Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pencil Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

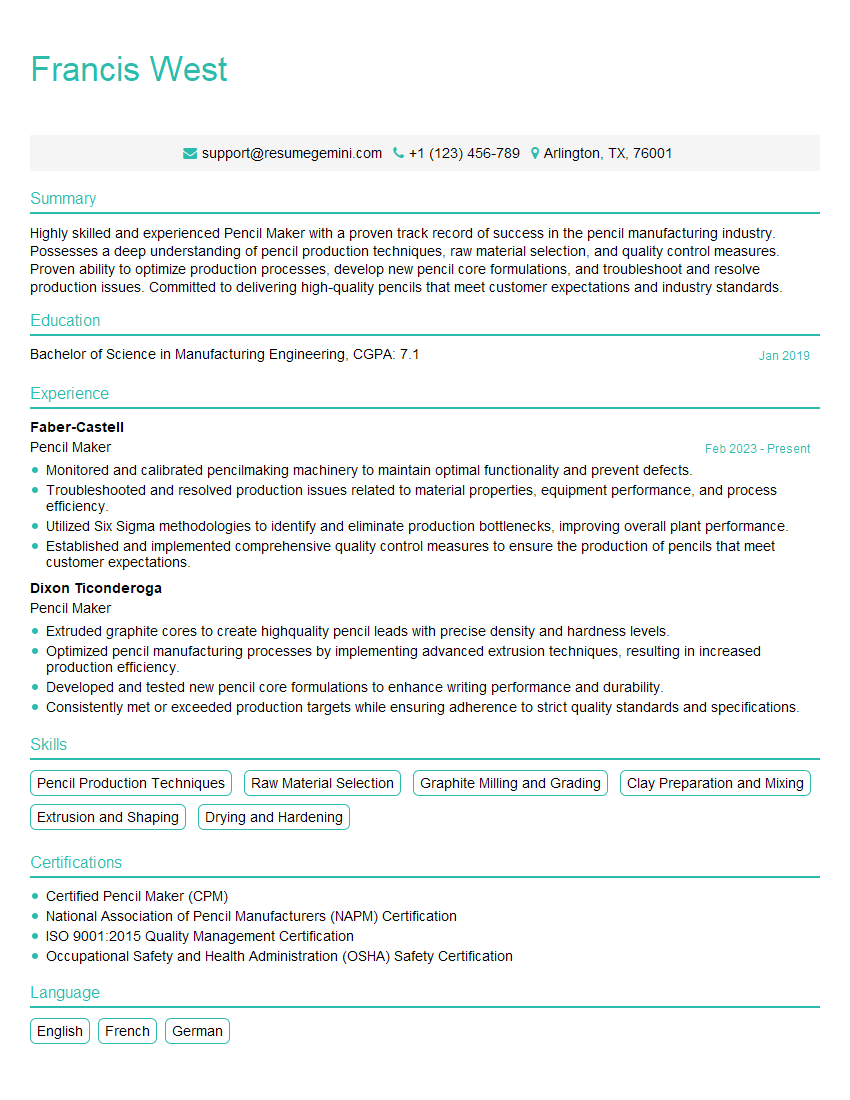

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pencil Maker

1. Can you give me an overview of the pencil-making process?

- Cutting Logs: Trees are felled and cut into logs, which are then debarked.

- Treating Logs: Logs are treated with preservatives to prevent decay and insects.

- Production of Graphite Cores: Graphite is mined and processed into fine powder, which is then mixed with clay and binder to form cores.

- Extrusion: The cores are extruded through a die, forming long, thin graphite sticks.

- Pencil Assembly: Graphite sticks are inserted into wooden shafts, which are glued in place.

- Finishing: Pencils are sanded, painted, and labeled before being packaged.

2. What are the key factors that determine the quality of a pencil?

Raw Materials

- Graphite: The quality of graphite used influences the darkness and smoothness of the writing.

- Wood: The type and quality of wood affect the durability and sharpenability of the pencil.

Manufacturing Process

- Core Extrusion: Consistent core diameter and hardness ensure smooth writing.

- Pencil Assembly: Proper glue distribution and secure shafts prevent breakage.

- Finishing: Smooth sanding and high-quality paint protect the pencil and enhance its appearance.

3. What are the different types of pencils available, and what are their applications?

- Graphite Pencils: General writing and sketching, available in various hardness grades.

- Colored Pencils: Drawing and art, offer a wide range of colors.

- Mechanical Pencils: Retractable lead, convenient for writing and drawing.

- Erasable Pencils: Allow for easy erasing and rewriting, ideal for sketching.

- Carpenter Pencils: Durable for marking wood and other materials.

4. Can you describe the extrusion process in pencil manufacturing?

- Graphite Mixture: Graphite powder, clay, and binder are mixed to create the graphite core mixture.

- Extruder: The mixture is heated and forced through a precision die, forming a continuous graphite rod.

- Diameter and Hardness: The size of the die opening determines the diameter of the core, while the composition of the mixture affects its hardness.

- Drying: The extruded rod is dried to remove moisture and stabilize its properties.

- Cutting: The dried rod is cut into individual graphite sticks of the desired length.

5. How do you ensure the consistent quality of graphite cores?

- Raw Material Inspection: Examine graphite and clay for impurities and ensure compliance with specifications.

- Quality Control Measures: Monitor extrusion parameters, such as temperature, pressure, and die size, to maintain consistent core dimensions.

- Hardness Testing: Use specific equipment to measure the hardness of extruded cores and compare them against predetermined standards.

- Breakage Testing: Conduct tests to assess the durability of the cores by resisting breakage during assembly and sharpening.

- Documentation and Traceability: Maintain records of inspection and testing results to track the quality of each batch.

6. What are the common defects that can occur in pencil production, and how do you prevent them?

Graphite Core Defects

- Breakage: Caused by improper extrusion or drying, can be prevented by optimizing process parameters.

- Inconsistent Hardness: Variations in core composition or extrusion can lead to uneven hardness across the core.

Pencil Assembly Defects

- Cracking: Poorly glued joints or inadequate drying can cause shafts to crack during use.

- Gaps: Insufficient glue or improper alignment can result in gaps between the core and the shaft.

Surface Defects

- Roughness: Inconsistent sanding can create rough surfaces, affecting the appearance and feel of the pencil.

- Blistering: Improper drying or paint defects can lead to blisters or bubbles on the pencil surface.

7. Can you explain the role of wood in pencil manufacturing?

- Physical Support: Wood provides structural support for the graphite core, preventing breakage during writing and sharpening.

- Grip: The wood surface provides a comfortable grip for writing, reducing fatigue and improving control.

- Durability: The type of wood used determines the overall durability of the pencil, affecting its resistance to wear and tear.

- Aesthetic Appeal: The grain and color of the wood contribute to the visual appeal of the pencil.

8. What are the key factors to consider when selecting wood for pencil making?

- Straightness: Straight-grained wood ensures smooth sharpening and prevents breakage during use.

- Grain Density: High-density wood provides better support for the core, reducing the risk of cracking.

- Sharpness: The wood should be soft enough to sharpen easily without splintering or crumbling.

- Durability: The wood species should have good resistance to wear and tear, ensuring the pencil’s longevity.

- Availability and Cost: The wood should be readily available and cost-effective to maintain production efficiency.

9. Can you describe the importance of finishing operations in pencil manufacturing?

- Appearance Enhancement: Sanding and painting improve the pencil’s aesthetic appeal by removing imperfections and providing a smooth surface.

- Protection: Finishing treatments, such as varnishing, protect the pencil from moisture, dirt, and other environmental factors.

- Grip Improvement: Painting the pencil with a textured finish can enhance the grip, providing better writing control.

- Branding: Finishing operations allow for printing or stamping of logos and other branding elements onto the pencil.

10. What are the latest trends and innovations in pencil manufacturing?

- Sustainable Materials: Use of recycled wood and eco-friendly paints to reduce environmental impact.

- Advanced Core Technology: Development of durable, smooth-writing graphite cores with improved break resistance.

- Ergonomic Designs: Pencils with ergonomic grips and balanced weight distribution for writing comfort.

- Multifunctional Pencils: Pencils with built-in erasers, sharpeners, or other features for convenience and versatility.

- Digital Integration: Incorporation of digital elements, such as sensors for pressure sensitivity or connectivity with writing devices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pencil Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pencil Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pencil makers are responsible for the production of pencils. They work in a variety of settings, including factories, workshops, and home studios.

1. Create Pencils

Pencil makers create pencils by shaping and assembling various materials. They may use wood, graphite, clay, and other materials to create pencils.

- Cut and shape wood or other materials into pencil barrels

- Insert graphite or other writing material into the pencil barrels

- Attach erasers to the pencils

- Sharpen the pencils

2. Maintain Equipment

Pencil makers maintain equipment used in the production of pencils. They may clean, repair, and calibrate equipment to ensure its proper functioning.

- Clean and lubricate machinery

- Inspect and repair equipment

- Calibrate equipment to ensure accuracy

3. Supervise Production

Pencil makers may supervise the production of pencils. They may oversee the work of other employees and ensure that production meets quality standards.

- Assign tasks to employees

- Monitor production progress

- Ensure that production meets quality standards

- Troubleshoot production problems

4. Other Responsibilities

Pencil makers may perform other responsibilities, such as:

- Develop new pencil designs

- Test new pencil materials

- Train new employees

- Maintain inventory

Interview Tips

To ace an interview for a Pencil Maker position, it is important to be prepared and to demonstrate your knowledge and skills. Here are some tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

- Review the job description

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to prepare your answers to these questions so that you can deliver them confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Practice your answers

Once you have prepared your answers to common interview questions, it is important to practice them. This will help you feel more confident and relaxed during the interview.

- Practice answering questions with a friend or family member

- Record yourself answering questions and then listen back to them

- Practice answering questions in front of a mirror

4. Be yourself

It is important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be genuine and let your personality shine through.

- Don’t try to be someone you’re not

- Be genuine and let your personality shine through

- Answer questions honestly and thoughtfully

5. Follow up

After the interview, be sure to follow up with the interviewer. This shows that you are interested in the position and that you are serious about getting the job.

- Send a thank-you note to the interviewer

- Follow up with the interviewer a week or two later

- Keep the interviewer updated on your progress

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pencil Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.