Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Permastone Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

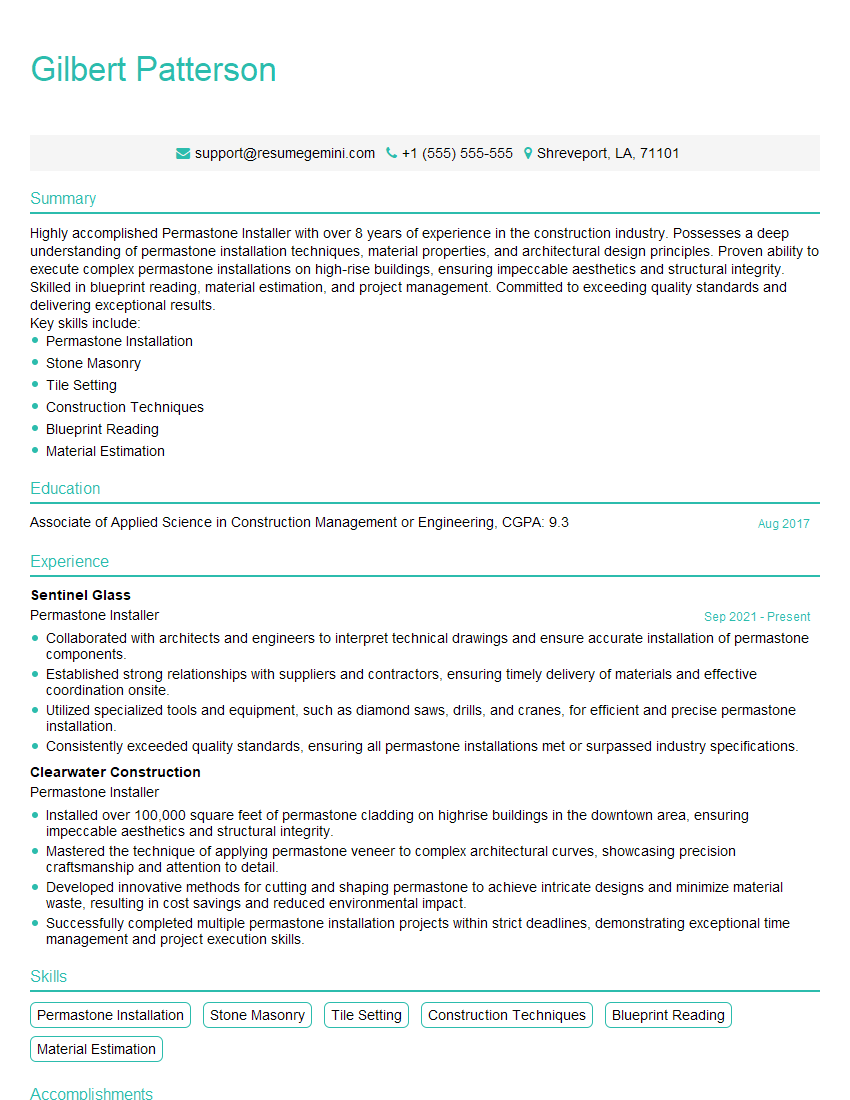

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Permastone Installer

1. What are the different types of Permastone finishes and how do they differ?

Permastone offers a range of finishes to cater to different aesthetic preferences and functional requirements:

- Smooth finish: Provides a sleek and polished appearance, often used for interior applications and surfaces that require low maintenance.

- Textured finish: Adds visual interest and slip resistance, suitable for outdoor areas, flooring, and surfaces that need increased grip.

- Exposed aggregate finish: Reveals the natural beauty of the underlying aggregate stones, providing a rugged and decorative surface for exterior applications.

- Integral color finish: Incorporates color pigments into the Permastone mix, allowing for a wide range of color options and a uniform appearance throughout the entire surface.

- Stamped finish: Imprints patterns or textures into the wet Permastone, creating a unique and decorative surface that mimics natural materials like stone, brick, or wood.

2. What are the critical steps involved in preparing a surface for Permastone installation?

Surface Preparation

- Properly clean the surface to remove any dirt, debris, or contaminants that could affect adhesion.

- Ensure the surface is level and smooth, using a screed or leveling compound if necessary.

- Create a roughened surface by sandblasting or grinding to improve bonding between the Permastone and the substrate.

- Apply a primer or bonding agent to enhance adhesion and prevent moisture penetration.

Formwork

- Install formwork to define the edges and shape of the Permastone surface.

- Ensure the formwork is securely anchored and aligns with the desired dimensions.

- Apply a release agent to the formwork to prevent the Permastone from sticking.

3. How do you ensure proper hydration of Permastone during the curing process?

- Moist curing: Cover the Permastone surface with wet burlap or plastic sheeting to maintain moisture levels and prevent rapid drying.

- Water spray: Regularly mist or spray the Permastone surface with water to keep it hydrated.

- Curing compounds: Apply a water-based curing compound to the surface to form a membrane that retains moisture and reduces evaporation.

- Proper timing: Allow sufficient curing time, typically 7-14 days, depending on environmental conditions and the thickness of the Permastone.

4. What are the common causes of cracking in Permastone and how can they be prevented?

- Excessive shrinkage: Improper curing or rapid drying can lead to shrinkage and cracking.

- Movement in the substrate: Structural movement or settling can cause stress and cracks in the Permastone.

- Improper reinforcement: Inadequate reinforcement, such as insufficient fiber or mesh, can weaken the Permastone and make it more susceptible to cracking.

- Thermal expansion and contraction: Changes in temperature can cause expansion and contraction, leading to cracking if the surface is not properly designed for movement.

- Chemical reactions: Exposure to certain chemicals or salts can deteriorate the Permastone and cause cracking.

5. Describe the steps involved in repairing a damaged Permastone surface.

- Remove damaged material: Chip away or grind down the damaged area to expose the sound Permastone.

- Clean and prepare the surface: Remove any loose debris or contaminants, and roughen the surface to improve bonding.

- Apply bonding agent: Brush or trowel a bonding agent onto the prepared surface.

- Mix and apply repair material: Prepare the Permastone repair material according to the manufacturer’s instructions and apply it to the damaged area.

- Finish and cure: Smooth the repair material and allow it to cure properly, following the same hydration techniques used during the initial installation.

6. What safety precautions should be taken when working with Permastone?

- Wear proper protective gear: Gloves, safety glasses, and a dust mask to protect against dust and debris.

- Handle chemicals carefully: Use appropriate gloves and follow manufacturer’s instructions when handling primers, bonding agents, and curing compounds.

- Avoid inhalation of dust: Wear a dust mask and keep the work area well-ventilated.

- Be aware of electrical hazards: Use caution when operating power tools and ensure proper grounding.

- Follow manufacturer’s guidelines: Always read and follow the manufacturer’s safety instructions for Permastone products.

7. How do you determine the appropriate thickness for a Permastone installation?

- Intended use: Consider the load-bearing requirements and traffic conditions for the specific application.

- Substrate condition: Evaluate the strength and stability of the underlying substrate.

- Spanning distance: Determine the distance between supports or reinforcement to ensure adequate structural integrity.

- Environmental factors: Account for potential temperature fluctuations, moisture exposure, and chemical resistance.

- Industry standards: Refer to manufacturer’s recommendations and industry guidelines for minimum thickness requirements.

8. What techniques can be used to achieve a seamless finish when joining multiple Permastone sections?

- Staggered joints: Overlap adjacent sections slightly and stagger the joints to minimize visible lines.

- Feather edging: Grind or sand the edges of the sections to create a smooth transition.

- Color matching: Use pigments or stains to blend the colors of the sections for a uniform appearance.

- Grinding and polishing: Smooth out the joints using a grinder or polisher to minimize any irregularities.

- Sealants: Apply a clear sealant to the joints to prevent moisture penetration and enhance the overall finish.

9. How do you ensure proper drainage when installing Permastone outdoors?

- Slope the surface: Create a gradual slope to direct water away from the surface.

- Install drainage channels: Integrate channels or grooves into the Permastone to facilitate water flow.

- Provide weep holes: Allow water to escape from the substrate through strategically placed weep holes.

- Use permeable materials: Consider using permeable underlayments or bedding materials to allow water to drain through the system.

- Maintain proper drainage: Regularly clean gutters and drains to prevent blockages that could lead to water buildup.

10. What are the advantages of using Permastone over traditional concrete?

- Superior durability: Permastone is highly resistant to wear, impact, and chemicals, making it ideal for high-traffic areas.

- Aesthetic versatility: Offers a wide range of colors, textures, and finishes, allowing for customized designs and architectural expression.

- Cost-effective: While the initial installation cost may be slightly higher than traditional concrete, Permastone’s durability and low maintenance requirements provide long-term savings.

- Easy maintenance: Requires minimal maintenance, such as occasional cleaning and resealing, to maintain its aesthetic appeal.

- Environmentally friendly: Permastone is a sustainable material made from recycled glass and aggregates, reducing the environmental impact of construction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Permastone Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Permastone Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Permastone Installers play a crucial role in the construction industry, specializing in the installation of architectural veneer and cladding systems made from Permastone, an innovative composite material used in high-rise buildings, commercial properties, and other architectural projects.

1. Installation Expertise

Installers are responsible for accurately and efficiently installing Permastone panels, ensuring they are securely attached to the building structure and meet the highest standards of quality.

2. Site Preparation

Prior to installation, installers prepare the site by reviewing blueprints, determining necessary materials, and setting up the work area to ensure a smooth and efficient installation process.

3. Panel Handling

Installers are trained to handle and move Permastone panels safely and effectively, using specialized equipment and techniques to avoid damage or breakage during the installation process.

4. Precision Installation

Accuracy is paramount in Permastone installation. Installers meticulously align and fasten panels according to the design specifications, ensuring the finished product meets the highest aesthetic and functional standards.

5. Quality Control

Throughout the installation process, installers conduct regular inspections to verify the quality of their work, ensuring that all panels are properly secured and aligned, and that the finished product meets specifications.

6. Safety Compliance

Safety is a top priority in Permastone installation. Installers receive comprehensive training on safety protocols and adhere to industry regulations to minimize risks and ensure a safe work environment.

7. Customer Service

Installers provide excellent customer service by answering questions, addressing concerns, and ensuring customer satisfaction with the final product.

Interview Tips

To ace the interview for a Permastone Installer position, candidates should focus on demonstrating their technical skills, attention to detail, and commitment to safety. Here are some essential interview tips:

1. Research the Company

Before the interview, take the time to research the company and the specific projects they have worked on. This demonstrates your interest and enthusiasm for the role.

2. Highlight Relevant Experience

Emphasize your experience in installing Permastone or similar architectural cladding systems. Quantify your accomplishments whenever possible, using specific examples.

3. Showcase Attention to Detail

Permastone installation requires precision and meticulous attention to detail. Highlight your ability to follow instructions accurately and ensure the highest quality of workmanship.

4. Discuss Safety Protocols

Safety is paramount in this role. Discuss your understanding of industry safety regulations and your commitment to maintaining a safe work environment.

5. Ask Informed Questions

Prepare insightful questions about the company, the project, and the installer’s responsibilities. This shows your engagement and interest in the opportunity.

6. Prepare for Physical Rigors

Be aware that Permastone installation can be physically demanding. Be prepared to discuss your physical capabilities and how you maintain your health and fitness.

7. Dress Professionally

First impressions matter. Dress appropriately for the interview, reflecting the professional nature of the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Permastone Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!