Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician) so you can tailor your answers to impress potential employers.

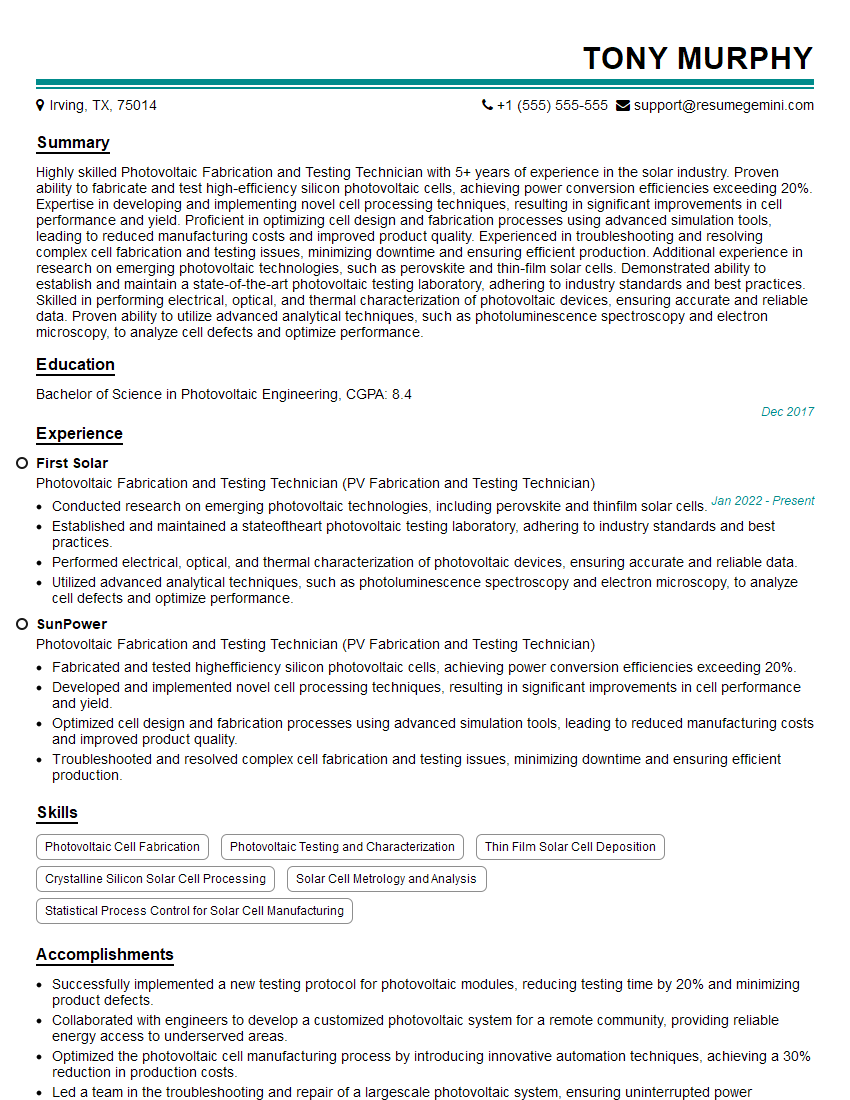

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician)

1. What are the key steps involved in the fabrication of a photovoltaic cell?

The key steps involved in the fabrication of a photovoltaic cell are:

- Substrate preparation: Cleaning and texturing the substrate to enhance light absorption.

- Deposition of semiconductor layers: Depositing thin layers of semiconductor materials, such as silicon or gallium arsenide, using techniques like chemical vapor deposition or molecular beam epitaxy.

- Junction formation: Creating a p-n junction within the semiconductor layers to separate charge carriers.

- Metallization: Depositing metal contacts on the cell’s surface to collect and transport current.

- Anti-reflection coating: Applying a coating to minimize light reflection and enhance cell efficiency.

- Encapsulation: Protecting the cell from environmental factors using materials like glass or polymers.

2. What techniques are used for testing the performance of photovoltaic cells?

IV curve measurement:

- Measuring the current-voltage (IV) curve of the cell to determine its electrical characteristics, such as open-circuit voltage, short-circuit current, and maximum power point.

Quantum efficiency measurement:

- Determining the percentage of incident photons converted into electrical current at different wavelengths.

Electroluminescence imaging:

- Examining the cell’s emission pattern under electrical bias to detect defects or variations in cell performance.

Thermal imaging:

- Measuring the temperature distribution of the cell under illumination to identify hot spots or areas of poor efficiency.

3. What are the common defects that can occur in photovoltaic cells during fabrication, and how can they be detected?

Common defects in photovoltaic cells include:

- Shunts: Short-circuits between the cell’s electrodes, reducing efficiency.

- Cracks: Breaks in the semiconductor material, causing performance degradation.

- Delamination: Separation between layers of the cell, affecting cell stability.

- Inclusions: Foreign particles or defects within the cell, impairing cell performance.

- Edge defects: Irregularities at the cell’s edges, leading to reduced efficiency.

Defects can be detected using various techniques, such as:

- Electroluminescence imaging

- Infrared imaging

- X-ray inspection

- Microscopic examination

4. How do you ensure the quality and reliability of photovoltaic cells during production?

To ensure quality and reliability:

- Use high-quality materials and adhere to strict manufacturing processes.

- Implement rigorous testing procedures throughout the production line to identify and eliminate defective cells.

- Conduct accelerated life testing to assess the long-term durability and performance of the cells.

- Establish a quality control system to monitor and maintain production standards.

- Continuously improve processes based on data analysis and feedback.

5. What are the latest advancements in photovoltaic cell technology, and how do they impact the industry?

Recent advancements include:

- Perovskite-based solar cells with high efficiency and low cost.

- Tandem solar cells combining different materials to enhance light absorption.

- Bifacial solar cells generating power from both sides.

- Flexible and lightweight solar cells for various applications.

These advancements are driving down costs, improving efficiency, and expanding the applications of photovoltaic technology.

6. How do you stay updated with the latest developments in the field of photovoltaic fabrication and testing?

- Attend industry conferences and workshops

- Read technical journals and publications

- Engage in online forums and discussion groups

- Participate in research and development projects

- Collaborate with experts and professionals

7. What is the role of automation in photovoltaic cell fabrication, and how does it benefit the manufacturing process?

- Increased efficiency and productivity

- Improved product quality and consistency

- Reduced labor costs and human error

- Enhanced safety and reduced risk of accidents

- Real-time monitoring and data collection for process optimization

8. How do you handle and address potential health and safety risks associated with photovoltaic cell fabrication and testing?

- Follow established safety protocols and wear appropriate personal protective equipment.

- Handle hazardous materials with care, ensuring proper ventilation and waste disposal.

- Understand the potential hazards of electrical equipment and take precautions to prevent accidents.

- Be aware of the risks associated with working with lasers and ultra-violet light.

- Participate in safety training programs and stay informed about industry best practices.

9. Can you describe a challenging project you worked on in the field of photovoltaic fabrication or testing, and how you overcame the challenges?

- Project description: Briefly describe the project, its objectives, and your role.

- Challenges encountered: Explain the specific technical or operational challenges you faced.

- Solutions implemented: Describe the innovative approaches or techniques you employed to overcome these challenges.

- Results achieved: Quantify the outcomes of your efforts, highlighting improvements in efficiency, quality, or productivity.

10. What are your career goals and aspirations in the field of photovoltaic technology?

- Express your enthusiasm for the industry and your desire to contribute to its advancement.

- Outline your specific interests within photovoltaic fabrication or testing, such as research and development, process optimization, or quality control.

- Explain how this role aligns with your career goals and how you envision your future growth within the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Photovoltaic Fabrication and Testing Technicians are responsible for the fabrication and testing of photovoltaic (PV) devices, which convert light energy into electrical energy. They work in cleanroom environments to perform tasks such as:

- Cleaning wafers to remove contaminants.

- Etching wafers to create patterns for cell structures.

- Depositing thin films of materials such as silicon, germanium, and gallium arsenide to form the active layers of PV cells.

- Soldering or welding cells together to form panels.

- Encapsulating panels in protective materials such as glass or plastic.

- Measuring the electrical properties of devices, such as current, voltage, and power output.

- Performing environmental testing to ensure devices can withstand harsh conditions.

- Identifying and repairing defects in PV cells or panels.

- Replacing faulty components.

1. Preparing semiconductor wafers

Preparing semiconductor wafers for PV cell fabrication by cleaning, etching, and depositing thin films.

2. Assembling PV cells

Assembling PV cells by connecting them together with conductive materials.

3. Testing PV devices

Testing PV devices to ensure they meet performance and quality standards.

4. Troubleshooting and repairing PV devices

Troubleshooting and repairing PV devices that fail to meet performance or quality standards.

Interview Tips

Here are some interview tips to help you ace your interview for a Photovoltaic Fabrication and Testing Technician position:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific skills and experience required for the role.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as they relate to the requirements of the position. Be prepared to discuss your experience in detail, and be sure to highlight any skills that are particularly relevant to the role.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are interested and engaged.

5. Follow up after the interview

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration, and to reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Photovoltaic Fabrication and Testing Technician (PV Fabrication and Testing Technician) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.