Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Photoengraving Etcher Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

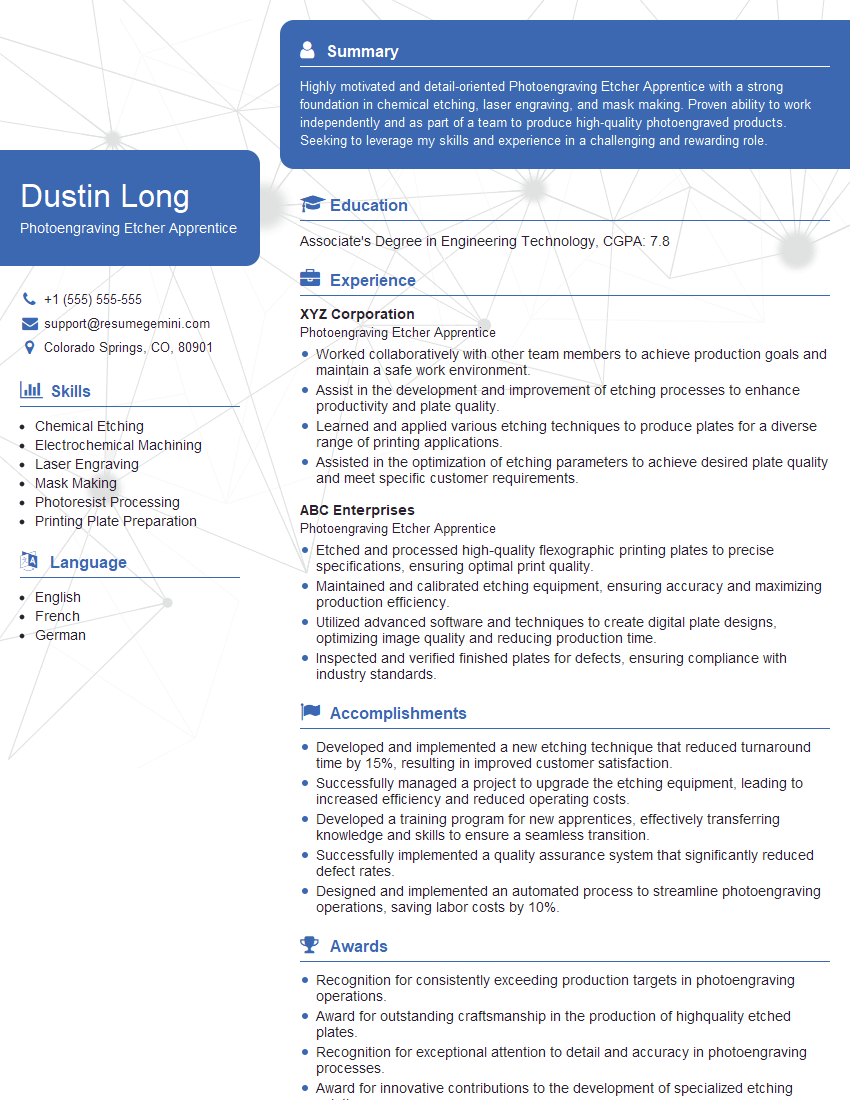

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photoengraving Etcher Apprentice

1. What are the different types of photoengraving etching processes, and what are the advantages and disadvantages of each?

- Line etching: This process creates a sharp, clean image. It is ideal for images that require precise detail, such as maps or technical drawings. However, it can be time-consuming and expensive.

- Halftone etching: This process creates a smooth, graduated image. It is ideal for images that require a wide range of tones, such as photographs or paintings. However, it can be difficult to control the quality of the image.

- Color etching: This process creates an image in color. It is ideal for images that require a high degree of realism. However, it is complex and expensive.

2. What are the different types of photoengraving plates?

Copper

- Advantages: Copper is durable and easy to engrave. It produces high-quality images with a long lifespan.

- Disadvantages: Copper is expensive and can be difficult to work with.

Zinc

- Advantages: Zinc is less expensive than copper and easier to engrave. It produces images with a good lifespan.

- Disadvantages: Zinc is not as durable as copper and can be more difficult to control the quality of the image.

Steel

- Advantages: Steel is very durable and produces high-quality images. It is also less expensive than copper.

- Disadvantages: Steel is difficult to engrave and can be more difficult to control the quality of the image.

3. What are the safety precautions that must be followed when working with photoengraving equipment?

- Wear protective clothing, including gloves, safety glasses, and a lab coat.

- Use proper ventilation to avoid inhaling fumes.

- Handle chemicals with care and dispose of them properly.

- Be aware of the potential for electrical hazards.

- Follow all manufacturer’s instructions.

4. What are the quality control procedures that must be followed during the photoengraving process?

- Check the quality of the original image.

- Inspect the photoengraving plate before and after etching.

- Proof the image to ensure that it meets the customer’s specifications.

- Keep records of all quality control procedures.

5. What are the troubleshooting techniques that can be used to resolve common problems that occur during the photoengraving process?

- Image is too light: Increase the exposure time or reduce the developer concentration.

- Image is too dark: Decrease the exposure time or increase the developer concentration.

- Image is blurry: Use a sharper lens or reduce the camera shake.

- Image is scratched: Clean the plate or use a different etching solution.

- Image is uneven: Use a more consistent etching solution or agitate the plate during etching.

6. What are the latest trends in photoengraving technology?

- Laser engraving: This process uses a laser to etch the plate. It is faster and more precise than traditional photoengraving methods.

- Digital photoengraving: This process uses a digital image to create the plate. It is more versatile and allows for more complex images than traditional photoengraving methods.

7. What are the different applications of photoengraving?

- Printing: Photoengraving is used to create printing plates for offset lithography, flexography, and gravure printing.

- Packaging: Photoengraving is used to create dies for stamping and embossing packaging materials.

- Jewelry: Photoengraving is used to create designs on jewelry.

- Decorative arts: Photoengraving is used to create decorative pieces, such as plates and sculptures.

8. What are the career opportunities for photoengraving apprentices?

- Photoengraver: Photoengravers use photoengraving equipment to create printing plates or other products.

- Etcher: Etchers use chemicals to etch designs into metal plates.

- Quality control inspector: Quality control inspectors ensure that photoengraving products meet specifications.

- Sales representative: Sales representatives sell photoengraving products and services.

9. What are the professional organizations for photoengravers?

- The International Photoengravers Union of North America (IPU): The IPU is a trade union that represents photoengravers in the United States and Canada.

- The Photoengravers Association of America (PAA): The PAA is a professional organization that represents photoengravers in the United States.

10. What are the educational requirements for photoengravers?

- Most photoengravers have a high school diploma or equivalent.

- Some photoengravers have a college degree in graphic arts or a related field.

- Photoengravers can also learn the trade through an apprenticeship program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photoengraving Etcher Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photoengraving Etcher Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photoengraving Etcher Apprentices provide support to Photoengraving Etchers in creating and developing photoengraved plates for use in the printing industry. Key job responsibilities include:

1. Assisting Etchers

Apprentices assist etchers by:

- Cutting and preparing metal plates

- Mixing chemicals to create etching solutions

- Cleaning and maintaining equipment

2. Learning Techniques

Apprentices learn etching techniques from etchers and other experienced professionals. They observe and study the etching process and practice their skills under supervision.

3. Etching Plates

As apprentices gain experience, they begin etching plates under the supervision of etchers. They use a variety of tools and techniques to create designs and images on metal plates.

4. Quality Control

Apprentices inspect etched plates for quality and accuracy. They ensure that the plates meet customer specifications and are free of defects.

5. Maintaining Records

Apprentices maintain records of etching processes, including the materials used, the etching time, and the results.

Interview Tips

To ace your interview for a Photoengraving Etcher Apprentice position, consider the following tips:

1. Research the Company and Position

Learn about the company’s history, products, and services. Research the specific role of the Photoengraving Etcher Apprentice and how it fits within the company’s operations.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience, such as your ability to mix chemicals, clean and maintain equipment, and etch metal plates. Highlight any previous experience in the printing or manufacturing industries.

3. Demonstrate Enthusiasm and Eagerness to Learn

Convey your passion for the craft of photoengraving and your eagerness to learn from experienced professionals. Show the interviewer that you are committed to developing your skills and becoming a proficient etcher.

4. Prepare Questions to Ask

Asking thoughtful questions demonstrates your interest in the position and the company. Prepare questions about the apprenticeship program, the company’s future plans, and the opportunities for career advancement.

5. Practice Your Answers

Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Rehearsing your answers will help you feel confident and articulate during the interview.

6. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving on time for your interview. Punctuality and a polished appearance show that you respect the interviewer and the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Photoengraving Etcher Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.