Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Photocomposing Perforator Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Photocomposing Perforator Machine Operator so you can tailor your answers to impress potential employers.

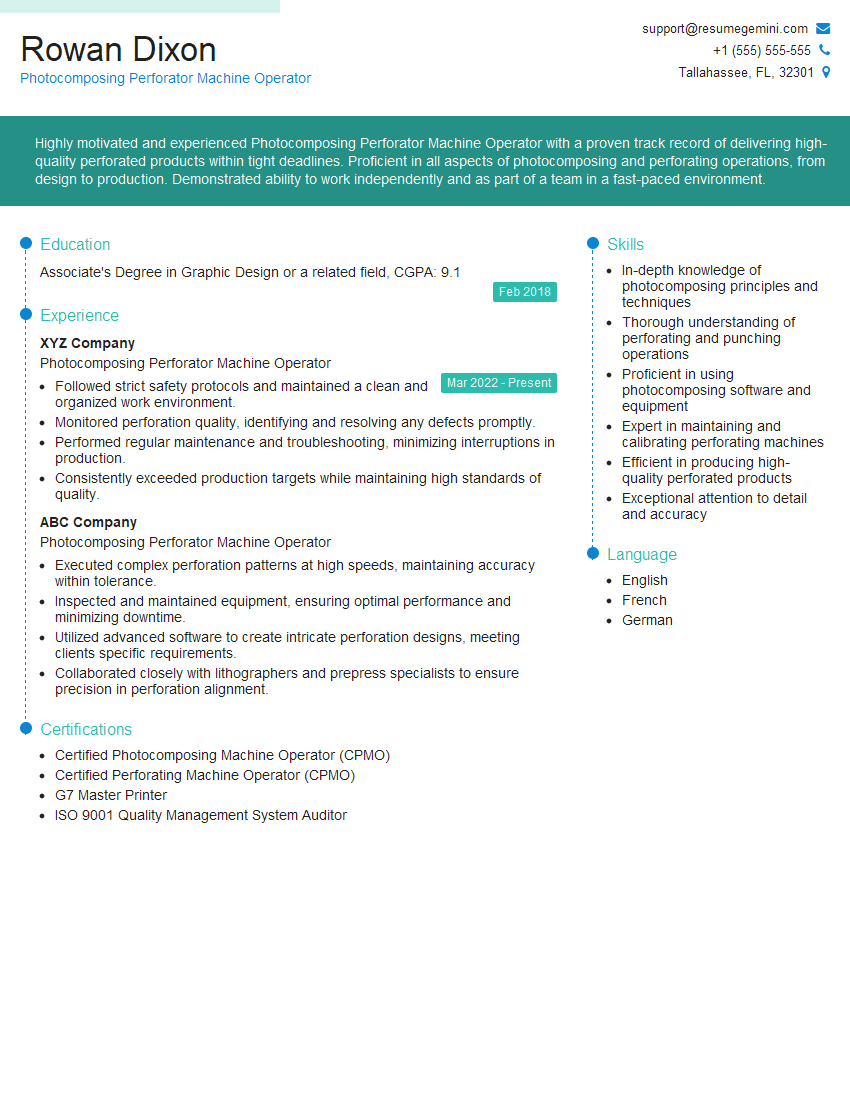

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photocomposing Perforator Machine Operator

1. Describe the key responsibilities of a Photocomposing Perforator Machine Operator?

The key responsibilities of a Photocomposing Perforator Machine Operator include:

- Operating photocomposing perforator machines to produce high-quality printed materials

- Setting up and calibrating machines to ensure optimal performance

- Loading and unloading paper stock, film, and other materials

- Performing quality control checks on finished products

- Maintaining a clean and organized work area

2. What are the different types of photocomposing perforator machines and their applications?

Types of Photocomposing Perforator Machines:

- Flatbed Perforators: Used for perforating large sheets of paper

- Rotary Perforators: Used for high-volume perforation of continuous forms

- Laser Perforators: Used for precise and intricate perforation patterns

Applications:

- Printing and binding of books, magazines, and brochures

- Creation of tickets, coupons, and other perforated materials

- Perforating envelopes and other mailing materials

3. Explain the process of operating a photocomposing perforator machine?

The process of operating a photocomposing perforator machine involves the following steps:

- Setting up the machine with the appropriate paper stock and film

- Calibrating the machine to ensure accurate perforation

- Loading the paper into the machine and starting the perforation process

- Monitoring the machine during operation to ensure optimal performance

- Unloading the perforated paper and inspecting it for quality

4. What are the safety precautions that must be followed while operating a photocomposing perforator machine?

The following safety precautions must be followed while operating a photocomposing perforator machine:

- Wear appropriate safety gear, including gloves and eye protection

- Keep hands away from moving parts

- Do not attempt to clear jams while the machine is running

- Unplug the machine before performing maintenance or repairs

- Follow all manufacturer’s instructions and guidelines

5. What are the common troubleshooting tips for photocomposing perforator machines?

Common troubleshooting tips for photocomposing perforator machines include:

- Checking for paper jams or other obstructions

- Calibrating the machine to ensure accurate perforation

- Replacing worn or damaged parts

- Cleaning the machine regularly to prevent buildup

- Consulting the manufacturer’s manual for specific troubleshooting procedures

6. How do you ensure the quality of finished products produced using a photocomposing perforator machine?

To ensure the quality of finished products, I follow these steps:

- Inspecting paper stock and film for defects before loading

- Calibrating the machine regularly to maintain accuracy

- Monitoring the machine during operation to detect any irregularities

- Performing quality control checks on finished products

- Adjusting the machine settings as needed to optimize performance

7. What are the different types of perforation patterns and their applications?

Types of Perforation Patterns:

- Straight Perforation: Used for easy tearing along a straight line

- Cross Perforation: Used for tearing in two directions

- Stub Perforation: Used for creating perforated stubs on tickets and receipts

Applications:

- Creating tear-off pages in magazines and catalogs

- Perforating tickets and coupons for easy separation

- Creating perforated lines on envelopes for easy opening

8. How do you handle machine breakdowns or malfunctions?

In case of machine breakdowns or malfunctions, I follow these steps:

- Identify the problem and consult the manufacturer’s manual

- If possible, troubleshoot and fix the issue myself

- If the issue cannot be resolved, I contact the maintenance team

- Document the breakdown and any troubleshooting steps taken

- Assist the maintenance team in resolving the issue efficiently

9. Explain how you stay up-to-date with the latest advancements in photocomposing perforation technology?

To stay up-to-date with the latest advancements in photocomposing perforation technology, I:

- Attend industry workshops and conferences

- Read trade publications and online resources

- Network with other professionals in the field

- Explore new products and services offered by machine manufacturers

- Seek opportunities for professional development and training

10. How do you maintain a consistent work speed and quality while operating a photocomposing perforator machine?

To maintain a consistent work speed and quality, I:

- Set realistic production targets

- Optimize machine settings for efficiency and accuracy

- Regularly inspect and calibrate the machine

- Take breaks as needed to avoid fatigue and maintain concentration

- Follow standard operating procedures and best practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photocomposing Perforator Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photocomposing Perforator Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photocomposing Perforator Machine Operators are responsible for creating and modifying printing plates, stencils, and other materials used in printing. They use a variety of machines, including photocomposing machines, perforators, and other equipment.

1. Preparing Materials

Prepare materials for printing, including film, plates, and other materials.

- Inspect materials for defects.

- Cut and align materials to the correct size.

2. Operating Machines

Operate photocomposing and perforating machines to create printing plates, stencils, and other materials.

- Set up machines according to specifications.

- Monitor machines during operation.

3. Inspecting Products

Inspect products for defects and ensure that they meet quality standards.

- Check for smudges, scratches, and other imperfections.

- Make adjustments to machines as needed.

4. Maintaining Equipment

Maintain equipment in good working condition.

- Clean and lubricate machines.

- Perform minor repairs.

Interview Tips

To ace an interview for a Photocomposing Perforator Machine Operator position, candidates should be prepared to demonstrate their skills and knowledge in the following areas:

1. Technical Skills

Candidates should have a strong understanding of the principles of photocomposing and perforating. They should also be proficient in the operation of photocomposing and perforating machines.

- Be able to explain the different types of photocomposing and perforating machines.

- Describe the process of creating a printing plate or stencil.

2. Attention to Detail

Candidates must have a keen eye for detail and be able to identify and correct errors in their work.

- Describe a time when you had to identify and correct an error in your work.

- Explain how you would ensure that your work met the highest quality standards.

3. Problem-Solving Skills

Candidates should be able to solve problems quickly and efficiently.

- Describe a time when you had to solve a problem with a photocomposing or perforating machine.

- Explain how you would troubleshoot a problem with a printing plate or stencil.

4. Interpersonal Skills

Candidates should be able to work independently and as part of a team. They should also be able to communicate effectively with others.

- Describe a time when you had to work independently to complete a project.

- Explain how you would work as part of a team to complete a project.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Photocomposing Perforator Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Photocomposing Perforator Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.