Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Petroleum Refinery Control Panel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

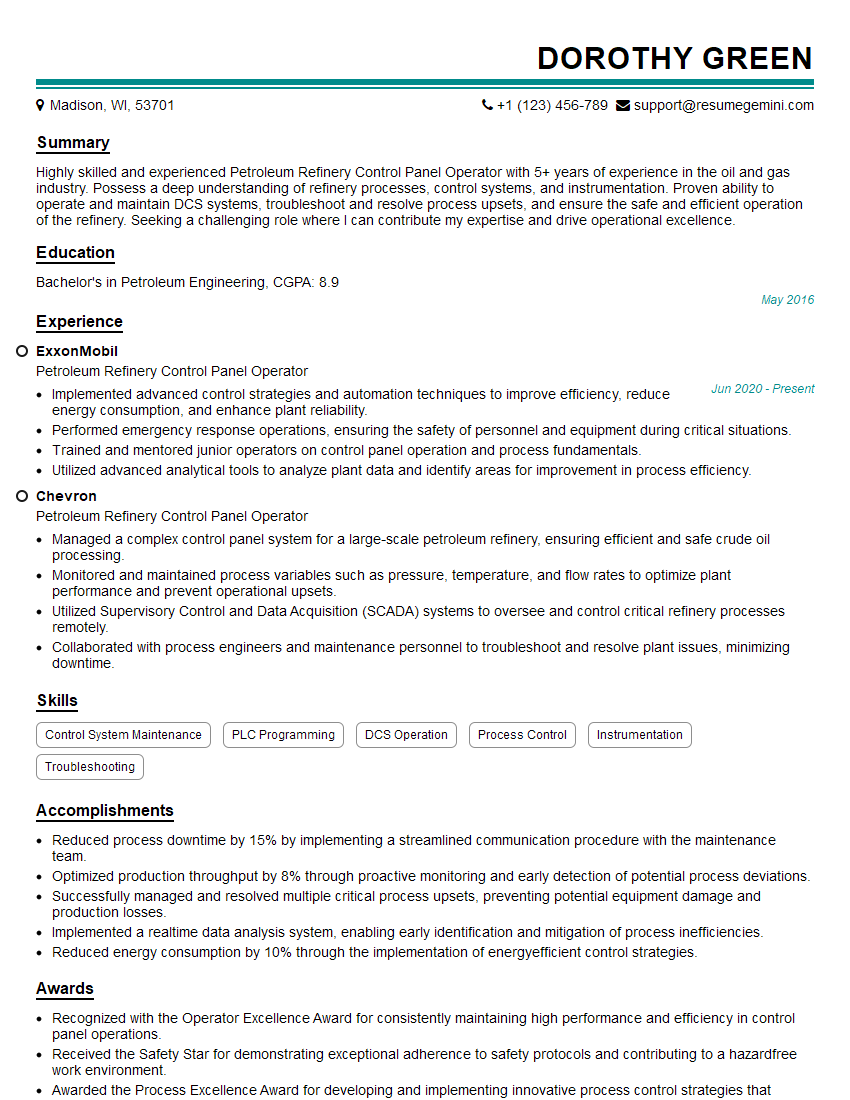

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Petroleum Refinery Control Panel Operator

1. How do you ensure the safe and efficient operation of the control panel in a petroleum refinery?

To ensure the safe and efficient operation of the control panel in a petroleum refinery, I adhere to the following principles:

- Constant Monitoring: I vigilantly monitor all process parameters, including temperature, pressure, flow rates, and valve positions, to identify any deviations from normal operating ranges.

- Immediate Response: When deviations or alarms occur, I promptly investigate the situation and take appropriate corrective actions to maintain process stability and prevent equipment damage.

- Communication and Coordination: I effectively communicate with other operators, supervisors, and engineers to ensure coordination and a swift response to process changes or emergencies.

- Compliance with Procedures: I strictly follow established operating procedures and safety protocols to ensure the safe and compliant operation of the control panel.

- Continuous Improvement: I actively participate in training and development programs to enhance my knowledge and skills, and I contribute to the improvement of operating practices.

2. Describe the role of the distributed control system (DCS) in the operation of a petroleum refinery.

DCS Functions

- Process Control: The DCS receives data from field sensors and actuators and uses it to control process variables within specified ranges.

- Data Acquisition and Monitoring: The DCS collects and stores real-time data, allowing operators to monitor process performance and identify trends.

- Alarm Management: The DCS detects and annunciates alarms when process parameters deviate from normal limits, alerting operators to potential issues.

Importance in Refinery Operations

- Improved Efficiency: The DCS automates process control, reducing human error and improving overall efficiency.

- Safety Enhancement: Alarms and interlocks in the DCS help prevent equipment damage and process upsets, ensuring a safe operating environment.

- Data Analysis: The DCS provides valuable data for process optimization, troubleshooting, and performance monitoring.

3. Explain the importance of maintaining accurate and up-to-date process documentation for a petroleum refinery control panel.

- Safety and Compliance: Accurate documentation ensures that operators have access to the latest information on operating procedures, safety protocols, and emergency response plans.

- Efficient Troubleshooting: Up-to-date documentation provides clear guidance for operators to quickly identify and resolve process issues.

- Knowledge Transfer: Well-maintained documentation facilitates knowledge transfer between operators and shifts, ensuring consistent and safe operations.

- Regulatory Compliance: Documentation provides evidence of compliance with industry standards and regulations, which is essential for audits and inspections.

4. Describe your experience in troubleshooting and resolving process upsets in a petroleum refinery.

- Identify Root Cause: I systematically analyze process parameters, alarm logs, and other data to determine the root cause of upsets.

- Develop Corrective Actions: Based on the root cause analysis, I develop and implement corrective actions to restore process stability and prevent recurrence.

- Communicate with Team: I effectively communicate with other operators, supervisors, and engineers to gather information and coordinate solutions.

- Evaluate and Improve: After resolving upsets, I evaluate the effectiveness of corrective actions and suggest improvements to operating practices to prevent similar issues in the future.

5. How do you handle multiple tasks and prioritize them effectively in a time-sensitive environment?

- Assess Urgency: I quickly assess the criticality of tasks and prioritize them based on their potential impact on process safety and efficiency.

- Time Management: I effectively manage my time by using tools such as checklists and prioritizing tasks based on deadlines and importance.

- Delegation: When appropriate, I delegate tasks to other operators or team members to ensure timely completion without compromising safety or quality.

- Communication: I clearly communicate my priorities and expectations to other team members to ensure alignment and avoid confusion.

6. Explain the principles of preventive maintenance and how you apply them in a petroleum refinery control panel.

- Regular Inspections: I adhere to a schedule of regular inspections to identify potential issues and address them before they become major problems.

- Equipment Calibration: I ensure that all instruments and devices are regularly calibrated to maintain accuracy and reliability.

- Lubrication and Cleaning: I follow lubrication and cleaning schedules to prevent equipment wear and tear and extend its lifespan.

- Record Keeping: I meticulously document all maintenance activities, including dates, observations, and actions taken, to track equipment history and identify trends.

- Continuous Improvement: I actively participate in developing and implementing preventive maintenance strategies to enhance efficiency and reduce downtime.

7. Describe your understanding of the hazards and risks associated with working in a petroleum refinery, and how you mitigate them.

- Fire and Explosion: I am aware of the potential for fires and explosions and adhere to strict safety protocols, including proper handling of flammable liquids and gases.

- Toxic Substances: I understand the hazards of exposure to toxic substances and wear appropriate protective gear, follow established procedures, and maintain a clean work area.

- Confined Spaces: I am trained in confined space entry procedures and take necessary precautions to ensure my safety when working in enclosed areas.

- Electrical Hazards: I recognize the risks of electrical hazards and follow electrical safety protocols, including proper lockout/tagout procedures.

8. Explain the importance of teamwork and communication in the role of a petroleum refinery control panel operator.

- Collaboration: I effectively collaborate with other operators, engineers, and supervisors to ensure smooth and safe operations.

- Communication: I clearly and concisely communicate process information and any issues or concerns to the team.

- Situational Awareness: I maintain situational awareness by sharing information with the team, allowing for a coordinated response to process changes or emergencies.

- Conflict Resolution: I participate in conflict resolution and find mutually acceptable solutions, maintaining a positive and productive work environment.

9. Describe your experience in using software and tools for process monitoring and control in a petroleum refinery.

- DCS/SCADA Systems: I am proficient in operating and monitoring distributed control systems (DCS) and supervisory control and data acquisition (SCADA) systems.

- Process Simulation Software: I have experience using process simulation software to analyze process performance and optimize operating parameters.

- Data Analytics Tools: I utilize data analytics tools to identify trends, detect anomalies, and make data-driven decisions.

- Maintenance Management Software: I am familiar with maintenance management software used to track equipment maintenance history and schedule preventive maintenance tasks.

10. How do you stay up-to-date with the latest industry practices and technological advancements in petroleum refining?

- Training and Development: I actively participate in training programs and workshops to enhance my knowledge and skills.

- Industry Publications: I read industry publications and attend conferences to stay informed about best practices and new technologies.

- Networking: I connect with other professionals in the field to exchange ideas and learn about innovative approaches.

- Research and Development: I engage in research and development activities to explore new technologies and explore their potential impact on refining operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Petroleum Refinery Control Panel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Petroleum Refinery Control Panel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Petroleum Refinery Control Panel Operators are responsible for monitoring and controlling the operations of a petroleum refinery. They use control panels to adjust the flow of crude oil and other materials through the refinery, and to make sure that the refinery is operating safely and efficiently. Key job responsibilities include:

1. Monitoring and Controlling Refinery Operations

Control panel operators use a variety of instruments to monitor the flow of crude oil and other materials through the refinery. They also use control panels to adjust the flow of materials, and to make sure that the refinery is operating safely and efficiently.

- Monitor the flow of crude oil and other materials through the refinery.

- Adjust the flow of materials to optimize the efficiency of the refinery.

- Make sure that the refinery is operating safely and efficiently.

2. Troubleshooting and Repairing Equipment

Control panel operators are responsible for troubleshooting and repairing equipment in the refinery. They use a variety of tools and techniques to identify and fix problems.

- Troubleshoot and repair equipment in the refinery.

- Use a variety of tools and techniques to identify and fix problems.

3. Maintaining Records

Control panel operators are responsible for maintaining records of the refinery’s operations. These records are used to track the flow of materials through the refinery, and to identify any problems that may occur.

- Maintain records of the refinery’s operations.

- Track the flow of materials through the refinery.

- Identify any problems that may occur.

4. Communicating with Other Employees

Control panel operators work closely with other employees in the refinery. They communicate with other operators, supervisors, and engineers to ensure that the refinery is operating safely and efficiently.

- Communicate with other employees in the refinery.

- Work closely with other operators, supervisors, and engineers

Interview Tips

Preparing for an interview for a Petroleum Refinery Control Panel Operator position can be a daunting task. However, by following a few simple tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. By practicing your answers to these questions, you can increase your confidence and your chances of success.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be Prepared to Talk About Your Experience

In your interview, you will be asked about your experience. Be prepared to talk about your experience in a clear and concise way. Highlight your skills and accomplishments, and be sure to relate them to the requirements of the position.

- Use the STAR method to answer interview questions.

- Situation: Describe the situation you were in.

- Task: Describe the task you were responsible for.

- Action: Describe the actions you took.

- Result: Describe the results of your actions.

4. Be Yourself

The most important thing you can do in an interview is to be yourself. Be honest about your skills and your experience, and let the interviewer get to know the real you.

- Don’t try to be someone you’re not.

- Be confident in your abilities.

- Be yourself and let the interviewer get to know the real you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Petroleum Refinery Control Panel Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!