Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Photovoltaic Fabrication Technician (PV Fabrication Technician) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Photovoltaic Fabrication Technician (PV Fabrication Technician) so you can tailor your answers to impress potential employers.

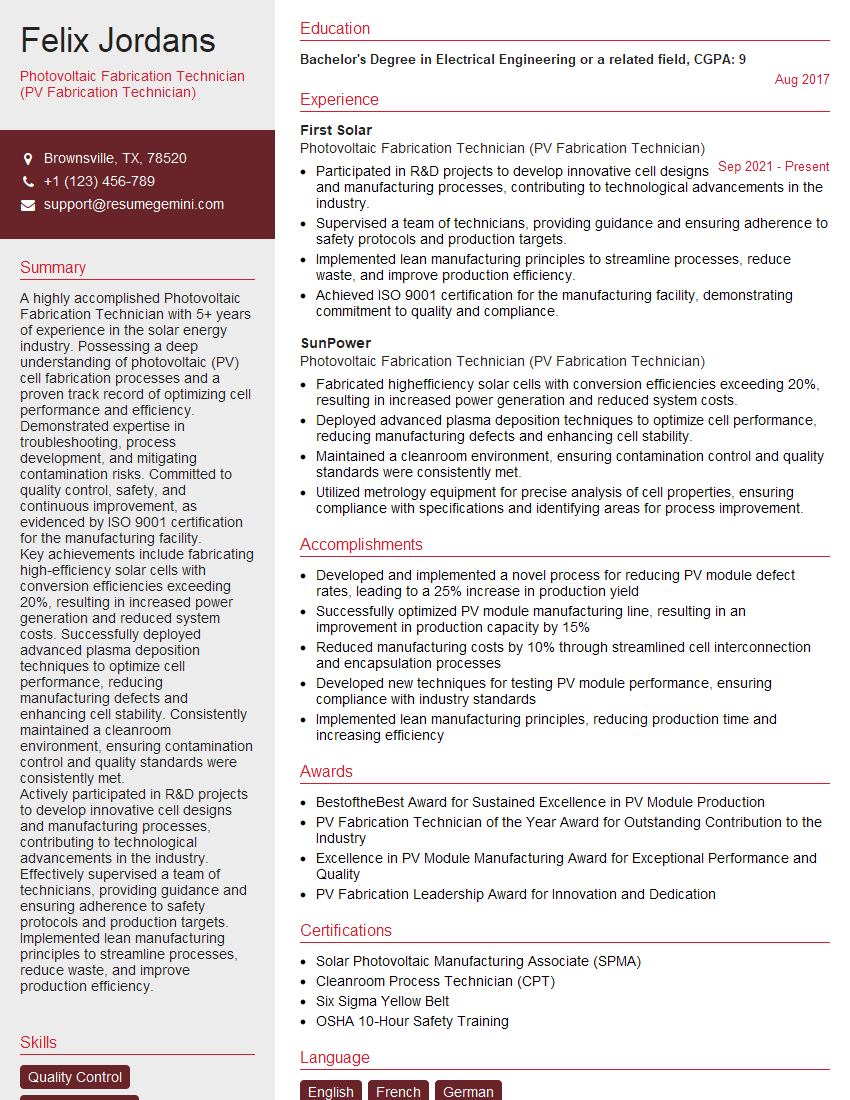

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Photovoltaic Fabrication Technician (PV Fabrication Technician)

1. What is the role of a Photovoltaic Fabrication Technician?

The primary responsibility of a Photovoltaic Fabrication Technician is to manufacture and assemble photovoltaic (PV) cells and modules. This involves performing various tasks throughout the production process, including:

- Preparing and cleaning substrates

- Depositing thin films

- Patterning and etching

- Interconnecting cells

- Encapsulating and laminating modules

- Testing and inspecting finished products

2. What are the different types of PV cells?

Monocrystalline cells

- Made from a single crystal of silicon

- Highest efficiency and longest lifespan

- Most expensive

Polycrystalline cells

- Made from multiple crystals of silicon

- Lower efficiency and shorter lifespan than monocrystalline cells

- Less expensive than monocrystalline cells

Thin-film cells

- Made from a thin layer of semiconductor material deposited on a substrate

- Lowest efficiency and shortest lifespan

- Least expensive

3. What are the key parameters that determine the performance of a PV module?

The key parameters that determine the performance of a PV module include:

- Efficiency: The percentage of sunlight that is converted into electricity

- Power output: The amount of electricity that the module can produce

- Voltage: The electrical potential difference between the positive and negative terminals

- Current: The flow of electrical charge

4. What are the different methods used to test PV modules?

The different methods used to test PV modules include:

- I-V curve tracing: Measures the current and voltage output of the module under different load conditions

- Electroluminescence imaging: Detects defects in the module by visualizing the emitted light

- Thermal imaging: Detects hot spots in the module that may indicate potential problems

- Environmental testing: Tests the module’s performance under different environmental conditions, such as temperature, humidity, and UV radiation

5. What are the safety precautions that must be taken when working with PV modules?

The safety precautions that must be taken when working with PV modules include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat

- Handling modules with care to avoid damage

- Not touching the electrical terminals of the module

- Working in a well-ventilated area

- Following all manufacturer’s instructions

6. What are the future trends in the PV industry?

The future trends in the PV industry include:

- Increased use of thin-film cells

- Development of more efficient cell designs

- Integration of PV modules into building materials

- Growth of the distributed generation market

- Decreasing costs of PV systems

7. What is your experience with using automated equipment in the fabrication of PV modules?

In my previous role at [company name], I was responsible for operating and maintaining a variety of automated equipment used in the fabrication of PV modules. This included:

- Screen printers

- Laminators

- Testers

I am proficient in troubleshooting and repairing these machines, and I have a strong understanding of their operating principles.

8. What is your experience with quality control in the PV industry?

In my previous role at [company name], I was responsible for implementing and maintaining a quality control program for the fabrication of PV modules. This included:

- Developing and implementing quality control procedures

- Inspecting raw materials and finished products

- Conducting audits of suppliers and subcontractors

I have a strong understanding of the quality standards for PV modules, and I am committed to ensuring that all products meet these standards.

9. What is your experience with working in a cleanroom environment?

In my previous role at [company name], I worked in a cleanroom environment for [number] years. I am familiar with the protocols and procedures for working in a cleanroom, and I have a strong understanding of the importance of maintaining a clean and contamination-free environment.

10. What are your strengths and weaknesses as a Photovoltaic Fabrication Technician?

Strengths

- Strong technical skills

- Experience with automated equipment

- Experience with quality control

- Ability to work in a cleanroom environment

- Attention to detail

Weaknesses

- Limited experience with thin-film cells

- Need to improve my knowledge of the latest PV technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Photovoltaic Fabrication Technician (PV Fabrication Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Photovoltaic Fabrication Technician (PV Fabrication Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Photovoltaic Fabrication Technician (PV Fabrication Technician) aims to produce high-quality photovoltaic (PV) cells and modules that meet technical specifications and industry standards. Their primary duties revolve around fabricating, assembling, and testing PV cells and modules, ensuring that they deliver optimal performance and reliability.

1. Manufacturing Processes

Involves executing various manufacturing processes, such as cell patterning, deposition, etching, and metallization, to create functional PV cells and modules.

- Perform cell patterning using photolithography or laser scribing techniques.

- Deposit thin films of semiconductor materials, such as silicon and compound semiconductors, using techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

- Etch away unwanted materials to create precise structures and patterns within the PV cells.

- Deposit metal contacts and electrodes to facilitate electrical connections.

2. Assembly and Integration

Assembles and integrates individual PV cells into modules, ensuring proper electrical connections and mechanical stability.

- Connect PV cells electrically in series or parallel configurations to achieve desired voltage and current output.

- Encapsulate PV cells in protective materials, such as glass or polymers, to enhance durability and weather resistance.

- Perform module assembly, including framing, mounting, and wiring, to create complete PV modules.

3. Quality Control and Testing

Conducts rigorous quality control and testing procedures to ensure that PV cells and modules meet specifications and industry standards.

- Perform electrical tests, such as IV curve tracing and electroluminescence imaging, to evaluate cell and module performance.

- Conduct environmental tests, including thermal cycling, humidity exposure, and mechanical stress, to assess module durability.

- Analyze test results and identify areas for process improvement.

4. Maintenance and Troubleshooting

Maintains and troubleshoots fabrication equipment to ensure optimal performance and minimize downtime.

- Perform regular maintenance on equipment, such as cleaning, calibration, and lubrication.

- Troubleshoot and resolve equipment malfunctions, identifying and repairing any issues promptly.

- Collaborate with maintenance teams to ensure ongoing equipment reliability.

Interview Tips

A successful interview for a Photovoltaic Fabrication Technician position requires preparation and showcasing your skills and knowledge to the interviewer. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. Understand their mission, values, and the role’s responsibilities. This knowledge will help you tailor your answers and show that you are genuinely interested in the opportunity.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience in PV cell and module fabrication, assembly, and testing. Quantify your accomplishments and use specific examples to demonstrate your capabilities. Highlight your technical skills, such as proficiency in semiconductor processing, thin film deposition, and electrical testing.

3. Showcase Industry Knowledge

Demonstrate your in-depth knowledge of the photovoltaic industry, including manufacturing processes, cell and module technologies, and industry standards. Discuss your understanding of the latest advancements in PV technology and how they impact the field.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to PV fabrication techniques, equipment operation, and quality control procedures. Review basic semiconductor physics concepts, such as bandgap, doping, and carrier transport. Practice explaining complex technical concepts in a clear and concise manner.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions about the company’s PV technology, manufacturing processes, and industry outlook. This shows your engagement and interest in the position and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Photovoltaic Fabrication Technician (PV Fabrication Technician), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Photovoltaic Fabrication Technician (PV Fabrication Technician) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.