have been selected, Pearl Cutters use a variety of tools to cut them. The most common cutting methods are sawing, drilling, and grinding. Pearl Cutters must be skilled in using these tools to create precise cuts.

3. Pearl Polishing

After the pearls have been cut, they must be polished to give them a smooth and lustrous finish. Pearl Cutters use a variety of polishing tools to achieve the desired results.

4. Pearl Grading

Once the pearls have been cut and polished, they must be graded. Pearl Cutters use a variety of criteria to grade pearls, including size, shape, color, and luster. The grade of a pearl will determine its value.

Interview Tips

Preparing for a pearl cutter interview can be challenging, but there are a few tips that can help you ace the interview. Here are some tips to help you prepare:

1. Research the company and the position

Before you go to an interview, it is important to do your research. Learn about the company and the specific position you are applying for. This will help you answer questions about the company and the position in a knowledgeable and enthusiastic way.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked in a pearl cutter interview. Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Bring a portfolio of your work

If you have a portfolio of your pearl cutting work, bring it to the interview. This will give the interviewer a chance to see your skills and experience firsthand.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

5. Be confident and enthusiastic

Confidence and enthusiasm are key in any interview, but they are especially important in a pearl cutter interview. Pearl cutting is a challenging and rewarding profession, so you need to be able to convey your passion for the work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pearl Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!