Are you gearing up for an interview for a Pecan Huller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pecan Huller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

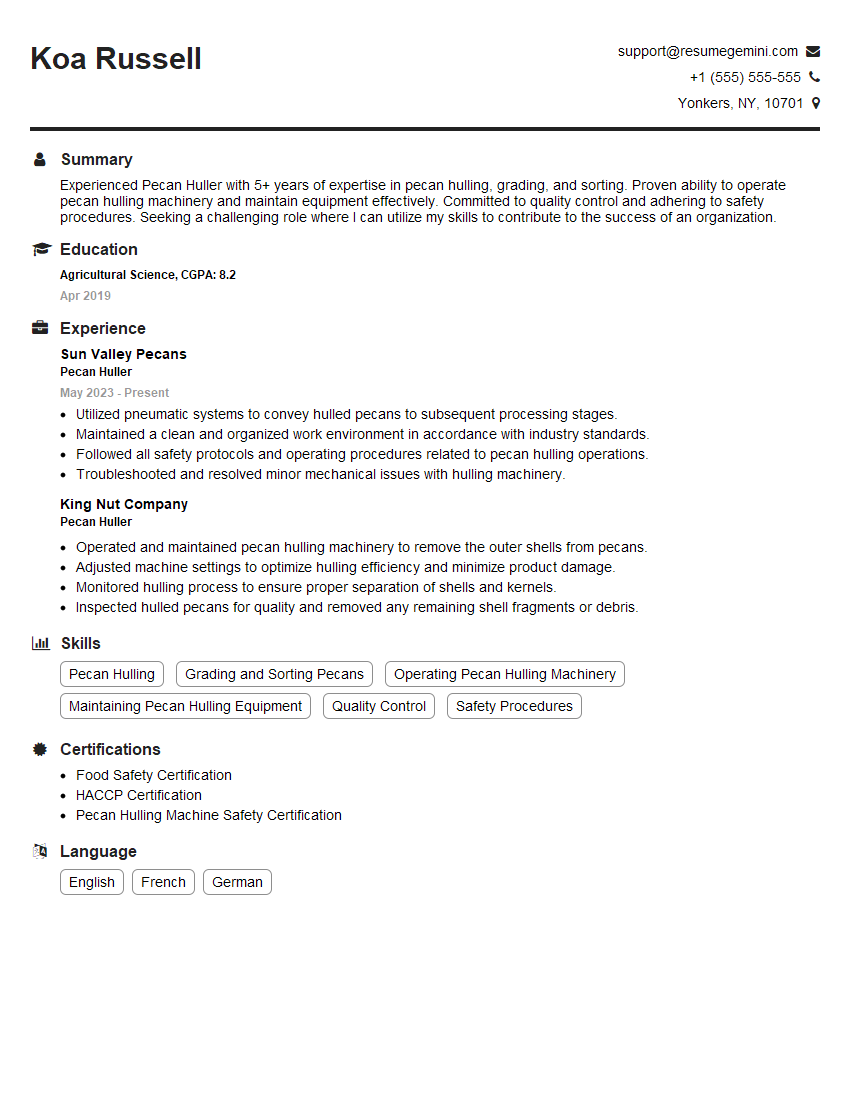

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pecan Huller

1. Explain the basic principles involved in pecan hulling?

The basic principles of pecan hulling involves the following steps:

- Gathering pecans: Pecans are collected from pecan trees, either by hand-picking or using mechanical harvesters.

- Removing debris: Any debris, such as leaves, twigs, and dirt, is removed from the pecans.

- Hulling: The pecans are then passed through a hulling machine, which removes the outer hulls.

- Drying: The hulled pecans are dried to reduce their moisture content and make them easier to store.

- Packaging: The dried pecans are packaged in various containers, such as bags or boxes, for distribution.

2. What types of pecan hulling machines are commonly used and how do they work?

Mechanical Hullers:

- Use rotating blades or rollers to break the hulls without damaging the kernels.

- May be automated or manually operated.

Chemical Hullers:

- Involve soaking pecans in a chemical solution to dissolve the hulls.

- Less common due to concerns about chemical residues.

3. Describe the process of calibrating a pecan hulling machine to ensure optimal efficiency.

Calibrating a pecan hulling machine involves adjusting various settings to optimize performance:

- Roll Gap: Adjusting the gap between the rotating rollers to ensure the hulls are removed without damaging the kernels.

- Roller Speed: Setting the speed of the rollers to optimize hull removal while minimizing kernel damage.

- Airflow: Adjusting the airflow system to remove loose hulls and minimize kernel loss.

- Moisture Content: Fine-tuning the moisture content of the pecans to facilitate efficient hull removal.

4. Explain the importance of maintaining proper moisture content in pecan hulls during processing.

- Efficient Hull Removal: Optimal moisture content allows the hulls to be easily removed without sticking to the kernels.

- Kernel Quality: Excessive moisture can lead to mold and kernel damage, while insufficient moisture can make hulling difficult.

- Product Shelf Life: Maintaining proper moisture content contributes to the shelf life and quality of the hulled pecans.

5. Describe the safety protocols and regulations that must be followed when operating pecan hulling machinery.

- Machine Guarding: Ensuring that all moving parts are properly guarded to prevent contact with workers.

- Electrical Safety: Following electrical safety procedures, such as grounding equipment and using lockout/tagout devices.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as gloves, earplugs, and safety glasses.

- Machine Operation: Receiving proper training on machine operation and following manufacturer’s guidelines.

6. Explain the quality control procedures used to ensure the quality of hulled pecans.

- Visual Inspection: Inspecting pecans for defects, such as cracks, damage, or discoloration.

- Moisture Testing: Measuring the moisture content of pecans to ensure it meets specifications.

- Kernel Analysis: Evaluating the appearance, texture, and flavor of pecan kernels.

- Sampling and Testing: Taking representative samples for laboratory testing to assess overall quality and safety.

7. Describe the maintenance procedures required to keep pecan hulling machines operating smoothly.

- Regular Cleaning: Removing debris and dust from the machine to prevent blockages.

- Roller Adjustment: Periodically adjusting the roll gap to maintain optimal hull removal.

- Lubrication: Greasing and oiling moving parts to ensure smooth operation.

- Inspection: Regularly inspecting the machine for wear or damage and addressing any issues promptly.

8. How do you troubleshoot common problems that may arise during pecan hulling?

- Difficulty Removing Hulls: Adjust roll gap, increase roller speed, or check airflow.

- Kernel Damage: Reduce roller speed, adjust roll gap, or inspect for foreign objects.

- Excessive Hull Loss: Decrease roller speed, adjust airflow, or check for worn rollers.

- Machine Blockages: Clean the machine thoroughly and check for any obstructions.

9. Explain your experience in working with other pecan hulling operators and maintaining a collaborative work environment.

- Describe instances of working effectively with colleagues to achieve common goals.

- Highlight your communication and teamwork abilities.

- Emphasize your commitment to a positive and productive work environment.

10. How do you stay up-to-date on the latest advances in pecan hulling technology?

- Attending industry conferences and workshops.

- Reading trade publications and online articles.

- Consulting with equipment manufacturers and industry experts.

- Participating in continuing education programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pecan Huller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pecan Huller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pecans are a type of tree nut that is grown in warm climates. Pecan Hullers are responsible for the process of removing the outer husk or hull from the pecan. This process is necessary to get the pecans ready for sale and consumption. Pecan hullers typically work in a factory setting, and they use a variety of machines to remove the hulls from the pecans.

1. Operating Pecan Hulling Machine

A pecan hulling machine is a large piece of equipment that uses a combination of rotating brushes and suction to remove the hulls from pecans. The operator of the machine must be able to feed the pecans into the machine correctly and monitor the machine to ensure that the pecans are being hulled properly.

- Loading pecans into the hulling machine

- Starting and stopping the machine

- Monitoring the machine to ensure that the pecans are being hulled properly

2. Inspecting Pecans

Once the pecans have been hulled, they must be inspected to ensure that they are free of any remaining hulls or debris. The inspector must also check the pecans for any signs of damage or defects.

- Visually inspecting pecans for any remaining hulls or debris

- Checking pecans for any signs of damage or defects

- Sorting pecans into different grades based on their quality

3. Packaging Pecans

Once the pecans have been inspected, they must be packaged for sale. The packager must be able to weigh and package the pecans correctly and label the packages with the correct information.

- Weighing and packaging pecans

- Labeling packages with the correct information

- Loading packages onto pallets

4. Maintaining Equipment

The pecan huller must be able to maintain the equipment used to hull and inspect the pecans. This includes cleaning the machines, changing filters, and making minor repairs.

- Cleaning the machines

- Changing filters

- Making minor repairs

- Lubricating moving parts

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your pecan huller interview:

1. Research the Company

Before you go to your interview, take some time to research the company you are interviewing with. This will help you understand the company’s culture and values, and it will also give you a better idea of the type of work you will be doing.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Write down a list of questions that you think you might be asked

- Practice answering these questions out loud

- Get feedback from a friend or family member

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing excessive jewelry or perfume.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing excessive jewelry or perfume

4. Be Punctual

Punctuality is important for any interview, but it is especially important for a pecan huller interview. This job requires you to be able to work independently and meet deadlines, so being on time for your interview will show the employer that you are reliable and responsible.

- Plan your route to the interview in advance

- Give yourself plenty of time to get there

- If you are running late, call the employer to let them know

5. Be Enthusiastic

The pecan huller job can be physically demanding, so it is important to show the employer that you are enthusiastic about the work. This means being positive and upbeat during your interview, and it also means being willing to work hard.

- Smile and make eye contact with the interviewer

- Be positive and enthusiastic about the job

- Show the interviewer that you are willing to work hard

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pecan Huller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!