Are you gearing up for an interview for a Pharmaceutical Manufacturing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pharmaceutical Manufacturing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

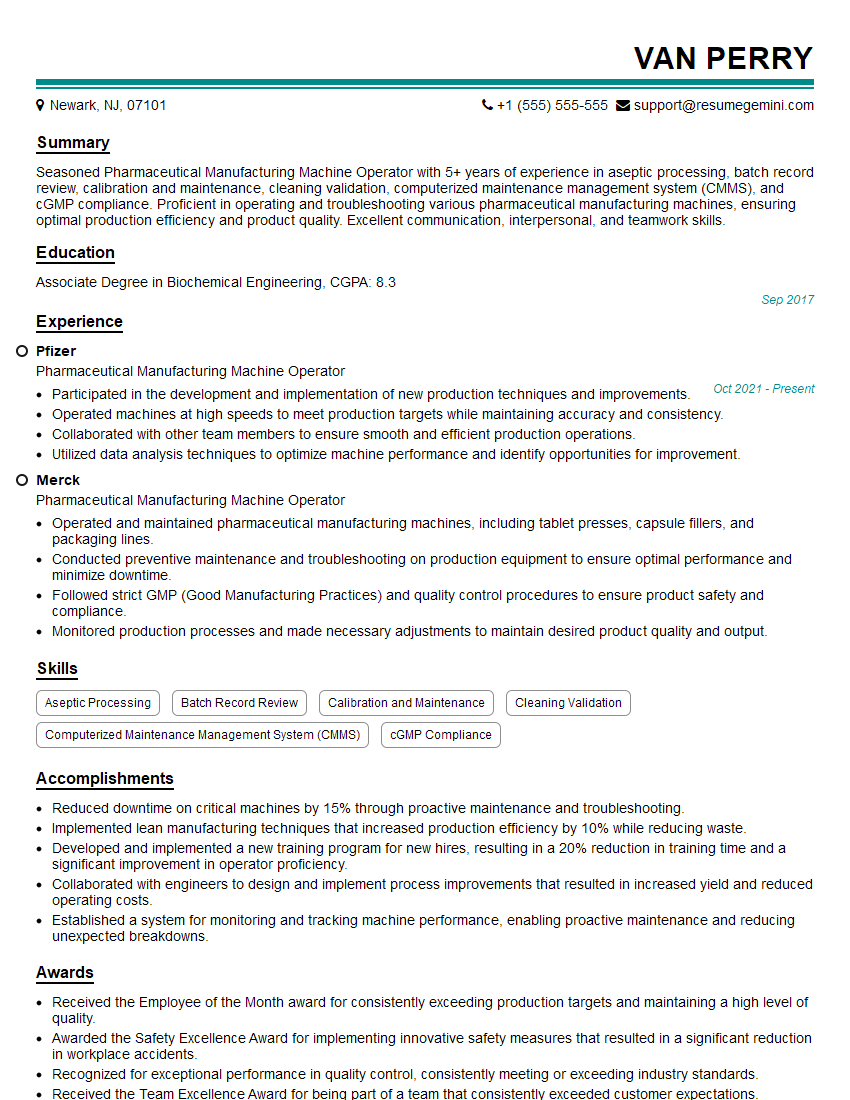

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pharmaceutical Manufacturing Machine Operator

1. Explain the process of tablet manufacturing on a rotary tablet press.

The process of tablet manufacturing on a rotary tablet press involves several key steps:

- Blending: Raw materials, including active pharmaceutical ingredients (APIs) and excipients, are blended to ensure uniform distribution.

- Granulation: The blended materials are moistened and granulated to form small, porous granules that improve flowability and compressibility.

- Drying: The granules are dried to remove moisture and achieve the desired particle size and moisture content.

- Lubrication: Lubricants are added to the granules to reduce friction during compression and improve tablet ejection from the press.

- Compression: The lubricated granules are fed into the rotary tablet press, where they are compressed using punches and dies to form tablets.

- Coating: Tablets may be coated with various materials to improve taste, appearance, and solubility.

2. What are the critical parameters that need to be monitored and controlled during tablet manufacturing?

Quality Control Parameters

- API content

- Tablet weight and hardness

- Tablet dimensions

- Disintegration time

- Dissolution rate

Process Control Parameters

- Granule size and moisture content

- Lubricant concentration

- Compression force and dwell time

- Coating thickness and uniformity

3. Describe the operation and maintenance of a blister packaging machine.

A blister packaging machine forms and seals blisters from thermoplastic film, which are then filled with tablets or capsules. Here’s a brief description of its operation:

- The film is heated and fed into the machine, where it is formed into blisters.

- The product is dispensed into the blisters.

- A backing foil is fed into the machine and sealed to the blisters, forming the final package.

Maintenance tasks include:

- Regular cleaning and lubrication

- Checking and replacing worn or damaged parts

- Calibrating the machine to ensure accurate product placement and sealing

4. How do you ensure sterility in pharmaceutical manufacturing?

Ensuring sterility in pharmaceutical manufacturing is crucial to prevent contamination and protect patient safety. Here are key measures:

- Sterile Environment: Cleanrooms or isolators are used to minimize airborne contamination.

- Sterilization Equipment: Autoclaves, dry heat ovens, and gamma irradiation are employed to sterilize equipment and materials.

- Aseptic Techniques: Personnel follow strict aseptic procedures to minimize contamination during handling.

- Quality Control: Sterility testing is conducted to ensure the absence of microorganisms.

- Environmental Monitoring: Regular monitoring of the environment for microbial contamination helps detect any potential issues.

5. Explain the principles of Good Manufacturing Practices (GMP) in pharmaceutical manufacturing.

Good Manufacturing Practices (GMP) are regulations that set quality standards for the production of pharmaceuticals. Key principles include:

- Documentation: Detailed documentation of all processes, including standard operating procedures (SOPs).

- Equipment Validation: Verifying that equipment meets specifications and operates consistently.

- Quality Control: Implementing quality checks at various stages of production to ensure product quality.

- Employee Training: Providing proper training to employees to ensure they understand and adhere to GMP.

- Environmental Control: Maintaining a clean and controlled production environment.

6. How do you handle equipment breakdowns or malfunctions?

When equipment breaks down or malfunctions, it is important to respond promptly and effectively to minimize downtime and ensure product quality. The following steps are crucial:

- Safety First: Ensure the safety of personnel and isolate the equipment if necessary.

- Troubleshooting: Identify the root cause of the issue using diagnostic tools or technical manuals.

- Repair or Replacement: Perform necessary repairs or replace damaged parts to restore functionality.

- Documentation: Record the breakdown, troubleshooting process, and resolution for future reference.

- Preventive Maintenance: Regularly schedule preventive maintenance to minimize equipment breakdowns.

7. Describe your experience with troubleshooting pharmaceutical manufacturing equipment.

I have extensive experience in troubleshooting various pharmaceutical manufacturing equipment, including tablet presses, blister packaging machines, and autoclaves. I use a methodical approach, relying on technical manuals, diagnostic tools, and my knowledge of equipment operation to identify and resolve issues efficiently. I prioritize safety and follow established protocols to ensure that the equipment is repaired and calibrated to meet specifications.

8. How do you stay up-to-date with advancements in pharmaceutical manufacturing technology?

To stay up-to-date with advancements in pharmaceutical manufacturing technology, I actively engage in industry events, seminars, and webinars. I read technical journals and subscribe to industry publications to gain insights into emerging technologies and best practices. I also participate in online forums and connect with experts in the field through LinkedIn or professional organizations to exchange ideas and learn about new developments.

9. What is your understanding of process validation in pharmaceutical manufacturing?

Process validation in pharmaceutical manufacturing is a critical step to ensure the consistent production of high-quality products. It involves verifying that each step in the manufacturing process is repeatable, reproducible, and meets predefined specifications. I have participated in process validation projects, which include establishing validation protocols, conducting qualification tests, and analyzing data to demonstrate that the process is operating within acceptable limits. I understand the importance of documentation, risk assessment, and continuous monitoring to maintain the validated state of pharmaceutical manufacturing processes.

10. How do you prioritize tasks and manage multiple responsibilities in a fast-paced pharmaceutical manufacturing environment?

Prioritizing tasks and managing multiple responsibilities in a fast-paced pharmaceutical manufacturing environment is crucial for maintaining efficiency and productivity. I use a combination of planning, organization, and effective communication to stay on top of my responsibilities. I start by creating a daily or weekly schedule, prioritizing tasks based on urgency and importance. I also break down large projects into smaller, manageable chunks to avoid feeling overwhelmed. I actively seek support and delegate tasks to colleagues when necessary to ensure timely completion without compromising quality. Open communication with my supervisor and team members helps me stay informed about changes in priorities and allows for timely adjustments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pharmaceutical Manufacturing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pharmaceutical Manufacturing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pharmaceutical Manufacturing Machine Operators are responsible for operating and maintaining a variety of machines used in the manufacturing of pharmaceutical products. Their key responsibilities include:

1. Operating and Maintaining Pharmaceutical Manufacturing Machines

Operators set up, operate, and maintain a range of machines used in the production of pharmaceuticals, including:

- Tabletting machines: These machines compress powder into tablets.

- Capsule filling machines: These machines fill capsules with powder or liquid.

- Coating machines: These machines coat tablets or capsules with a protective layer.

- Packaging machines: These machines package pharmaceuticals into bottles, vials, or other containers.

2. Monitoring Production Processes

Operators monitor the production process to ensure that machines are operating correctly and that products are being produced according to specifications. They may also make adjustments to machines as needed to optimize production.

- Inspecting raw materials and finished products for quality.

- Monitoring gauges and instruments to ensure that machines are operating within acceptable limits.

- Troubleshooting and resolving problems with machines.

3. Cleaning and Sanitizing Equipment

Operators clean and sanitize equipment to maintain a sterile environment and prevent contamination of products. They may also perform routine maintenance on equipment to keep it in good working order.

- Cleaning and sanitizing work areas, equipment, and tools.

- Performing preventive maintenance on equipment.

- Following established cleaning and sanitation procedures.

4. Maintaining a Safe Work Environment

Operators follow safety procedures to protect themselves and others from hazards in the workplace. They may also participate in safety training programs to stay up-to-date on the latest safety best practices.

- Following established safety procedures.

- Wearing appropriate personal protective equipment (PPE).

- Reporting any safety concerns or hazards to supervisors.

Interview Tips

To ace an interview for a Pharmaceutical Manufacturing Machine Operator position, it’s important to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips for success:

1. Research the Company and Position

Learn about the company’s history, products, and culture. This will help you understand the company’s needs and how your skills and experience can benefit the organization.

2. Practice Common Interview Questions

There are several common interview questions that you’re likely to encounter, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions concisely and professionally.

3. Highlight Your Skills and Experience

Be sure to highlight your relevant skills and experience during the interview. This includes your ability to operate and maintain pharmaceutical manufacturing machines, your knowledge of GMP (Good Manufacturing Practices), and your safety record.

4. Be Enthusiastic and Positive

Enthusiasm and a positive attitude can go a long way in an interview. Show the interviewer that you’re excited about the opportunity to work for the company and that you’re confident in your abilities.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you’re interested in the opportunity and that you want to learn more about the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pharmaceutical Manufacturing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!