Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Perforating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

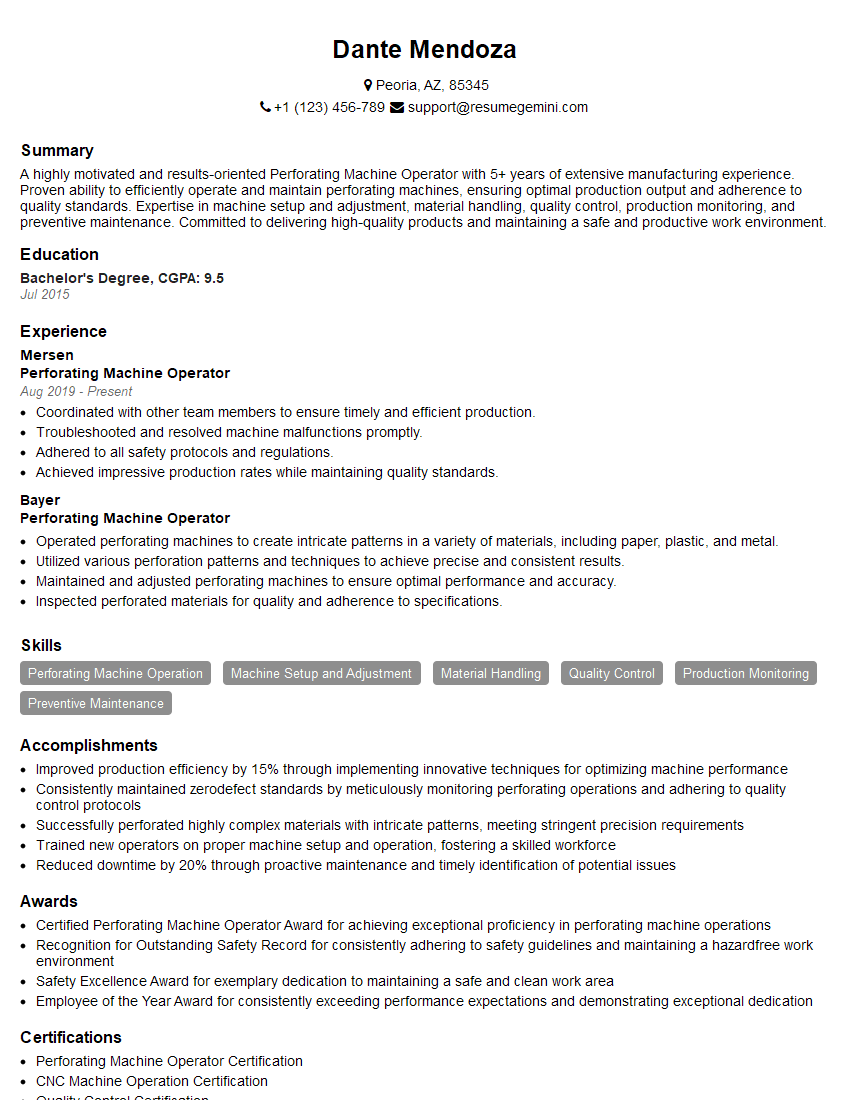

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Perforating Machine Operator

1. Explain the process of setting up and operating a perforating machine?

- Inspect the machine for any damage or issues.

- Adjust the machine settings according to the job requirements, including the punching speed, depth, and pattern.

- Securely fasten the material to the worktable using clamps or a vacuum system.

- Start the machine and guide the material through the punching process.

- Monitor the progress of the operation and make any necessary adjustments to ensure precision and quality.

- Shut down the machine once the perforating process is complete.

2. What are the different types of perforating dies?

Types of Perforating Dies

- Round Dies: Produce circular holes.

- Slot Dies: Create elongated or rectangular holes.

- Shaped Dies: Cut specific shapes, such as stars, hearts, or letters.

- Multi-Dies: Punch multiple holes in a single stroke.

- Combination Dies: Combine different types of holes in a single die.

Selection Considerations

- Material thickness and hardness

- Desired hole shape and size

- Production speed and volume

3. How do you ensure the accuracy and precision of perforated holes?

- Use sharp and properly sized dies.

- Calibrate the machine regularly to maintain accuracy.

- Ensure that the material is securely fastened and aligned before punching.

- Monitor the punching process carefully and make adjustments as needed.

- Inspect the perforated holes regularly for defects or deviations.

4. How do you troubleshoot common problems that may arise during the perforating process?

- Ragged or torn holes: Dull or damaged dies, improper material alignment.

- Holes in the wrong location: Incorrect machine setup, material slippage.

- Difficulty feeding the material: Worn or misaligned feed rollers, improper material thickness.

- Machine vibration or noise: Loose components, unbalanced dies.

- Excessive wear on dies: Incorrect punching speed or material hardness.

5. How do you maintain and clean a perforating machine?

- Regularly inspect and clean the machine, including removing any debris or scrap material.

- Lubricate moving parts as per the manufacturer’s instructions.

- Sharpen or replace dies as needed to maintain accuracy.

- Check the machine’s calibration and adjust if necessary.

- Follow manufacturer’s recommendations for maintenance intervals and procedures.

6. How do you ensure the safety of yourself and others when operating a perforating machine?

- Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Keep the work area clean and free of tripping hazards.

- Securely fasten the material to the worktable to prevent it from moving during operation.

- Never reach into the punching area while the machine is running.

- Be aware of the location of the emergency stop button and know how to use it in case of an emergency.

7. What is the difference between perforation and die-cutting?

Perforation

- Partially cuts the material, creating a series of connected holes.

- Weaken the material along the perforation lines, allowing it to be easily torn or separated.

- Used for applications such as creating tear-off tabs, postage stamps, and tickets.

Die-Cutting

- Completely cuts through the material, creating individual shapes.

- Uses sharp dies to produce clean and precise cuts.

- Used for applications such as manufacturing packaging, labels, and gaskets.

8. Can you explain the concept of dwell time in the perforating process?

- Dwell time refers to the amount of time the die remains in contact with the material after the punching operation.

- Controls the shape and quality of the perforated holes.

- A longer dwell time can create cleaner and more precise holes, while a shorter dwell time can produce ragged or incomplete holes.

- Dwell time must be optimized based on the material thickness, hole size, and desired results.

9. What are the key factors to consider when selecting a perforating machine?

- Material type and thickness

- Desired hole size, shape, and pattern

- Production speed and volume requirements

- Available machine space and power supply

- Ease of operation and maintenance

- Safety features and compliance with industry standards

10. How do you stay up-to-date with the latest advancements and best practices in perforating technology?

- Attend industry trade shows and conferences

- Read technical journals and articles

- Participate in online forums and webinars

- Consult with manufacturers and suppliers

- Seek continuing education opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Perforating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Perforating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Perforating Machine Operator plays a crucial role in the manufacturing process by operating and maintaining machines that create precise holes or perforations in various materials.

1. Machine Operation

Proficiently operate perforating machines to create holes in materials such as metal, plastic, or paper.

- Interpret technical drawings, blueprints, and instructions to determine machine settings.

- Load materials onto the machine, ensuring proper alignment and tension.

2. Machine Maintenance

Perform routine maintenance and troubleshooting of perforating machines.

- Clean and lubricate machine components regularly.

- Identify and rectify mechanical or electrical malfunctions.

3. Quality Control

Inspect perforated materials to ensure they meet specifications.

- Monitor hole size, spacing, and precision using measuring and inspection tools.

- Document quality control checks and report any deviations to management.

4. Production Support

Collaborate with other team members to ensure smooth production flow.

- Assist in material handling and setup of other machines.

- Contribute to productivity improvement and process optimization.

Interview Tips

To ace an interview for a Perforating Machine Operator position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and specific requirements for the role. This shows your interest and preparation.

- Review their website, LinkedIn page, and industry news.

- Identify the key responsibilities and qualifications for the position.

2. Highlight Relevant Skills and Experience

Showcase your technical skills, including perforating machine operation, maintenance, and quality control.

- Quantify your experience with specific examples and metrics.

- Emphasize your ability to work independently and as part of a team.

3. Practice and Prepare Responses

Practice answering common interview questions related to the job responsibilities, technical abilities, and work experience.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Prepare questions for the interviewer to demonstrate your engagement and interest.

4. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately for the interview and arrive on time to show your professionalism and respect.

- Choose business attire or neat and clean work clothes.

- Arrive 10-15 minutes early to allow for any unexpected delays.

5. Be Confident and Enthusiastic

Convey confidence in your abilities and enthusiasm for the role. Nonverbal cues, such as maintaining eye contact and a positive body language, can make a significant impact.

- Speak clearly and concisely, avoiding fillers and excessive jargon.

- Show your passion for the industry and your desire to contribute to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Perforating Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.