Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Perforator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

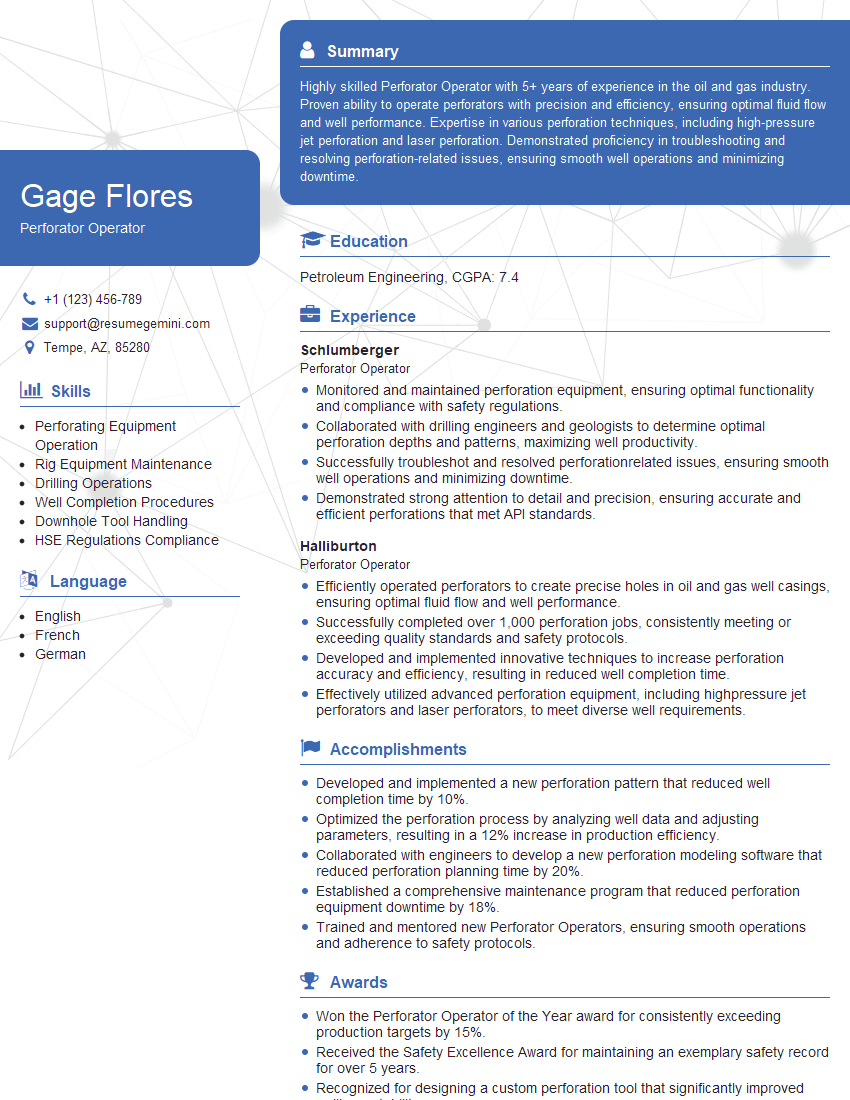

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Perforator Operator

1. Explain the principles and different types of perforation techniques used in the oil and gas industry?

- Perforation techniques create perforations, controlled openings in the casing and cement, which allow reservoir fluids to flow into the wellbore.

- Types of perforation techniques include:

- Jet perforating: Uses a high-pressure струя to create perforations.

- Shaped charge perforating: Uses explosive charges to create perforations.

- Abrasive jet perforating: Uses a high-pressure jet of abrasive material to create perforations.

- The selection of perforation technique depends on factors such as wellbore conditions, formation properties, and production objectives.

2. Describe the equipment involved in a perforation operation and their functions?

- Perforating guns: Contain the shaped charges or jet nozzles used to create perforations.

- Control panels: Used to initiate the perforation operation and control the firing sequence.

- Perforating lines: Connect the control panel to the perforating guns in the wellbore.

- Wireline unit: Used to deploy and retrieve the perforating guns in the wellbore.

3. What are the safety considerations and precautions that must be taken during a perforation operation?

- Proper well control procedures must be followed to prevent uncontrolled flow of formation fluids.

- The well should be isolated using kill fluids or other methods to prevent the release of hydrocarbons or other hazardous substances.

- Personnel should wear appropriate personal protective equipment (PPE) and be trained in emergency procedures.

4. How do you calculate the shot density and perforation phasing for a given application?

- Shot density: Determined by the desired flow rate and formation characteristics.

- Perforation phasing: Refers to the angular spacing between perforations and can affect flow distribution.

- Calculations involve factors such as formation permeability, porosity, and wellbore diameter.

5. What are the common problems that can occur during a perforation operation and how can they be addressed?

- Plugged perforations: Can be caused by debris or formation damage and can be addressed using cleanup techniques.

- Reduced shot density: Can result from equipment malfunctions or formation conditions and may require additional perforation runs.

- Perforation collapse: Can occur due to high formation stress and can be mitigated by using high-collapse-rated perforating guns.

6. How do you evaluate the effectiveness of a perforation operation?

- Production logging: Used to measure flow rates and identify potential problems.

- Pressure transient analysis: Can provide insights into reservoir connectivity and perforation performance.

- Well testing: Can be used to assess overall well performance, including perforation effectiveness.

7. Describe the different technologies used to enhance perforation performance?

- Underbalanced perforating: Creates perforations while the well is underbalanced, reducing formation damage.

- Through-tubing perforating: Allows perforating operations to be performed without removing the production tubing.

- High-energy density perforating: Uses shaped charges with higher energy density to create deeper and more effective perforations.

8. What is the role of perforation modeling in optimizing perforation operations?

- Perforation modeling software simulates the perforation process and helps optimize shot density, phasing, and other parameters.

- Can predict perforation performance and identify potential problems before field operations.

- Improves operational efficiency and reduces the risk of unsuccessful perforations.

9. How do you stay updated with the latest advancements in perforation technology and best practices?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with other professionals in the field.

- Participate in training programs and certifications.

10. Describe a challenging perforation operation you have encountered and how you successfully addressed it.

- Provide a specific example of a challenging perforation operation, highlighting the problems encountered.

- Explain the steps taken to analyze the situation and develop a solution.

- Describe the implemented solution and its effectiveness in resolving the challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Perforator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Perforator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Perforator Operators are responsible for operating and maintaining perforators, which are machines that create holes in materials.

Their key job responsibilities include:

1. Operating perforators

- Set up and operate perforators to create holes in materials

- Monitor perforators during operation and make adjustments as needed

- Troubleshoot and repair perforators when necessary

2. Maintaining perforators

- Clean and lubricate perforators

- Inspect perforators for wear and tear

- Replace worn or damaged parts

3. Quality control

- Inspect holes created by perforators to ensure they meet specifications

- Reject materials that do not meet specifications

- Maintain records of perforator operations and quality control inspections

4. Safety

- Follow all safety regulations

- Wear appropriate safety gear

- Operate perforators in a safe manner

Interview Tips

To ace an interview for a Perforator Operator position, it is important to prepare and practice your answers. Here are some tips:

1. Research the company and position

This will help you understand the company’s culture and the specific requirements of the position. You can research the company’s website, LinkedIn page, and Glassdoor reviews.

2. Practice your answers to common interview questions

There are many common interview questions that you may be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

3. Be prepared to talk about your experience

When answering questions about your experience, be sure to highlight your skills and accomplishments. Use specific examples to demonstrate your abilities.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the position and the company’s culture.

5. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

6. Be confident

Confidence is key in any interview. Believe in yourself and your abilities, and let the interviewer know that you are the right person for the job.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Perforator Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.