Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Picker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

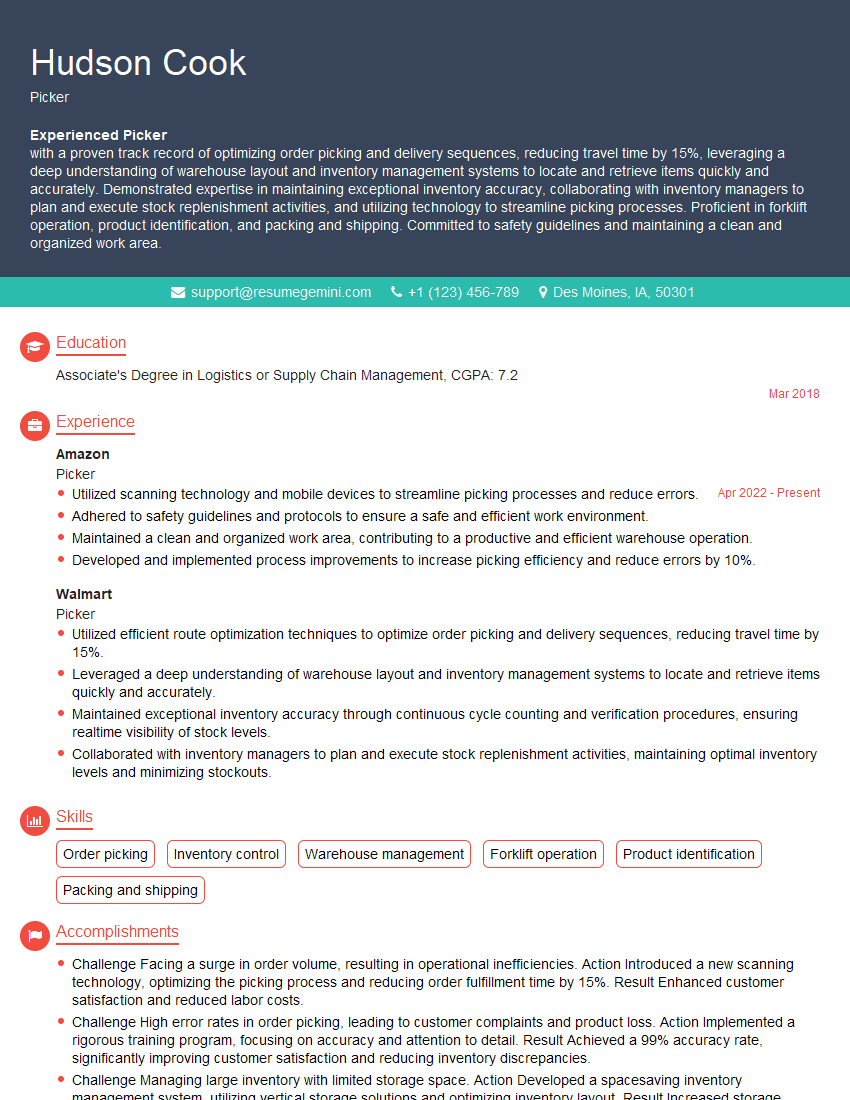

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Picker

1. What are the different types of picking methods used in warehouses?

There are several types of picking methods used in warehouses, each with its own advantages and disadvantages. Some of the most common picking methods include:

- Zone picking: This method involves dividing the warehouse into zones, and assigning each zone to a specific picker. Pickers then responsible for picking all orders within their assigned zone.

- Batch picking: This method involves picking multiple orders at the same time. Pickers use a picking list to identify the items that need to be picked for each order, and then pick all of the items for those orders in one batch.

- Wave picking: This method involves picking orders in waves. A wave is a group of orders that are picked at the same time. Pickers are assigned to pick orders within a specific wave, and then all of the orders in that wave are picked at the same time.

- Discrete picking: This method involves picking each order individually. Pickers are assigned to pick a specific order, and then they pick all of the items for that order before moving on to the next order.

2. What are the factors that need to be considered when choosing a picking method?

Factors to consider when choosing a picking method include:

- The size of the warehouse

- The number of orders that are processed each day

- The types of items that are being picked

- The accuracy requirements

- The labor costs

Other factors that may need to be considered could be:

- The availability of technology

- The training level of the pickers

- The customer service requirements

3. What are the advantages and disadvantages of using a pick to light system?

Pick to light systems are a type of order picking technology that uses lights to guide pickers to the correct location of the items that they need to pick. Pick to light systems can improve picking accuracy and speed, and can also reduce labor costs.

Advantages of using a pick to light system include:

- Improved picking accuracy

- Increased picking speed

- Reduced labor costs

- Simplified training process

Disadvantages of using a pick to light system include:

- High cost of implementation

- Can be inflexible

- Requires a dedicated picking area

4. What are the different types of automated picking systems?

Automated picking systems are used to automate the picking process. There are several different types of automated picking systems, each with its own advantages and disadvantages.

Some of the most common types of automated picking systems include:

- Goods-to-person: Goods-to-person systems are automated picking systems that bring the items to the picker. Pickers then pick the items from the conveyor belt or other automated system.

- Person-to-goods: Person-to-goods systems are automated picking systems that require the picker to travel to the location of the items. Pickers then pick the items from the shelves or other storage locations.

- Hybrid: Hybrid systems are automated picking systems to combine elements of both goods-to-person and person-to-goods systems.

5. What are the factors that need to be considered when choosing an automated picking system?

Factors that need to be considered when choosing an automated picking system include:

- The size of the warehouse

- The number of orders that are processed each day

- The types of items that are being picked

- The accuracy requirements

- The labor costs

- The capital costs

6. What are the benefits of using an automated picking system?

Benefits of using an automated picking system include:

- Improved picking accuracy

- Increased picking speed

- Reduced labor costs

- Simplified training process

- Improved customer service

7. What are the challenges of using an automated picking system?

Challenges of using an automated picking system include:

- High cost of implementation

- Can be inflexible

- Requires a dedicated picking area

- May require specialized training

8. What are the latest trends in automated picking systems?

The latest trends in automated picking systems include the increasing use of robotics, the use of artificial intelligence (AI) to optimize picking operations, and the development of new types of automated picking systems that are more flexible and affordable.

Some of the most notable trends in automated picking systems include:

- The increasing use of robotics: Robots are being used to automate a variety of tasks in the warehouse, including picking. Robots can be used to pick items from shelves, conveyor belts, and other storage locations.

- The use of artificial intelligence (AI) to optimize picking operations: AI is being used to optimize picking operations by analyzing data and identifying inefficiencies. AI can be used to create picking routes, assign pickers to orders, and manage inventory levels.

- The development of new types of automated picking systems that are more flexible and affordable: New types of automated picking systems are being developed that are more flexible and affordable than traditional systems. These systems are designed to meet the needs of smaller warehouses and businesses with limited budgets.

9. What are the future prospects for automated picking systems?

The future prospects for automated picking systems are positive. The increasing use of e-commerce is driving the demand for automated picking systems. As e-commerce continues to grow, the demand for automated picking systems is expected to increase.

In addition, the development of new technologies is making automated picking systems more affordable and flexible. This is making automated picking systems a more viable option for smaller warehouses and businesses with limited budgets.

10. What are the key factors to consider when implementing an automated picking system?

The key factors to consider when implementing an automated picking system include:

Considerations when implementing an automated picking system include:

- The size of the warehouse

- The number of orders that are processed each day

- The types of items that are being picked

- The accuracy requirements

- The labor costs

- The capital costs

- The availability of technology

- The training level of the pickers

- The customer service requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Picker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Picker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pickers are responsible for accurately and efficiently retrieving and moving goods within a warehouse or other storage facility.

1. Order Fulfillment

Pickers retrieve items from storage locations based on customer orders or other instructions.

- Identify and locate specific items using order picking lists or inventory management systems.

- Verify the accuracy and quantity of items picked against orders.

2. Stock Management

Pickers maintain inventory levels and ensure that items are properly stored and organized.

- Monitor inventory levels and replenish stock as needed.

- Organize and maintain storage areas to optimize space and accessibility.

3. Equipment Operation

Pickers operate various equipment such as forklifts, pallet jacks, and conveyors to efficiently move goods.

- Operate forklifts and pallet jacks to retrieve and transport items.

- Utilize conveyors to streamline the picking and movement of goods.

4. Quality Control

Pickers ensure that items are not damaged or defective when picked.

- Inspect items for any damage or defects before picking.

- Handle items with care to prevent any damage during transportation.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your Picker interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and values. Understand the specific responsibilities and requirements of the Picker position.

- Visit the company’s website and social media pages.

- Read industry news and articles related to the position and the company’s operations.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in order picking, inventory management, and equipment operation.

- Quantify your accomplishments and provide specific examples of your work.

- Use action verbs and specific terms to describe your responsibilities.

3. Demonstrate Your Attention to Detail and Accuracy

Pickers must have a strong attention to detail and accuracy. Highlight your ability to focus on tasks and minimize errors.

- Mention your experience with inventory control and order fulfillment systems.

- Emphasize your attention to detail and accuracy in previous roles.

4. Be Prepared to Discuss Safety Regulations

Safety is paramount in warehouse operations. Demonstrate your knowledge of safety regulations and your commitment to following proper procedures.

- Discuss your experience with safety protocols and regulations.

- Explain how you maintain a safe work environment and handle hazardous materials.

5. Ask Thoughtful Questions

Asking thoughtful questions shows your interest in the position and the company. Prepare a few questions related to the job responsibilities, company culture, or industry trends.

- Ask about the company’s growth plans or sustainability initiatives.

- Inquire about the training and development opportunities available.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Picker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!