Are you gearing up for a career in Perforator Loader? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Perforator Loader and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

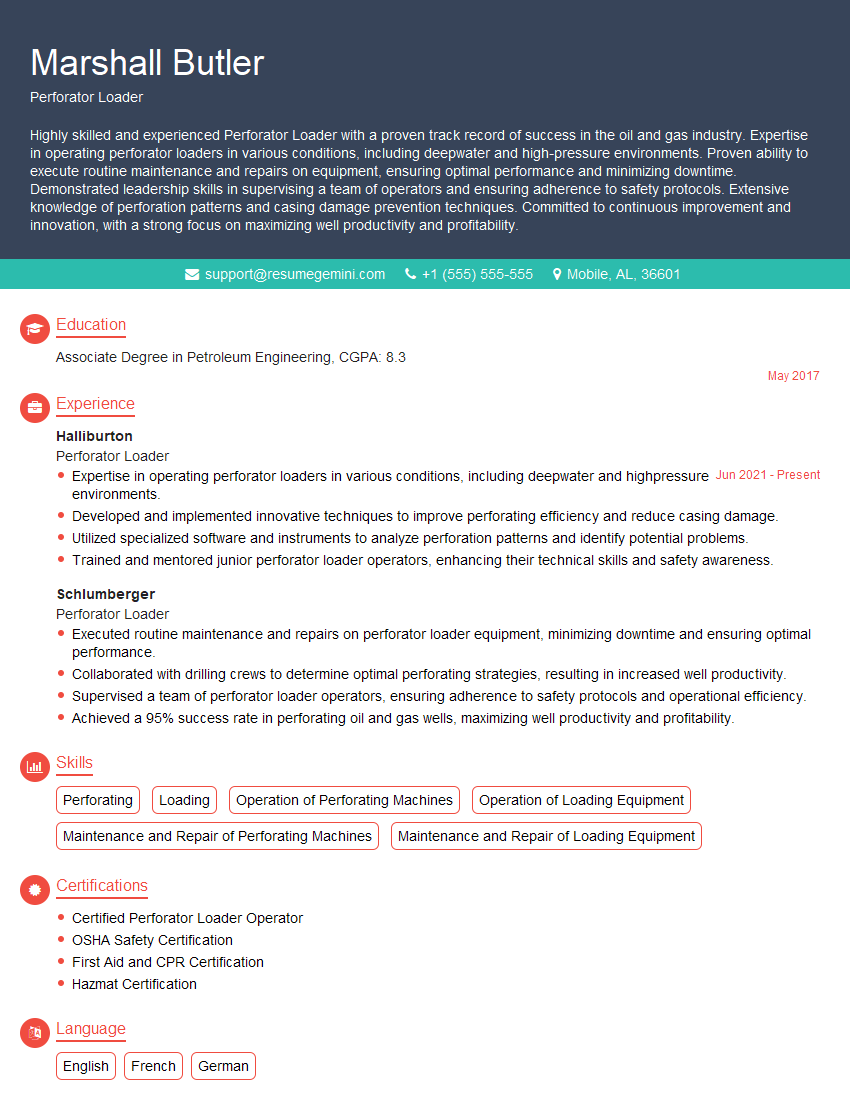

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Perforator Loader

1. What is the purpose of a perforator loader, and what are its key components?

A perforator loader is a specialized piece of equipment used in underground mining operations to drill holes in rock formations for blasting purposes. Its key components include:

- A drill head equipped with tungsten carbide inserts for cutting through rock.

- A hydraulic or electric motor to power the drill head.

- A boom or mast to position the drill head accurately.

- A carriage or crawler system to move the loader along the mining face.

- A dust collection system to minimize airborne dust during drilling.

2. Describe the different types of perforator loaders and their specific applications.

Diesel-powered perforator loaders

- Commonly used in underground mining operations.

- Powered by diesel engines, providing high power and mobility.

- Suitable for large-scale mining operations with ample ventilation.

Electric-powered perforator loaders

- Preferred in confined spaces with limited ventilation.

- Powered by electric motors, ensuring zero emissions.

- Suitable for smaller-scale mining operations or areas with environmental concerns.

Hydraulic perforator loaders

- Versatile and powerful, used in various mining applications.

- Powered by hydraulic systems, offering precise control and high efficiency.

- Suitable for both underground and surface mining operations.

3. Explain the process of operating a perforator loader, including safety considerations.

Operating a perforator loader involves several steps:

- Pre-operational checks: Inspect the loader, ensuring all components are in good condition and properly lubricated.

- Positioning: Position the loader at the desired drilling location, ensuring stability and proper drilling angle.

- Drilling: Engage the drill head and adjust the drilling parameters (speed, pressure, etc.) based on rock conditions.

- Hole cleaning: Periodically remove rock cuttings from the hole using compressed air or water flushing to prevent jamming.

- Safety considerations: Wear appropriate personal protective equipment (PPE), maintain a safe distance from the drilling area, and be aware of potential hazards such as falling rocks or electrical hazards.

4. What are the common maintenance tasks required for a perforator loader, and how often should they be performed?

Regular maintenance is crucial for the optimal performance and longevity of a perforator loader. Common maintenance tasks include:

- Daily maintenance: Inspecting fluid levels, checking for leaks, and cleaning the loader.

- Weekly maintenance: Lubricating moving parts, checking drill bit sharpness, and tightening bolts.

- Monthly maintenance: Replacing filters, inspecting hydraulic systems, and performing minor repairs.

- Quarterly maintenance: Thorough inspection of all components, including the drill head, boom, and carriage.

- Annual maintenance: Overhauling the loader, replacing major components, and conducting performance tests.

5. Describe the safety protocols and emergency procedures associated with perforator loader operation.

Safety is paramount when operating a perforator loader. Safety protocols include:

- Wearing appropriate PPE, including hard hat, safety glasses, earplugs, and gloves.

- Maintaining a safe drilling area, free from tripping hazards and loose rocks.

- Inspecting the drill site for potential hazards before starting work.

- Following proper lockout/tagout procedures before performing maintenance or repairs.

- Emergency procedures include responding to equipment malfunctions, rock falls, or other incidents.

6. How do you troubleshoot common problems encountered while operating a perforator loader?

Troubleshooting common problems is essential for minimizing downtime and ensuring efficient operation. Some common problems include:

- Drill head jamming: Check for blunt drill bits, insufficient hole cleaning, or excessive rock pressure.

- Loss of hydraulic power: Inspect hydraulic hoses for leaks, check fluid levels, and ensure the hydraulic system is functioning properly.

- Electrical problems: Verify electrical connections, check fuses, and troubleshoot any circuit malfunctions.

- Engine issues: Check fuel levels, inspect air filters, and diagnose any mechanical problems with the engine.

7. What are the performance metrics used to evaluate the efficiency of a perforator loader?

Performance metrics include:

- Drilling speed: Measured in meters per hour or feet per hour, indicating the rate at which the loader drills holes.

- Penetration rate: The depth of hole drilled per unit of time, expressed in meters per minute or feet per minute.

- Hole quality: Assessing the straightness, depth, and diameter of the drilled holes to ensure they meet the required specifications.

- Utilization rate: The percentage of time the loader is actively drilling, excluding downtime for maintenance or repairs.

- Energy consumption: Monitoring the fuel or electricity consumption of the loader to optimize energy efficiency.

8. How do you stay up-to-date with advancements in perforator loader technology and industry best practices?

To stay current with advancements, I engage in the following:

- Attending industry conferences and workshops.

- Reading technical publications and journals.

- Consulting with equipment manufacturers and industry experts.

- Participating in online forums and discussion groups.

- Seeking opportunities for professional development and training.

9. Describe a situation where you successfully resolved a complex problem while operating a perforator loader.

Once, our perforator loader encountered a sudden drop in drilling speed. After troubleshooting, I identified a clogged hydraulic filter as the culprit. By promptly replacing the filter, I restored the loader’s performance, minimizing downtime and ensuring efficient operation.

10. How would you approach optimizing the drilling process to achieve maximum efficiency and productivity?

To optimize drilling, I would consider the following strategies:

- Selecting the appropriate drill bits and cutting tools for the specific rock conditions.

- Optimizing drilling parameters (speed, pressure, rotation) based on rock properties.

- Implementing a regular maintenance schedule to prevent breakdowns and ensure peak performance.

- Training operators to follow best practices and identify potential problems early on.

- Utilizing technology, such as automated drilling systems, to enhance efficiency and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Perforator Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Perforator Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Perforator Loaders are responsible for the safe and efficient operation of perforator loading equipment. They play a crucial role in the mining industry, ensuring that boreholes are properly prepared for blasting operations. Key job responsibilities include:

1. Equipment Operation

Operate perforator loading equipment, including drills, rods, and explosives, to create boreholes for blasting.

2. Hole Preparation

Prepare boreholes by cleaning them of debris, inserting explosives, and tamping them down to ensure optimal blasting results.

3. Safety and Compliance

Adhere to all safety regulations and procedures while operating equipment and handling explosives.

4. Maintenance and Inspection

Perform regular maintenance and inspections of equipment to ensure it is in good working condition.

Interview Tips

Preparing for a Perforator Loader interview requires thorough research and practice. Here are some essential tips:

1. Research the Company and Position

Research the mining company and the specific role of a Perforator Loader within their operations. This will help you understand the industry and the company’s expectations.

2. Highlight Relevant Experience

Emphasize your experience in operating perforator loading equipment and handling explosives safely. Quantify your accomplishments whenever possible, using specific examples and metrics.

3. Demonstrate Technical Knowledge

Show your understanding of the technical aspects of perforator loading, including equipment specifications, blasting techniques, and safety protocols.

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your work style and values. Prepare for questions about teamwork, problem-solving, and safety consciousness.

5. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself” and “Why should we hire you?” Tailor your responses to the specific requirements of the Perforator Loader role.

6. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s safety culture, training opportunities, and growth potential.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Perforator Loader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Perforator Loader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.