Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Photoengraving Machine Operator/Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Photoengraving Machine Operator/Tender so you can tailor your answers to impress potential employers.

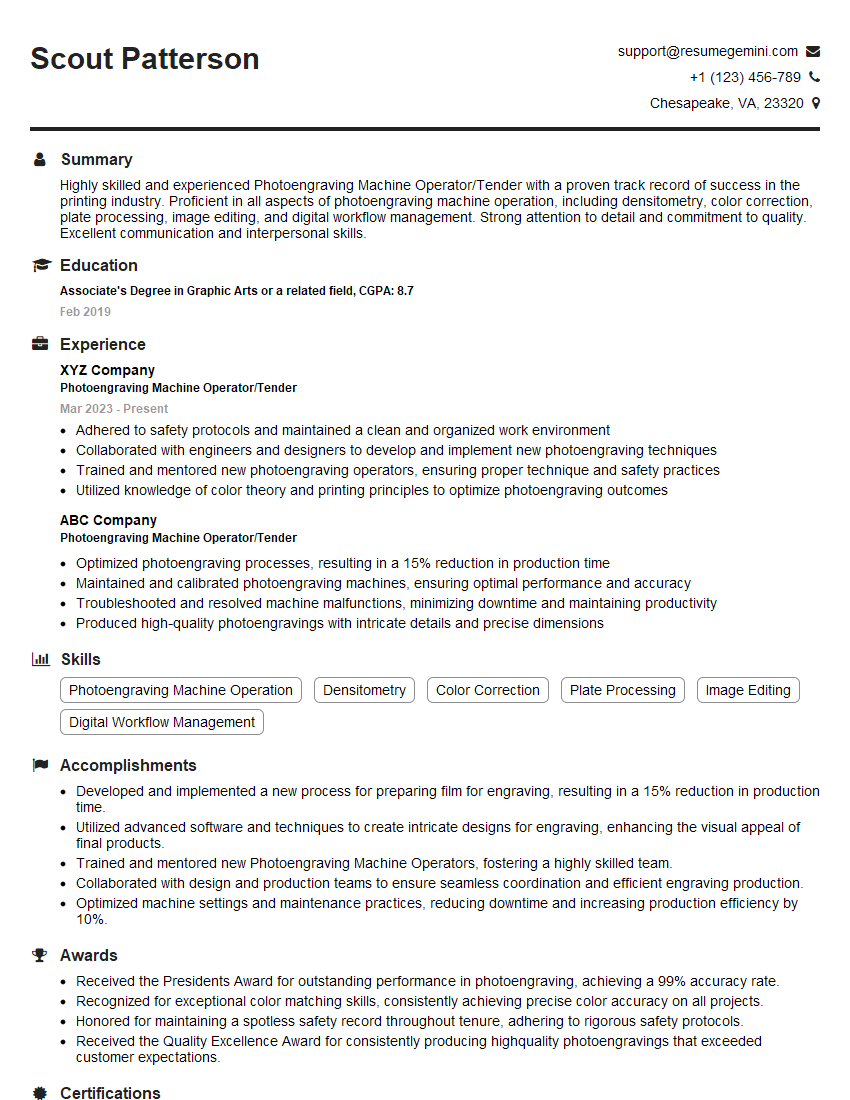

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photoengraving Machine Operator/Tender

1. What are the key responsibilities of a Photoengraving Machine Operator/Tender?

Key responsibilities of a Photoengraving Machine Operator/Tender include:

- Setting up and operating photoengraving machines to produce printing plates

- Preparing and processing photographic negatives and positives for use in the engraving process

- Monitoring the engraving process and making adjustments as needed

- Inspecting finished printing plates and ensuring they meet quality standards

- Maintaining and cleaning photoengraving equipment

2. What are the different types of photoengraving machines?

Computer-controlled photoengraving machines

- Use computer software to create precise engravings

- Offer a high level of automation and accuracy

Manual photoengraving machines

- Requre manual operation of the machine

- Offer greater flexibility and customization options

3. What are the different types of printing plates used in photoengraving?

Common types of printing plates used in photoengraving include:

- Copper plates: Durable and suitable for long print runs

- Zinc plates: Less durable than copper but more affordable

- Polymer plates: Lightweight and flexible, suitable for short print runs and variable data printing

4. Describe the process of preparing photographic negatives and positives for photoengraving.

Preparing photographic negatives and positives for photoengraving involves:

- Creating a digital or physical artwork

- Converting the artwork into a photographic negative or positive

- Developing and fixing the photographic image

5. What are the factors that affect the quality of photoengraved printing plates?

Factors affecting the quality of photoengraved printing plates include:

- Quality of the photographic negative or positive

- Precision of the photoengraving machine

- Etching depth and duration

- Plate material and thickness

6. How do you calibrate and maintain a photoengraving machine?

Calibrating and maintaining a photoengraving machine involves:

- Checking and adjusting the machine’s alignment and settings

- Cleaning and lubricating the machine’s components

- Performing regular maintenance checks and troubleshooting

7. What safety precautions should be taken when operating a photoengraving machine?

Safety precautions when operating a photoengraving machine include:

- Wearing appropriate safety gear, including gloves and eye protection

- Ensuring the machine is properly grounded

- Handling chemicals safely and disposing of them properly

- Following proper operating procedures and lockout/tagout protocols

8. How do you troubleshoot common problems with photoengraving machines?

Common problems with photoengraving machines and troubleshooting steps include:

- Uneven etching: Check and adjust the machine’s settings, including etching depth and exposure time

- Poor alignment: Calibrate the machine and ensure the artwork is properly positioned

- Blurred images: Clean the machine’s optics and check the quality of the photographic negative or positive

9. What are the latest advancements in photoengraving technology?

Recent advancements in photoengraving technology include:

- Increased automation and precision through computer-controlled machines

- Development of new plate materials with improved durability and print quality

- Integration with digital printing technologies for variable data printing and personalization

10. What are the career advancement opportunities for Photoengraving Machine Operators/Tenders?

Career advancement opportunities for Photoengraving Machine Operators/Tenders may include:

- Supervisor or lead operator

- Quality control technician

- Prepress or production manager

- Sales representative for photoengraving equipment or services

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photoengraving Machine Operator/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photoengraving Machine Operator/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photoengraving Machine Operators/Tenders are responsible for operating and maintaining photoengraving machines. They use these machines to create printing plates, which are used to print images and text onto paper and other materials. Photoengraving Machine Operators/Tenders must have a good understanding of the photoengraving process and be able to operate and maintain the machines safely and efficiently.

1. Set up and operate photoengraving machines

This includes loading the machine with the appropriate materials, setting the correct parameters for the engraving process, and starting the machine.

- Inspect raw materials, such as metal plates and films, to ensure they meet specifications.

- Load and unload materials into the photoengraving machine.

- Set up and adjust the machine according to job specifications.

- Monitor the engraving process and make adjustments as needed.

2. Maintain and troubleshoot photoengraving machines

This includes cleaning the machines, inspecting them for wear and tear, and making repairs as needed.

- Clean and maintain the machine according to manufacturer’s instructions.

- Inspect the machine regularly for signs of wear and tear.

- Troubleshoot and repair any problems that arise.

- Keep records of maintenance and repairs.

3. Inspect and quality control of finished products

This includes checking the printing plates for defects and ensuring that they meet the customer’s specifications.

- Inspect finished printing plates for defects.

- Measure and verify the dimensions of the printing plates.

- Ensure that the printing plates meet the customer’s specifications.

- Reject or approve printing plates for use.

4. Follow safety procedures

Photoengraving machines can be dangerous, so it is important for Photoengraving Machine Operators/Tenders to follow all safety procedures.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Follow all lockout/tagout procedures.

- Never operate a machine that is not in good working order.

- Report any accidents or injuries to your supervisor immediately.

Interview Tips

Preparing for an interview can be stressful, but it is important to remember that the interviewer wants to get to know you and your skills. By following these tips, you can increase your chances of success.

1. Research the company and the position

This will show the interviewer that you are interested in the company and the position. It will also help you to answer questions about the company and the position in a more informed way.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

- Review the job description carefully.

2. Practice your answers to common interview questions

This will help you to feel more confident and prepared during the interview. There are many common interview questions that you can practice, such as:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What are your salary expectations?”

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Photoengraving Machine Operator/Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!