Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Phosphoric Acid Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

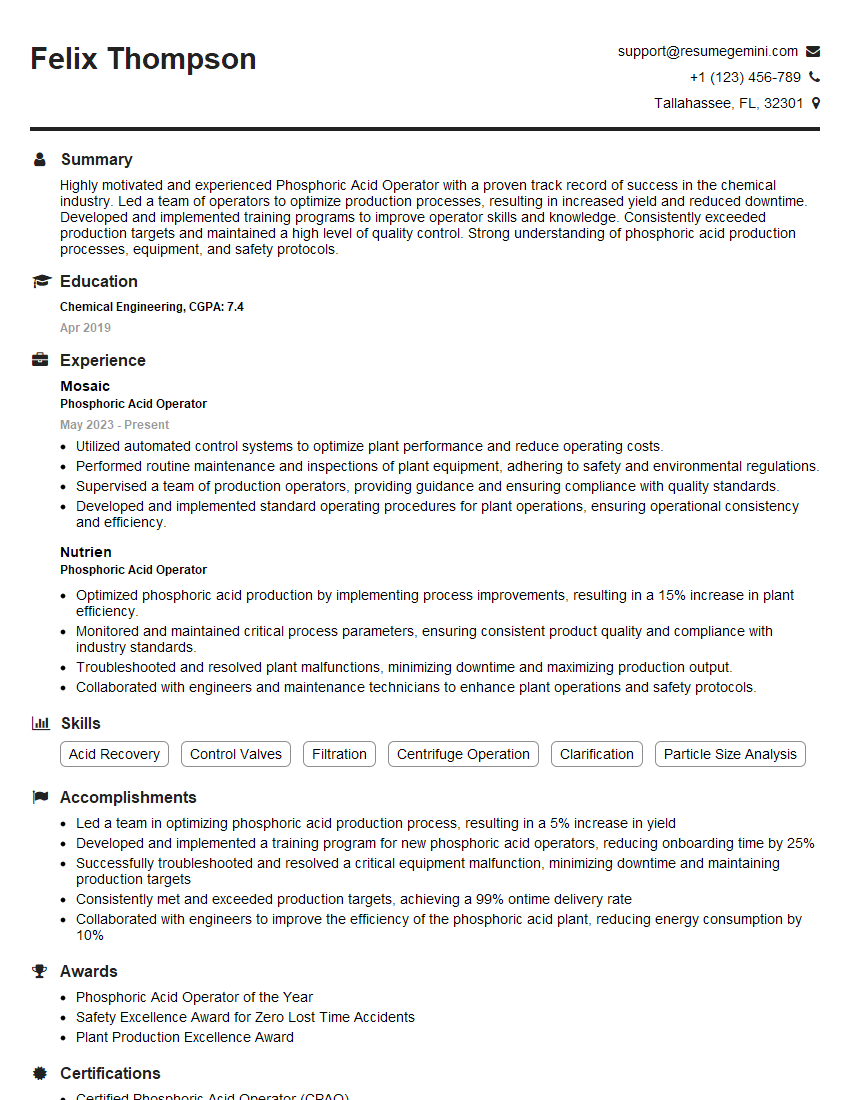

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Phosphoric Acid Operator

1. How do you ensure the quality of the phosphoric acid produced?

To ensure the quality of the phosphoric acid produced, I follow several key procedures:

- Regularly monitoring process parameters: I closely monitor various process parameters such as temperature, pressure, and flow rates to ensure they are within the desired ranges.

- Sampling and testing: I take representative samples of the phosphoric acid at different stages of the production process and conduct various tests to determine its quality attributes, including purity, acidity, and impurities.

- Adhering to quality standards: I strictly adhere to established quality standards and specifications for phosphoric acid production. This involves following prescribed procedures, using calibrated equipment, and maintaining accurate records.

2. Describe the safety precautions you observe while operating a phosphoric acid plant.

Proper Personal Protective Equipment (PPE)

- Wear appropriate PPE, including chemical-resistant gloves, goggles, a respirator, and protective clothing, to minimize exposure to hazardous chemicals.

Handling Chemicals Safely

- Follow established protocols for handling and storing phosphoric acid and other chemicals.

- Use designated areas for chemical storage and ensure proper ventilation and containment measures are in place.

Emergency Preparedness

- Be familiar with emergency procedures and evacuation routes.

- Know the location and proper use of safety equipment, such as fire extinguishers and eyewash stations.

3. How do you handle process deviations in the phosphoric acid production process?

When process deviations occur, I respond promptly to minimize their impact on production and ensure the quality of the phosphoric acid:

- Identifying the deviation: I use monitoring systems and instrumentation to detect process deviations and determine their root cause.

- Taking corrective actions: Based on my understanding of the process and my knowledge of the equipment, I take appropriate corrective actions to bring the process back to normal operating conditions.

- Documenting the deviation and corrective actions: I thoroughly document the process deviation, its cause, and the actions taken to correct it. This information is essential for future analysis and improvement.

4. Explain the role of the reactor in the phosphoric acid production process.

The reactor plays a crucial role in the phosphoric acid production process by facilitating the chemical reaction between phosphate rock and sulfuric acid:

- Providing optimal conditions: The reactor provides the necessary temperature, pressure, and agitation conditions for the reaction to take place efficiently.

- Controlling the reaction rate: By regulating the operating parameters of the reactor, I can control the rate of the reaction and ensure the desired conversion of phosphate rock to phosphoric acid.

- Maintaining product quality: The reactor design and operating conditions contribute to the quality of the phosphoric acid produced by minimizing impurities and unwanted byproducts.

5. How do you optimize the efficiency of the phosphoric acid production process?

To optimize the efficiency of the phosphoric acid production process, I focus on several key areas:

- Process optimization: I review the process parameters and make adjustments to improve efficiency, such as optimizing the reactor conditions, minimizing energy consumption, and reducing waste.

- Equipment maintenance: I ensure that all equipment is properly maintained and calibrated to minimize downtime and maximize production capacity.

- Operator training: I provide training to operators to enhance their skills and knowledge, enabling them to operate the plant efficiently and safely.

6. Describe the different types of impurities commonly found in phosphoric acid and how you manage them.

Common impurities found in phosphoric acid include:

- Fluoride: I use fluoride removal systems to reduce fluoride levels to acceptable limits.

- Sulfuric acid: I optimize the reaction conditions and use purification techniques to minimize residual sulfuric acid.

- Heavy metals: I employ ion exchange or precipitation methods to remove heavy metals and meet environmental regulations.

7. How do you ensure the safety of the phosphoric acid storage and handling facilities?

To ensure the safety of the phosphoric acid storage and handling facilities, I adhere to the following measures:

- Proper storage: Phosphoric acid is stored in designated, corrosion-resistant tanks equipped with appropriate containment systems.

- Safe handling: Operators are trained in safe handling procedures, including the use of personal protective equipment and spill response protocols.

- Regular inspections: I conduct regular inspections of the storage and handling facilities to identify potential hazards and ensure compliance with safety regulations.

8. Explain the principles of the evaporation and crystallization process in phosphoric acid production.

Evaporation

- Phosphoric acid is concentrated by removing water through evaporation.

- Evaporation is achieved using multiple-effect evaporators or vacuum evaporators.

Crystallization

- Concentrated phosphoric acid is cooled to induce crystallization.

- Crystals are separated from the mother liquor through filtration or centrifugation.

9. How do you troubleshoot common problems encountered in phosphoric acid production?

Common problems and my troubleshooting approach include:

- Low acid concentration: I check the reactor conditions, feed rates, and efficiency of the evaporation system.

- Impurities: I analyze the acid composition and implement appropriate removal techniques.

- Equipment malfunctions: I conduct inspections, diagnose the issue, and coordinate repairs or replacements.

10. Describe the environmental regulations and best practices related to phosphoric acid production.

- Air pollution control: I ensure compliance with emission regulations by implementing dust collectors and scrubbers.

- Water management: I optimize water usage, treat wastewater, and minimize discharges.

- Waste disposal: I follow proper disposal procedures for hazardous waste and byproducts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Phosphoric Acid Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Phosphoric Acid Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Monitor and Control Phosphoric Acid Production Process

Phosphoric Acid Operators are accountable for observing and regulating the manufacturing process of phosphoric acid. This entails overseeing the feeding of raw materials, monitoring equipment performance, and adjusting process parameters to ensure efficient and safe production. They must be vigilant in identifying and addressing any deviations from standard operating procedures to maintain optimal production levels and product quality.

2. Ensure Quality Control and Compliance

Maintaining the quality of phosphoric acid is a crucial responsibility for Operators. They conduct regular tests and inspections to assess the purity and concentration of the acid, ensuring adherence to established standards. Additionally, they are responsible for implementing quality control measures throughout the production process, minimizing contamination and ensuring compliance with regulatory requirements.

3. Operate and Maintain Process Equipment

Phosphoric Acid Operators are proficient in operating and maintaining the equipment used in the production process. They conduct routine checks and calibrations to ensure equipment is functioning optimally. They also perform minor repairs and troubleshoot issues, minimizing downtime and maximizing productivity.

4. Collaborate with Team and Supervise Subordinates

Collaboration and communication are essential for Phosphoric Acid Operators. They work closely with other operators, engineers, and supervisors to ensure seamless production and resolve any challenges that may arise. Additionally, they may supervise subordinate staff, providing guidance and support while maintaining a safe and efficient work environment.

Interview Tips

Preparing thoroughly for an interview is vital for any job applicant. Here are some specific tips and strategies to help candidates excel in an interview for a Phosphoric Acid Operator position:

1. Research the Company and Position

A well-informed candidate is a confident candidate. Before the interview, thoroughly research the company’s history, values, and the specific responsibilities of the Phosphoric Acid Operator role. This knowledge will enable you to ask insightful questions, demonstrate your understanding of the position, and articulate how your skills align with the company’s needs.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in phosphoric acid production, quality control, and equipment operation. Quantify your accomplishments and provide specific examples of how you contributed to process optimization, quality improvement, and safety initiatives. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide a clear and concise overview of your relevant experiences.

3. Prepare for Technical Questions

Expect to encounter technical questions during the interview. Review fundamental concepts of phosphoric acid production, including the different methods of production, process parameters, and quality control techniques. Anticipate questions related to equipment operation and maintenance, and be prepared to discuss your troubleshooting and problem-solving skills.

4. Demonstrate Safety Awareness

Safety is paramount in the chemical industry. Emphasize your commitment to safety and your understanding of safety protocols and procedures. Highlight your experience in implementing safety measures, conducting risk assessments, and adhering to regulatory requirements. Show that you prioritize the safety of yourself, your colleagues, and the environment.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions that explore the company’s growth plans, sustainability initiatives, and opportunities for professional development. This not only shows your enthusiasm but also allows you to gather additional information about the company culture and future prospects.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Phosphoric Acid Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.