Are you gearing up for a career in Petroleum Refinery Laborer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Petroleum Refinery Laborer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

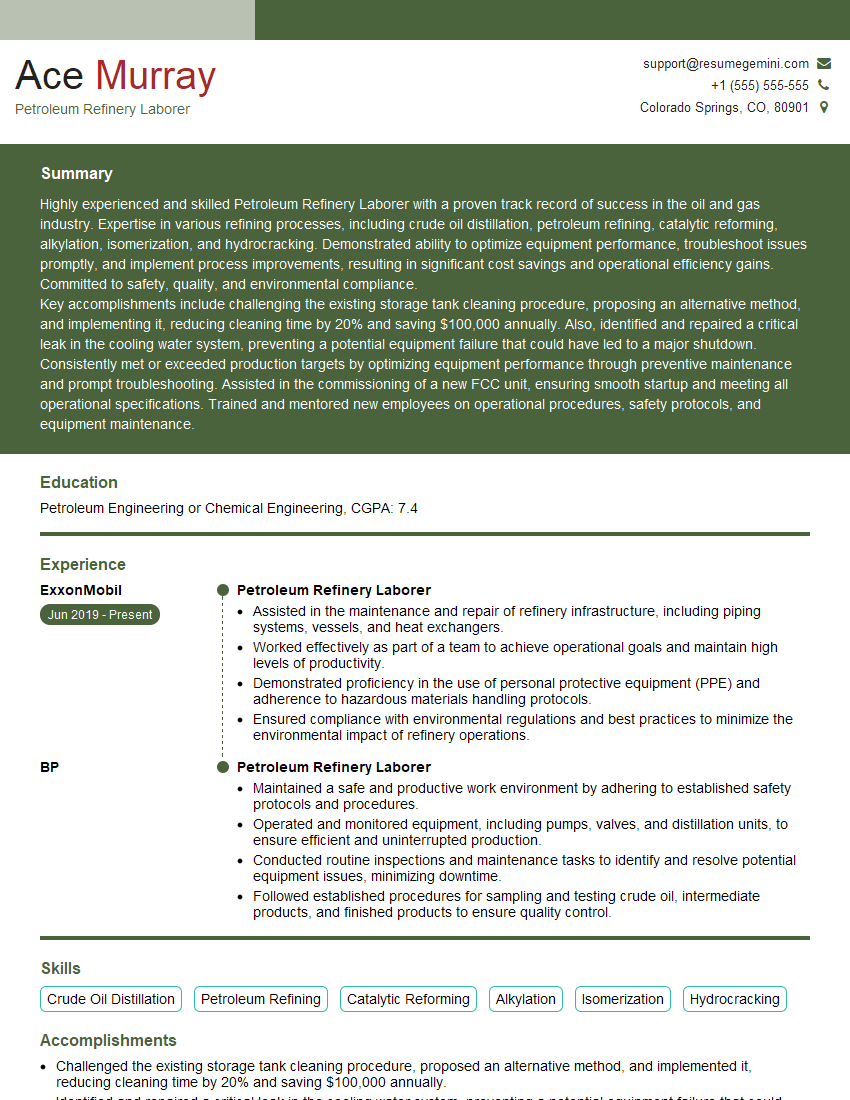

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Petroleum Refinery Laborer

1. What are the different types of crude oil?

- Light crude oil: This type of crude oil is low in density and has a high API gravity. It is easy to refine and produces a high yield of gasoline and other light products.

- Medium crude oil: This type of crude oil has a density between light and heavy crude oil and an API gravity between 22 and 30. It is more difficult to refine than light crude oil but produces a good yield of gasoline and other products.

- Heavy crude oil: This type of crude oil is high in density and has a low API gravity. It is difficult to refine and produces a low yield of gasoline and other light products. However, it can be used to produce heavy fuel oil and other products.

2. What are the main components of crude oil?

- Hydrocarbons: These are the main components of crude oil and are made up of hydrogen and carbon atoms. They can be either aliphatic (straight-chain or branched-chain) or aromatic (ring-shaped).

- Sulfur: This is a common impurity in crude oil and can be present in various forms, such as hydrogen sulfide, organic sulfur compounds, and elemental sulfur.

- Nitrogen: This is another common impurity in crude oil and can be present in various forms, such as ammonia, organic nitrogen compounds, and elemental nitrogen.

- Oxygen: This is a less common impurity in crude oil and can be present in various forms, such as water, organic oxygen compounds, and elemental oxygen.

3. What is the process of fractional distillation?

- Fractional distillation is a process used to separate the different components of crude oil based on their boiling points. The crude oil is heated to a high temperature and then passed through a distillation column. The components with the lowest boiling points, such as methane and ethane, vaporize and rise to the top of the column. The components with the highest boiling points, such as heavy fuel oil, remain at the bottom of the column.

- The different components of crude oil are then collected and stored in separate tanks.

4. What are the different types of petroleum products?

- Gasoline: This is the most common petroleum product and is used to power cars, trucks, and other vehicles.

- Diesel fuel: This is used to power trucks, buses, and other heavy vehicles.

- Jet fuel: This is used to power airplanes.

- Heating oil: This is used to heat homes and businesses.

- Lubricants: These are used to reduce friction between moving parts in engines and other machinery.

- Asphalt: This is used to pave roads and parking lots.

5. What are the safety precautions that must be taken when working in a petroleum refinery?

- Always wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, gloves, and a respirator.

- Be aware of the potential hazards in the area, such as flammable liquids, gases, and equipment.

- Follow all safety procedures and instructions, and never take shortcuts.

- Report any unsafe conditions or practices to your supervisor immediately.

6. What are the different types of maintenance tasks that are performed in a petroleum refinery?

- Preventive maintenance: This is performed on a regular schedule to prevent equipment failures and keep the refinery running smoothly.

- Corrective maintenance: This is performed to repair equipment that has failed or is malfunctioning.

- Predictive maintenance: This is performed to identify potential equipment problems before they occur and to prevent them from causing downtime.

7. What are the different types of tools and equipment that are used in a petroleum refinery?

- Hand tools: These include tools such as wrenches, screwdrivers, hammers, and pliers.

- Power tools: These include tools such as drills, grinders, and saws.

- Heavy equipment: This includes equipment such as cranes, forklifts, and bulldozers.

- Specialized tools: These include tools that are designed specifically for use in a petroleum refinery, such as distillation columns.

8. What are the different types of jobs that are available in a petroleum refinery?

- Operators: These are responsible for operating the equipment in the refinery.

- Maintenance technicians: These are responsible for maintaining and repairing the equipment in the refinery.

- Laboratory technicians: These are responsible for testing the products and materials used in the refinery.

- Engineers: These are responsible for designing and improving the processes used in the refinery.

- Managers: These are responsible for overseeing the operations of the refinery.

9. What are the different types of training that are required to work in a petroleum refinery?

- On-the-job training: This is the most common type of training and is provided by the employer.

- Classroom training: This type of training is typically provided by a community college or technical school.

- Online training: This type of training is becoming increasingly popular and allows employees to learn at their own pace.

10. What are the different types of certifications that are available to petroleum refinery workers?

- API 510: This certification is for inspectors of pressure vessels and piping systems.

- API 570: This certification is for inspectors of rotating machinery.

- API 580: This certification is for inspectors of storage tanks.

- API 653: This certification is for inspectors of aboveground storage tanks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Petroleum Refinery Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Petroleum Refinery Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Petroleum Refinery Laborers play a crucial role in the day-to-day operations of petroleum refineries. They are responsible for a wide range of tasks that ensure the smooth functioning of these complex facilities.

1. Maintenance and Repair

Refinery Laborers perform routine maintenance and repair tasks on various equipment and machinery, such as pumps, valves, pipelines, and storage tanks. They check for leaks, corrosion, and other issues, and take prompt action to resolve them.

- Inspect and monitor equipment for signs of wear and tear

- Perform preventative maintenance and repairs as needed

2. Operation of Equipment

Laborers may operate specialized equipment, such as cranes, forklifts, and heavy machinery, to move materials and perform tasks within the refinery. They follow operating procedures and ensure safety guidelines are adhered to.

- Operate cranes to load and unload materials

- Use forklifts to move heavy equipment and supplies

3. Material Handling

Refinery Laborers handle various materials, including crude oil, refined products, chemicals, and waste. They load and unload materials from trucks, railcars, and storage tanks, and transport them to designated areas within the refinery.

- Load and unload materials using forklifts, cranes, and other equipment

- Transport materials to and from designated areas

4. Cleaning and Sanitation

To maintain a safe and hygienic work environment, Refinery Laborers perform cleaning and sanitation tasks. They clean equipment, work areas, and storage tanks, and dispose of waste materials according to established procedures.

- Clean and sanitize equipment, work areas, and storage tanks

- Dispose of waste materials according to established procedures

Interview Tips

To ace a job interview for a Petroleum Refinery Laborer position, candidates should prepare thoroughly and highlight their relevant skills and experience.

1. Research the Company and Industry

Demonstrate your interest and understanding of the company and the petroleum refining industry. Research the company’s history, operations, and recent news to show you’ve taken the time to learn about their business. Familiarize yourself with the industry’s trends, challenges, and safety regulations.

- Visit the company’s website and social media pages

- Read industry news and articles

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Prepare specific examples of situations where you’ve demonstrated your ability to perform tasks such as equipment operation, material handling, and maintenance. Quantify your accomplishments whenever possible.

- Mention any experience working in a refinery or similar industrial setting

- Highlight your skills in operating heavy machinery and equipment

3. Emphasize Safety Consciousness

Safety is paramount in the petroleum refining industry. Demonstrate your commitment to following safety procedures and maintaining a safe work environment. Share examples of your adherence to safety regulations and your understanding of the potential hazards associated with the job.

- Discuss your knowledge of safety protocols and regulations

- Provide examples of how you’ve prioritized safety in your previous roles

4. Prepare for Physical Demands

Petroleum Refinery Laborer positions can involve physically demanding tasks. Be prepared to discuss your physical capabilities and your ability to work in a physically strenuous environment. Highlight any experience you have with manual labor or physically demanding activities.

- Describe your physical fitness and ability to perform heavy lifting and manual tasks

- Mention any experience working in a fast-paced or demanding environment

Next Step:

Now that you’re armed with the knowledge of Petroleum Refinery Laborer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Petroleum Refinery Laborer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini