Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Photo Tube Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Photo Tube Assembler so you can tailor your answers to impress potential employers.

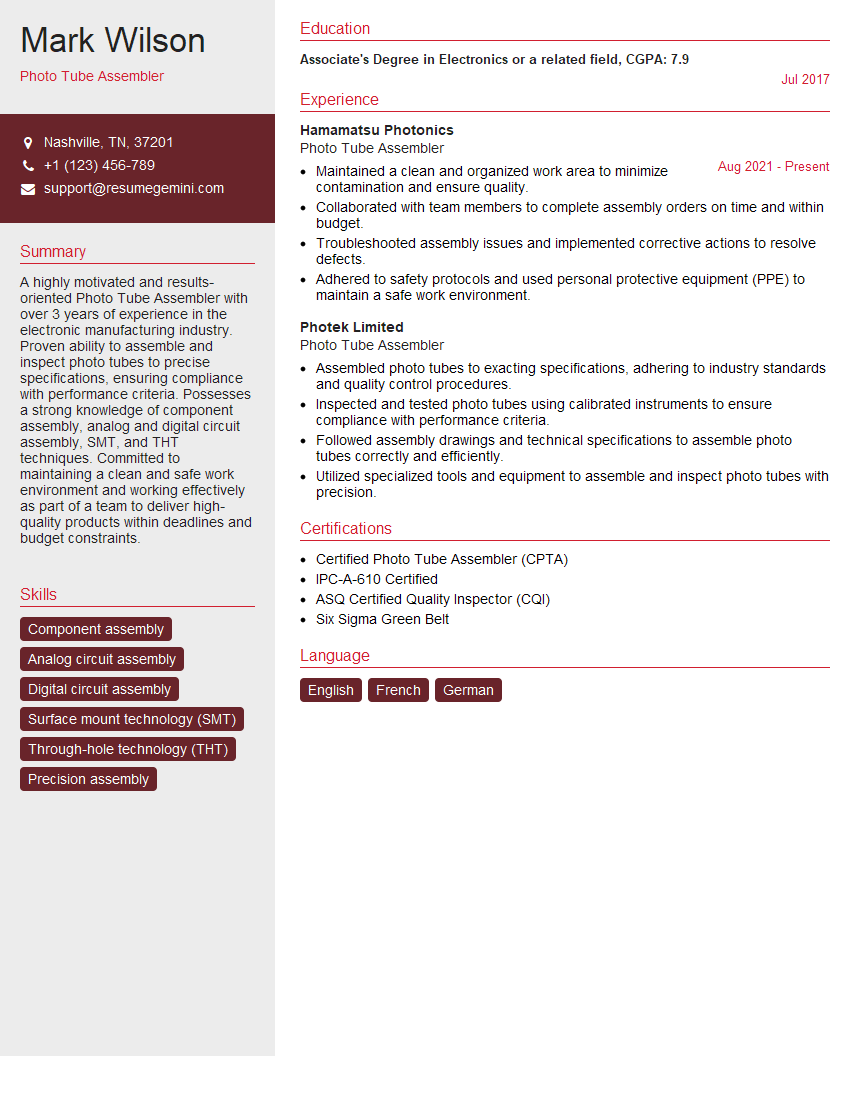

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photo Tube Assembler

1. What are the key steps involved in assembling a phototube?

- Inspecting the components for defects

- Mounting the photocathode to the base

- Installing the anode and focusing electrodes

- Sealing the phototube and testing its performance

2. How do you ensure the cleanliness of the phototube components during assembly?

Cleanroom environment

- Working in a cleanroom with controlled temperature, humidity, and air quality

- Wearing cleanroom garments and gloves to minimize contamination

Component handling

- Using antistatic tools and materials to prevent electrostatic discharge

- Inspecting components under magnification for any imperfections

3. What are the different types of phototubes and what are their applications?

- Vacuum phototubes: Used for detecting low levels of light, such as in photomultipliers and night vision devices

- Gas-filled phototubes: Used for detecting higher levels of light, such as in industrial sensors and flame detectors

- Photomultiplier tubes: Used for amplifying very weak light signals, such as in particle physics and medical imaging

4. Explain the process of photoemission and how it is used in phototubes.

- When light strikes a photocathode, electrons are emitted through a process called photoemission

- The emitted electrons are accelerated towards an anode, creating an electrical current

- The current is amplified and processed to detect the presence and intensity of light

5. What are the factors that affect the sensitivity and response time of a phototube?

-

Sensitivity:

- Material of the photocathode

- Thickness of the photocathode

- Bias voltage applied to the phototube Response time:

- Transit time of electrons from the photocathode to the anode

- Decay time of the photocathode

- Capacitance of the phototube

6. How do you troubleshoot common problems that may occur during phototube assembly?

- Low sensitivity: Check photocathode cleanliness, bias voltage, and photocathode material

- Slow response time: Check transit time, decay time, and capacitance

- Intermittent operation: Check connections, insulation, and mechanical integrity

- Excessive noise: Check grounding, shielding, and component cleanliness

7. What quality control measures do you follow to ensure the reliability of phototubes?

- Component inspection: Verify dimensions, materials, and cleanliness

- Assembly process control: Follow standard procedures and monitor environmental conditions

- Performance testing: Measure sensitivity, response time, and other key parameters

- Data recording and analysis: Traceability and documentation of all quality data

8. How do you calibrate a phototube and why is it important?

- Use a calibrated light source and known reference values

- Adjust the bias voltage or other parameters to achieve desired sensitivity and response Importance:

- Ensures accurate and consistent performance

- Compensates for variations in components and operating conditions

- Facilitates traceability and quality control

9. What are the safety precautions that must be taken when working with phototubes?

- High voltage: Use proper grounding and insulation techniques

- UV radiation: Shield phototubes from light during handling and storage

- Electrical hazards: Use antistatic materials and follow proper handling procedures

- Glass handling: Handle phototubes with care to avoid breakage

10. How do you stay updated on new developments and best practices in phototube assembly?

- Read industry publications and technical journals

- Attend conferences and training workshops

- Collaborate with colleagues and experts in the field

- Seek feedback and suggestions for continuous improvement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photo Tube Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photo Tube Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Photo Tube Assembler is accountable for assembling and testing photo tubes, ensuring their functionality and adherence to quality standards. The key job responsibilities include:

1. Assembly of Photo Tubes

Assemble photo tubes by aligning and connecting components, such as glass envelopes, electrodes, and lead wires

- Adhere to established assembly procedures and blueprints

- Use precision tools and equipment to handle and manipulate delicate components

2. Testing and Inspection

Conduct rigorous testing to verify the performance and quality of assembled photo tubes

- Operate testing equipment, such as light sources and detectors, to assess tube sensitivity and other parameters

- Inspect tubes for defects, contamination, or imperfections that may affect performance

3. Troubleshooting and Repair

Diagnose and resolve any issues or defects identified during testing

- Identify and rectify assembly errors or component failures

- Collaborate with engineers or technicians to determine root causes and implement corrective actions

4. Production Support

Maintain a clean and organized work environment, ensuring efficient assembly and testing operations

- Identify and requisition necessary materials and supplies

- Assist in the training and onboarding of new employees

Interview Tips

To excel in a Photo Tube Assembler interview, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s background, products, and the specific role to gain insights into their operations and expectations

- Visit the company website, read industry news, and consult LinkedIn to gather information

- Analyze the job description to identify key requirements and responsibilities

2. Highlight Relevant Skills and Experience

During the interview, emphasize your technical skills in photo tube assembly, testing, and troubleshooting

- Quantify your accomplishments and provide specific examples of your contributions

- Demonstrate your understanding of assembly processes, testing methods, and industry standards

3. Be Prepared for Technical Questions

Expect detailed questions about photo tube assembly techniques, testing procedures, and troubleshooting strategies

- Review common assembly and testing protocols

- Practice answering questions about quality control measures and problem-solving approaches

4. Showcase Your Precision and Attention to Detail

Emphasize your meticulous nature and ability to work with precision, as these qualities are crucial for photo tube assembly

- Describe your experience in handling delicate components and maintaining a clean work environment

- Highlight any certifications or training related to precision assembly or quality control

5. Prepare Questions

Ask thoughtful questions to demonstrate your interest in the company and the role

- Inquire about the company’s production goals and quality standards

- Ask about opportunities for professional development and career advancement

Next Step:

Now that you’re armed with the knowledge of Photo Tube Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Photo Tube Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini