Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Physical Metallurgist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

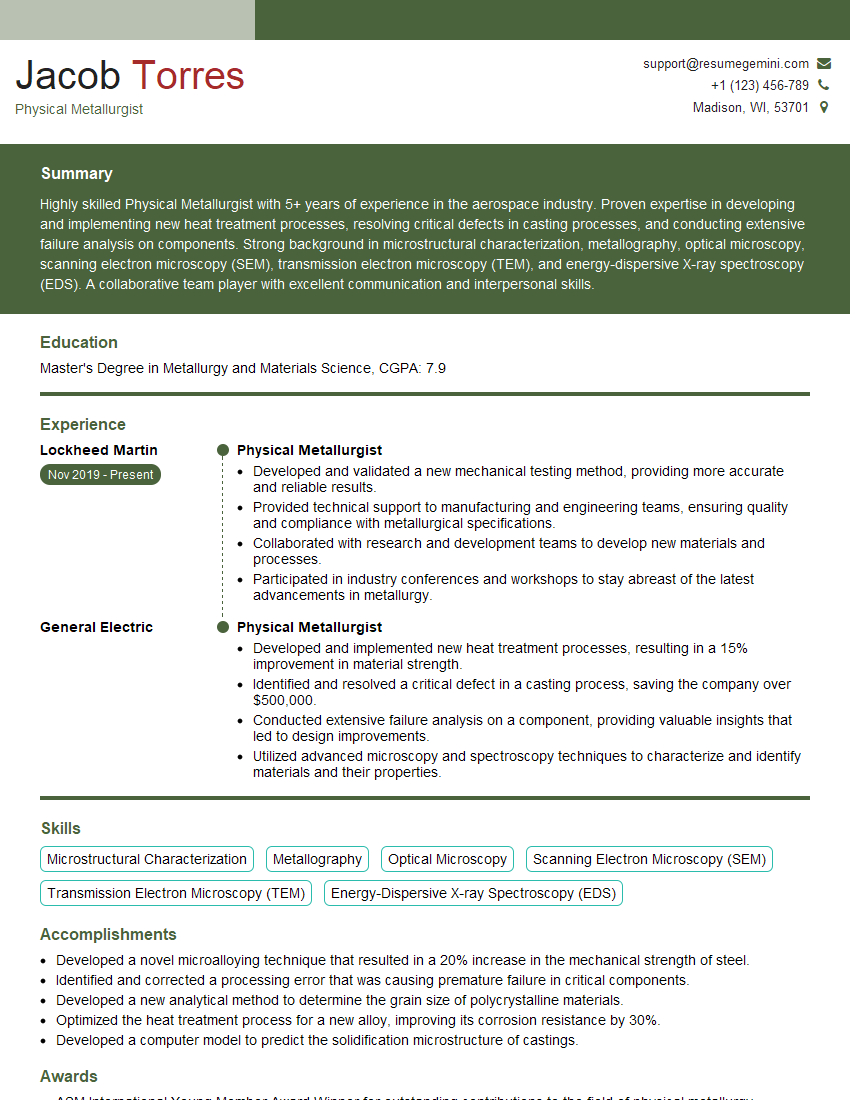

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Physical Metallurgist

1. What are the different types of crystal structures observed in metals?

There are three main types of crystal structures observed in metals: cubic, hexagonal, and tetragonal. Each type of structure has a different arrangement of atoms and a different set of properties.

- Cubic structures are the most common type of crystal structure in metals. They have a cubic unit cell with atoms arranged at each corner and in the center of each face. Cubic structures are found in metals such as aluminum, iron, and copper.

- Hexagonal structures have a hexagonal unit cell with atoms arranged at each corner and in the center of each face. Hexagonal structures are found in metals such as magnesium, zinc, and titanium.

- Tetragonal structures have a tetragonal unit cell with atoms arranged at each corner and in the center of each face. Tetragonal structures are found in metals such as tin and zirconium.

2. Explain the concept of phase diagrams.

Phase diagram shows the phases that are present in a system as a function of composition and temperature.

- Phase diagrams are used to predict the microstructure of a metal alloy.

- Phase diagrams can be used to determine the melting point, boiling point, and other physical properties of a metal alloy.

Phase diagrams are typically represented as a series of lines and curves on a graph.

- The lines represent the boundaries between different phases.

- The curves represent the temperatures at which different phases coexist.

3. What is the difference between a ferrous and a non-ferrous metal?

The main difference between ferrous and non-ferrous metals is that ferrous metals contain iron, while non-ferrous metals do not.

- Ferrous metals are typically stronger and harder than non-ferrous metals.

- Ferrous metals are also more magnetic than non-ferrous metals.

- Non-ferrous metals are typically more corrosion-resistant than ferrous metals.

- Non-ferrous metals are also more ductile and malleable than ferrous metals.

4. What are the different types of heat treatment processes used for metals?

Heat treatment processes are used to change the properties of a metal by heating and cooling it in a controlled manner.

- Annealing is a process that is used to soften a metal.

- Hardening is a process that is used to harden a metal.

- Tempering is a process that is used to toughen a metal.

- Normalizing is a process that is used to restore a metal to its original state after it has been cold worked.

5. What are the different types of corrosion?

Corrosion is the deterioration of a metal due to a chemical reaction with its environment.

- Uniform corrosion is a type of corrosion that occurs evenly over the entire surface of a metal.

- Galvanic corrosion is a type of corrosion that occurs when two dissimilar metals are in contact with each other.

- Pitting corrosion is a type of corrosion that occurs when small pits form on the surface of a metal.

- Crevice corrosion is a type of corrosion that occurs in the crevices between two pieces of metal.

6. What are the different types of mechanical testing used for metals?

Mechanical testing is used to determine the mechanical properties of a metal, such as its strength, hardness, and ductility.

- Tensile testing is a type of mechanical testing that is used to determine the strength and ductility of a metal.

- Compression testing is a type of mechanical testing that is used to determine the strength of a metal under compression.

- Hardness testing is a type of mechanical testing that is used to determine the hardness of a metal.

- Impact testing is a type of mechanical testing that is used to determine the toughness of a metal.

7. What is the difference between a composite material and a metal matrix composite?

Composite materials are made up of two or more different materials that are combined to create a new material with properties that are different from either of the individual materials.

- Metal matrix composites (MMCs) are a type of composite material in which the matrix is a metal and the reinforcement is a ceramic or a polymer.

- MMCs have a number of advantages over traditional metals, including improved strength, stiffness, and toughness.

8. What are the different types of welding processes used for metals?

Welding is a process that is used to join two or more pieces of metal together by melting the metal at the joint.

- Arc welding is a type of welding that uses an electric arc to melt the metal at the joint.

- Gas welding is a type of welding that uses a flame to melt the metal at the joint.

- Resistance welding is a type of welding that uses pressure and heat to weld the metal at the joint.

9. What are the different types of metal forming processes?

Metal forming processes are used to shape metal into different shapes and sizes.

- Forging is a metal forming process that uses pressure to shape metal.

- Rolling is a metal forming process that uses rollers to shape metal.

- Drawing is a metal forming process that uses a die to shape metal.

- Extrusion is a metal forming process that uses a ram to force metal through a die.

10. What are the different types of metal finishing processes?

Metal finishing processes are used to improve the appearance and properties of metal surfaces.

- Plating is a metal finishing process that uses a chemical solution to deposit a thin layer of metal on a surface.

- Anodizing is a metal finishing process that uses an electrochemical process to create a protective oxide layer on a surface.

- Painting is a metal finishing process that uses a liquid coating to create a protective and decorative finish on a surface.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Physical Metallurgist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Physical Metallurgist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Physical metallurgists are materials scientists who specialize in the study of the physical properties of metals. They use their knowledge to develop new alloys and improve the properties of existing ones.

1. Conduct research on the physical properties of metals.

Physical metallurgists study the physical properties of metals, such as their strength, hardness, and ductility. They use this information to develop new alloys and improve the properties of existing ones.

- Design and conduct experiments to study the physical properties of metals.

- Analyze data and write reports on their findings.

2. Develop new alloys.

Physical metallurgists develop new alloys by combining different elements in different proportions. They then test the properties of these alloys to see if they meet the desired specifications.

- Identify the properties that are needed for a particular application.

- Combine different elements in different proportions to create new alloys.

- Test the properties of these alloys to see if they meet the desired specifications.

3. Improve the properties of existing alloys.

Physical metallurgists also work to improve the properties of existing alloys. They may do this by adding different elements to the alloy, by changing the heat treatment process, or by using different forming techniques.

- Identify the properties that need to be improved in an existing alloy.

- Develop new methods to improve these properties.

- Test the properties of the improved alloy to see if it meets the desired specifications.

4. Work with other engineers and scientists to develop new products.

Physical metallurgists often work with other engineers and scientists to develop new products. They may be involved in the design of new products, the development of new manufacturing processes, or the testing of new products.

- Collaborate with other engineers and scientists to develop new products.

- Provide input on the design of new products.

- Develop new manufacturing processes.

- Test new products to ensure that they meet the desired specifications.

Interview Tips

Preparing for a physical metallurgist interview can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position.

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and identify the key qualifications and responsibilities.

2. Practice your answers to common interview questions.

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Dress professionally.

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure that your shoes are clean and polished.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing clothing that is too revealing or too casual.

- Make sure your shoes are clean and polished.

4. Be yourself.

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Don’t be afraid to show your personality.

- Be confident and enthusiastic.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Physical Metallurgist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Physical Metallurgist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.