Are you gearing up for an interview for a Photocopying Equipment Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Photocopying Equipment Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

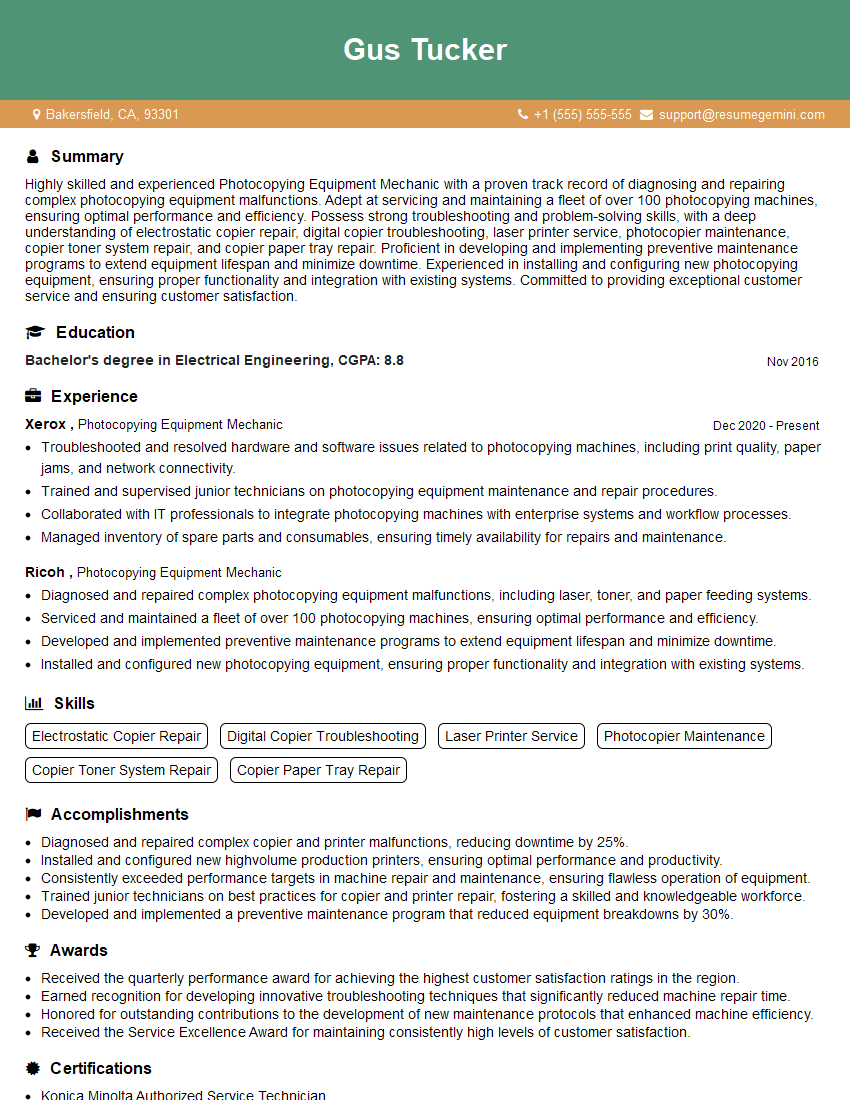

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photocopying Equipment Mechanic

1. Explain the process of troubleshooting a photocopying machine?

- Gather information from the user about the problem.

- Inspect the machine for any obvious problems.

- Run diagnostic tests to identify the source of the problem.

- Repair or replace the faulty components.

- Test the machine to ensure the problem has been resolved.

2. What are the common maintenance procedures for photocopying machines?

Daily maintenance:

- Cleaning the exterior of the machine.

- Removing any jammed paper.

- Checking the toner levels.

Weekly maintenance:

- Cleaning the interior of the machine.

- Lubricating the moving parts.

- Checking the print quality.

Monthly maintenance:

- Replacing the toner cartridges.

- Cleaning the fuser unit.

- Checking the electrical connections.

3. What are the different types of copying processes?

- Analog copying: Uses a light source to create an image on a photosensitive drum, which then transfers the image to paper.

- Digital copying: Uses a digital scanner to create a digital image of the original document, which is then printed onto paper.

- Multifunction copying: Combines the functions of copying, printing, scanning, and faxing in a single machine.

4. What are the safety precautions that should be taken when working on photocopying machines?

- Unplug the machine from the power source before performing any maintenance.

- Avoid touching the hot fuser unit.

- Use caution when handling sharp objects, such as paper clips.

- Be aware of the moving parts of the machine.

- Follow the manufacturer’s instructions for safe operation.

5. What are the different types of paper that can be used in photocopying machines?

- Plain paper: The most common type of paper used for photocopying.

- Bond paper: A higher-quality paper than plain paper, with a smoother surface and a higher brightness.

- Card stock: A thick, durable paper that is used for business cards, postcards, and other special applications.

- Transparency film: A clear film that is used for creating overhead transparencies.

- Labels: A self-adhesive paper that is used for creating labels and stickers.

6. What are the different types of finishes that can be applied to copies?

- Glossy finish: A shiny finish that gives copies a professional look.

- Matte finish: A dull finish that is less reflective and easier to read.

- Satin finish: A semi-gloss finish that is a compromise between glossy and matte.

- Lamination: A clear plastic film that is applied to copies to protect them from wear and tear.

- Folding: Copies can be folded in half or in thirds to create booklets or brochures.

7. What are the different types of binding that can be applied to copies?

- Saddle stitching: A type of binding that uses staples to hold the pages together.

- Perfect binding: A type of binding that uses glue to hold the pages together.

- Spiral binding: A type of binding that uses a spiral-shaped wire to hold the pages together.

- Comb binding: A type of binding that uses a plastic comb to hold the pages together.

- Ring binding: A type of binding that uses metal rings to hold the pages together.

8. What are the different types of paper jams that can occur in photocopying machines?

- Misfeeds: Paper that is not fed into the machine correctly.

- Wrinkles: Paper that is wrinkled or folded, causing it to jam in the machine.

- Double feeds: Two sheets of paper that are fed into the machine at the same time.

- Paper jams: Paper that is stuck in the machine, preventing it from operating.

- Exit jams: Paper that is stuck in the exit tray of the machine.

9. How do you troubleshoot a paper jam in a photocopying machine?

- Open the machine and locate the jammed paper.

- Gently pull the paper out of the machine.

- Close the machine and restart it.

10. How do you maintain a photocopying machine to prevent paper jams?

- Keep the paper tray full.

- Avoid using wrinkled or folded paper.

- Clean the paper path regularly.

- Lubricate the moving parts of the machine.

- Follow the manufacturer’s instructions for maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photocopying Equipment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photocopying Equipment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photocopying Equipment Mechanics are responsible for the installation, maintenance, and repair of photocopying equipment. They work in a variety of settings, including offices, schools, and print shops. Their duties typically include:

1. Troubleshooting and repairing photocopying equipment

When a photocopying machine breaks down, it is the Photocopying Equipment Mechanic’s job to diagnose the problem and make repairs. This may involve replacing parts, adjusting settings, or cleaning the machine.

2. Installing and setting up photocopying equipment

When new photocopying equipment is purchased, it is the Photocopying Equipment Mechanic’s job to install and set it up. This may involve unpacking the machine, connecting it to power and data sources, and configuring it for use.

3. Providing preventive maintenance on photocopying equipment

To keep photocopying equipment running smoothly, it is important to perform preventive maintenance on a regular basis. This may involve cleaning the machine, inspecting parts for wear and tear, and replacing filters.

4. Training users on how to operate photocopying equipment

Once a photocopying machine is installed and set up, it is important to train users on how to operate it. This may involve teaching users how to make copies, scan documents, and send faxes.

Interview Tips

Preparing for an interview for a Photocopying Equipment Mechanic position can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go on an interview, it is important to do your research on the company and the position. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Photocopying Equipment Mechanic. Be prepared to talk about your experience in detail, and be sure to highlight your strengths and accomplishments. You can also bring a portfolio of your work to show the interviewer.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Photocopying Equipment Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!