Feeling lost in a sea of interview questions? Landed that dream interview for Pellet Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pellet Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

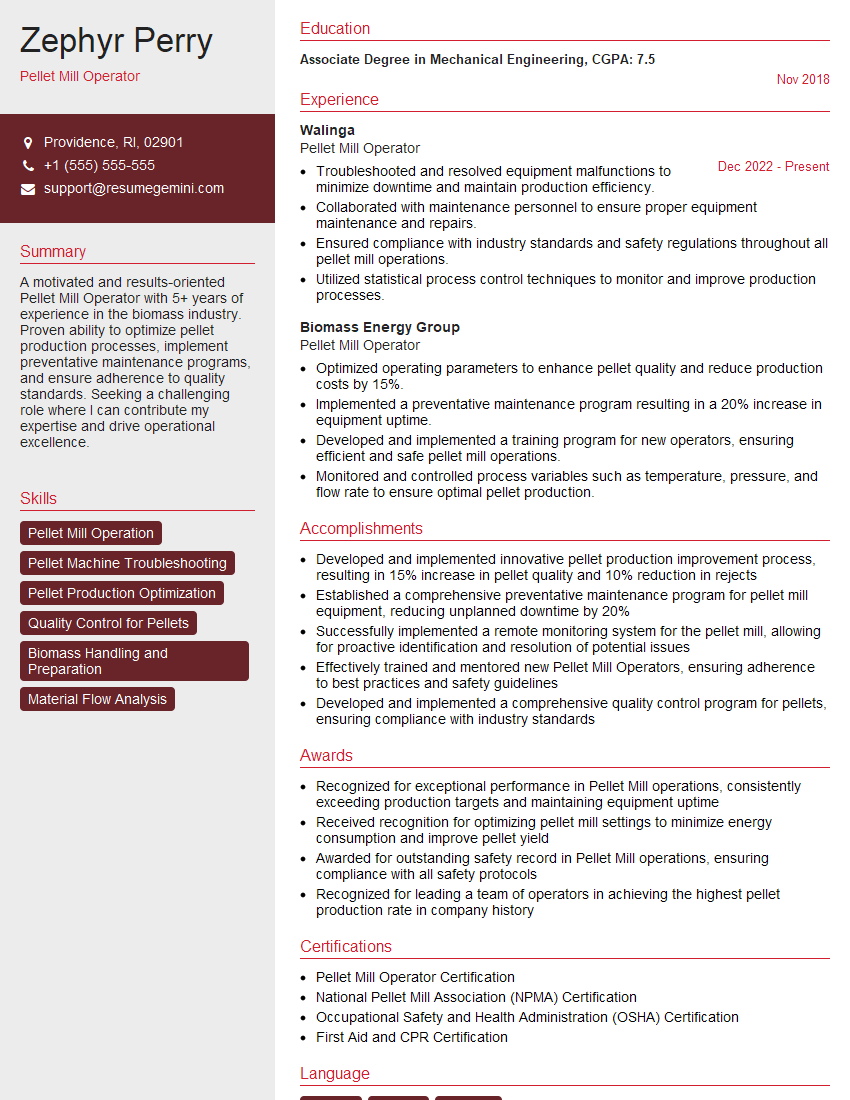

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pellet Mill Operator

1. Describe the process of pellet production in a pellet mill?

In pellet production, the process begins with raw materials such as wood chips, sawdust, or agricultural residues being fed into the mill. These materials are then ground into a fine powder using grinders or hammer mills.

The powdered material is then conveyed to the pellet mill, where it is forced through a die under high pressure. The die has holes of a specific size and shape, which determines the size and shape of the pellets. As the material is forced through the die, it is heated and compressed, causing it to bind together and form pellets.

The pellets are then cooled and screened to remove any fines or oversize particles. They are then ready to be used as fuel, animal feed, or other applications.

2. What are the key factors that affect pellet quality?

Raw materials

- The type and quality of raw materials used can significantly impact the quality of the finished pellets.

- Factors such as moisture content, particle size, and density can all affect the pelletizing process and the quality of the pellets produced.

Pellet mill equipment

- The type of pellet mill equipment used can also affect pellet quality.

- Factors such as the size and shape of the die, the pressure applied, and the temperature of the process can all impact the quality of the pellets produced.

Process parameters

- The process parameters used during pelleting can also affect the quality of the finished pellets.

- Factors such as the feed rate, the moisture content of the material, and the temperature of the process can all impact the quality of the pellets produced.

3. How do you maintain and troubleshoot a pellet mill?

Regular maintenance is essential to keep a pellet mill operating efficiently and producing high-quality pellets.

- Regularly inspect the mill for wear and tear, and replace worn parts as needed.

- Clean the mill regularly to remove any buildup of material, which can reduce efficiency and damage the mill.

- Lubricate the mill according to the manufacturer’s recommendations.

If a pellet mill is not operating properly, there are a few common troubleshooting steps that can be taken:

- Check the raw materials to ensure they are of good quality and meet the specifications of the mill.

- Inspect the mill for any wear or damage and replace worn parts as needed.

- Check the process parameters to ensure they are set correctly.

- If the problem persists, contact the manufacturer of the mill for assistance.

4. What are the safety precautions that should be taken when operating a pellet mill?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Never operate a pellet mill without proper training.

- Keep the mill area clean and free of debris.

- Never reach into the mill while it is operating.

- Be aware of the moving parts of the mill and keep your hands and other body parts away from them.

- Never attempt to repair the mill while it is operating.

- Always follow the manufacturer’s instructions for operating and maintaining the mill.

5. What are the environmental considerations associated with pellet production?

- Pellet production can generate air pollution, water pollution, and solid waste.

- Air pollution can be caused by the release of particulate matter, volatile organic compounds (VOCs), and other pollutants from the mill.

- Water pollution can be caused by the discharge of wastewater from the mill, which can contain suspended solids, nutrients, and other pollutants.

- Solid waste can be generated from the disposal of spent pellets, which can contain heavy metals and other contaminants.

There are a number of ways to reduce the environmental impact of pellet production, including:

- Using sustainable raw materials, such as wood from sustainably managed forests.

- Using energy-efficient pellet mills.

- Installing pollution control equipment to reduce air and water pollution.

- Recycling spent pellets to reduce solid waste.

6. What are the different types of pellet mills available?

- There are two main types of pellet mills: flat die and ring die.

- Flat die pellet mills have a flat die with holes that the material is forced through.

- Ring die pellet mills have a rotating die with holes that the material is forced through.

- Ring die pellet mills are more common than flat die pellet mills, as they can produce higher quality pellets at a higher production rate.

7. What are the factors to consider when selecting a pellet mill?

- The capacity of the mill.

- The type of raw materials that will be used.

- The desired quality of the pellets.

- The budget available.

8. What are the advantages and disadvantages of using pellets as a fuel?

Advantages

- Pellets are a renewable resource.

- Pellets are a clean-burning fuel.

- Pellets are a relatively inexpensive fuel.

- Pellets are easy to store and transport.

Disadvantages

- Pellets are not as energy-dense as other fuels, such as coal or natural gas.

- Pellets can be difficult to find in some areas.

- Pellets can be expensive to produce.

9. What are the different applications for pellets?

- Pellets can be used as a fuel for heating homes and businesses.

- Pellets can be used as a fuel for power plants.

- Pellets can be used as a fuel for industrial processes.

- Pellets can be used as an animal feed.

- Pellets can be used as a soil amendment.

10. What is the future of the pellet industry?

The pellet industry is expected to grow in the coming years, as more and more people are looking for sustainable and affordable energy sources.

- The growing demand for pellets is expected to lead to increased investment in pellet production facilities.

- The development of new technologies is expected to make pellet production more efficient and affordable.

- The increasing availability of pellets is expected to make them a more attractive option for consumers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pellet Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pellet Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pellet Mill Operators are responsible for the safe and efficient operation of pellet mills, ensuring that they produce high-quality pellets that meet the required specifications.

1. Operation and monitoring

Operate and monitor pellet mills to ensure proper feeding of raw materials and production of pellets.

- Control and adjust process parameters, such as temperature, pressure, and moisture content, to optimize pellet quality.

- Monitor and troubleshoot equipment performance to identify and resolve issues promptly.

2. Maintenance and Repair

Perform routine maintenance and repairs on pellet mills and associated equipment.

- Inspect, clean, and lubricate equipment to prevent breakdowns and ensure optimal performance.

- Troubleshoot and repair mechanical and electrical issues to minimize downtime.

3. Quality Control

Conduct quality control checks on pellets to ensure they meet specifications.

- Sample and test pellets to assess their properties, such as size, density, and durability.

- Make adjustments to the production process as needed to maintain product quality.

4. Safety and Compliance

Maintain a safe and compliant work environment.

- Follow all safety protocols and procedures to prevent accidents and injuries.

- Comply with environmental regulations and ensure proper waste disposal.

Interview Tips

Preparing thoroughly for your Pellet Mill Operator interview is crucial for success. Here are some tips to help you ace it:

1. Research the company

Learn about the company’s history, products, and values. This shows that you’re genuinely interested in the opportunity and have taken the time to understand their business.

- Visit the company’s website.

- Read industry news and articles.

- Connect with current or former employees on LinkedIn.

2. Practice your answers

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers clearly and concisely.

- Use the STAR (Situation, Task, Action, Result) method to structure your answers.

- Focus on highlighting your skills and experience that are relevant to the job.

- Get feedback from a friend or family member on your answers.

3. Be prepared to talk about safety

Safety is paramount in a pellet mill operation. Be prepared to discuss your understanding of safety protocols and procedures.

- Highlight any safety certifications or training you have.

- Describe your experience with hazard identification and risk assessment.

- Explain how you would handle a safety incident.

4. Show your passion

Let the interviewer know that you’re passionate about pellet mill operation and eager to contribute to the company’s success.

- Share your knowledge about pellet mill technology and advancements.

- Discuss your interest in continuous improvement and innovation.

- Express your enthusiasm for working in a team environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pellet Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.