Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pelletizer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pelletizer so you can tailor your answers to impress potential employers.

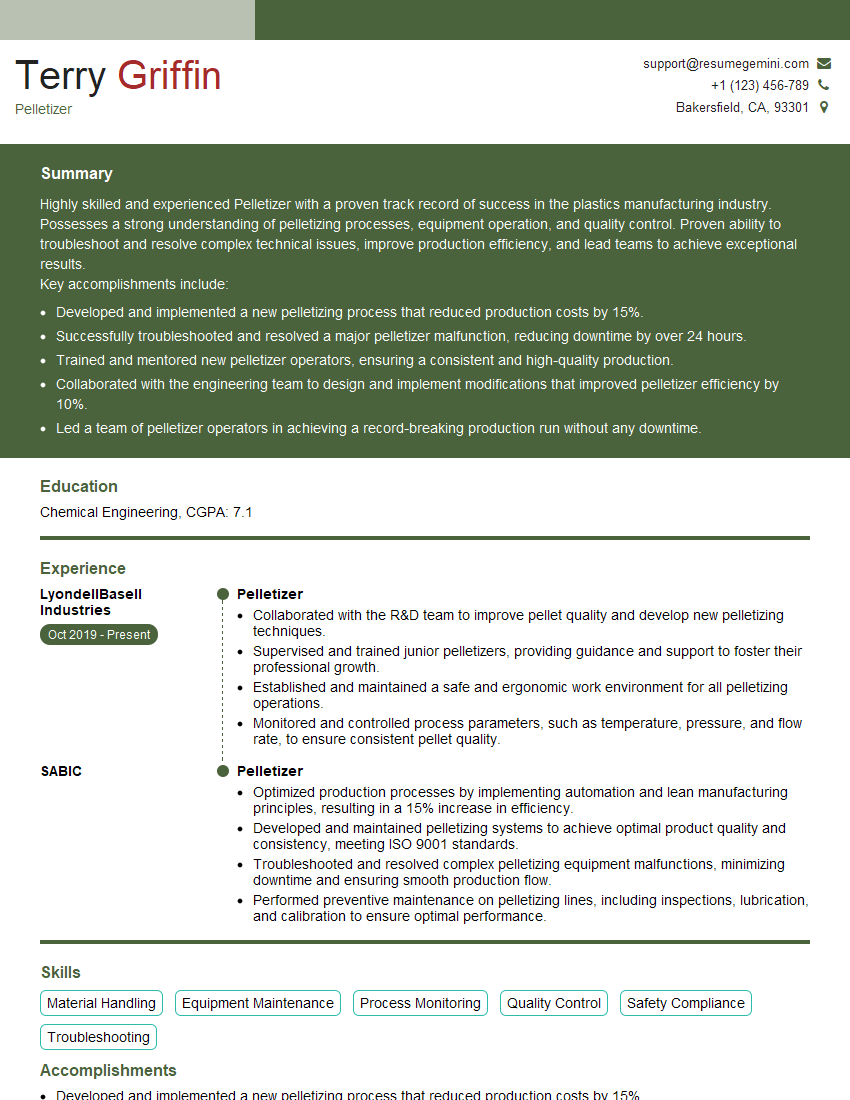

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pelletizer

1. How would you define the role of a Pelletizer in a production setting?

- A Pelletizer is responsible for operating and maintaining the equipment used to produce pellets from a variety of materials.

- The role involves monitoring the production process, adjusting equipment settings, and troubleshooting any issues that may arise.

- Pelletizers must have a good understanding of the pelletizing process and the equipment used to perform it.

- They must also be able to work independently and as part of a team.

2. Can you describe the pelletizing process in detail?

of the answer

- The pelletizing process involves converting a powdery or granular material into small, cylindrical pellets.

- This is typically done by forcing the material through a die with holes of a specific size.

- The resulting pellets are then cooled and dried.

- The pelletizing process can be used to produce a variety of materials, including plastics, fertilizers, and animal feed.

Subheading of the answer

- As a Pelletizer, I would be responsible for monitoring the pelletizing process and ensuring that the pellets are produced to the correct specifications.

- I would also be responsible for troubleshooting any issues that may arise during the process.

3. What are the common challenges faced by Pelletizers in a production setting?

- One of the most common challenges faced by Pelletizers is ensuring that the pellets are produced to the correct size and shape.

- Other challenges include maintaining the equipment, troubleshooting process issues, and working in a fast-paced environment.

4. How would you troubleshoot a problem with a pelletizer that is not producing pellets to the correct size?

- If a pelletizer is not producing pellets to the correct size, there are a number of potential causes.

- One possibility is that the die is worn or damaged.

- Another possibility is that the material being pelletized is not properly prepared.

- I would start by checking the die for wear or damage.

- If the die is damaged, it will need to be replaced.

- If the die is not damaged, I would then check the material being pelletized.

- If the material is not properly prepared, it may need to be ground or sieved before it can be pelletized.

5. What are the safety precautions that must be taken when operating a pelletizer?

- There are a number of safety precautions that must be taken when operating a pelletizer.

- These include wearing appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- It is also important to keep the work area clean and free of debris.

- Pelletizers should also be aware of the potential hazards of the materials they are working with.

6. What are the maintenance procedures that must be performed on a pelletizer?

- Regular maintenance is essential to keep a pelletizer running smoothly.

- This includes cleaning the equipment, lubricating moving parts, and inspecting the die for wear or damage.

- It is also important to keep the work area clean and free of debris.

7. How would you improve the efficiency of a pelletizing operation?

- There are a number of ways to improve the efficiency of a pelletizing operation.

- One way is to optimize the process parameters, such as the temperature and pressure.

- Another way is to use a more efficient die design.

- Finally, it is important to keep the equipment well-maintained.

8. What are the different types of pelletizers?

- There are a number of different types of pelletizers, each with its own advantages and disadvantages.

- The most common type of pelletizer is the flat die pelletizer.

- Other types of pelletizers include the ring die pelletizer and the conical die pelletizer.

9. What are the different materials that can be pelletized?

- A wide variety of materials can be pelletized, including plastics, metals, and biomass.

- The type of material being pelletized will determine the type of pelletizer that is used.

10. What are the applications of pelletized materials?

- Pelletized materials have a wide variety of applications, including use as fuel, fertilizer, and animal feed.

- Pellets are also used in a variety of industrial applications, such as the production of plastics and pharmaceuticals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pelletizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pelletizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pelletizers are responsible for operating and maintaining pelletizing machines, which produce pellets from a variety of materials including plastics, metals, and chemicals.

1. Machine operation

Operate pelletizing machines to produce pellets that meet the required specifications.

- Monitor machine performance and make adjustments as needed.

- Troubleshoot and resolve machine problems.

2. Materials handling

Handle and store materials used in the pelletizing process.

- Load materials into the pelletizing machine.

- Unloading pellets from the machine.

- Inspect pellets for quality.

3. Quality control

Perform quality control checks on pellets.

- Test pellets for size, shape, and other properties.

- Maintain records of quality control results.

4. Maintenance and repair

Perform routine maintenance and repairs on pelletizing machines.

- Lubricate and clean machines.

- Identify and troubleshoot machine problems.

- Perform minor repairs.

Interview Tips

Here are some tips to help you ace your Pelletizer interview:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions about your qualifications and why you’re interested in the job.

- Visit the company website.

- Read the job description carefully.

- Look for news articles or other information about the company.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to answer questions.

- Focus on your skills and experience that are relevant to the job.

- Quantify your results whenever possible.

3. Be prepared to talk about your experience with pelletizing machines

If you have any experience operating or maintaining pelletizing machines, be sure to highlight it in your interview. This will show the interviewer that you have the skills and knowledge necessary to be successful in the position.

- Describe the different types of pelletizing machines you’ve worked with.

- Explain how you troubleshoot and resolve machine problems.

- Discuss your experience with quality control procedures.

4. Be enthusiastic and positive

The interviewer wants to know that you’re excited about the opportunity to work as a Pelletizer. Be enthusiastic and positive throughout the interview. This will make a good impression on the interviewer and will show that you’re eager to learn and contribute to the company.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be prepared to ask questions about the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pelletizer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.