Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Piece Dyer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Piece Dyer so you can tailor your answers to impress potential employers.

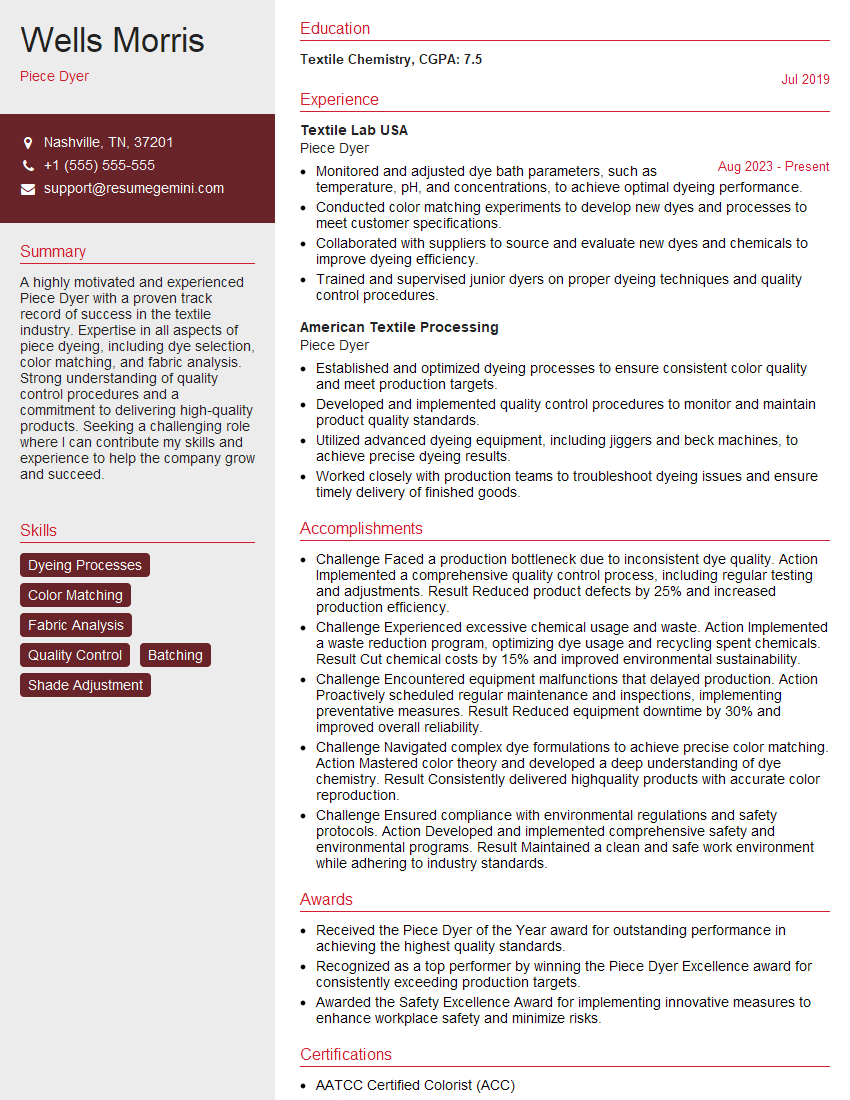

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Piece Dyer

1. Explain the process of dyeing different types of fibres, such as cotton, wool, and synthetic fibres?

- For cotton fibres, I start by scouring the fabric to remove any impurities that may interfere with dye absorption. I then apply a mordant, which helps the dye bond with the cotton fibres. After mordanting, I immerse the fabric in a dye bath and control the temperature, pH, and time to achieve the desired colour.

- With wool fibres, I begin by preparing the fabric with a scouring and bleaching process. I then apply acid dyes, which are specifically designed for wool and provide excellent colourfastness. The dyeing process involves careful control of temperature, pH, and time to achieve the desired shade.

- For synthetic fibres, such as polyester and nylon, I use disperse dyes or cationic dyes. These dyes have an affinity for synthetic fibres and require specific dyeing techniques. I adjust the pH of the dye bath and use appropriate dyeing auxiliaries to ensure even dye penetration and colour development.

2. How do you determine the correct dye concentration and application method for a given fabric and colour requirement?

Lab Dips

- I conduct lab dips to determine the optimal dye concentration and application method. Lab dips involve dyeing small fabric samples under various conditions to assess colour development and fastness properties.

- By analysing the lab dips, I can evaluate the dye’s affinity for the fabric, the levelness of the dyeing, and the colourfastness to factors like washing, light, and rubbing.

Experience and Knowledge

- I rely on my extensive experience and knowledge of different dyes and fabrics to make informed decisions about dye concentration and application methods.

- I consider factors such as the fibre type, fabric construction, desired shade, and end-use requirements to determine the most appropriate dyeing parameters.

3. Describe the quality control measures you implement to ensure the accuracy and consistency of the dyeing process?

- I maintain strict control over the dyeing process parameters, including temperature, pH, and time, to ensure consistent colour reproduction.

- I regularly calibrate and maintain the dyeing equipment to ensure accuracy and prevent variations in dye application.

- I conduct ongoing colour matching and spectrophotometer analysis to verify the colour accuracy against approved standards.

- I implement statistical process control techniques to monitor and analyse dyeing data, identify trends, and make necessary adjustments to maintain process stability.

4. How do you troubleshoot and resolve common dyeing problems, such as uneven dyeing, colour bleeding, and shade variation?

- To troubleshoot uneven dyeing, I check for proper fabric preparation, dye bath agitation, and temperature control. I adjust the dyeing parameters and ensure even dye penetration.

- For colour bleeding, I identify the source of the bleeding (e.g., unfixed dye, dye migration) and apply appropriate remedies such as after-treatment or colour-fixing agents.

- To resolve shade variation, I analyse the dyeing process, check for dye lot consistency, and adjust the dye concentration or application method to achieve the desired shade.

5. What are the environmental considerations and sustainability practices you follow in your dyeing operations?

- I use eco-friendly dyes and auxiliaries that meet environmental regulations and minimise the impact on the environment.

- I optimise the dyeing process to reduce water and energy consumption. I implement water recycling and heat recovery systems to conserve resources.

- I adhere to proper waste management practices, including the treatment and disposal of wastewater and dye sludge in accordance with environmental regulations.

6. How do you stay up-to-date with the latest advancements and best practices in the dyeing industry?

- I attend industry conferences and workshops to learn about new technologies and innovative dyeing techniques.

- I collaborate with dye manufacturers and research institutions to gain insights into the latest dye chemistry and application methods.

- I actively participate in industry associations and discussion forums to connect with other professionals and exchange knowledge.

7. What are the key factors you consider when selecting dyes and auxiliaries for a particular dyeing project?

- I assess the fibre type, fabric construction, and desired colour to select dyes with the appropriate affinity and colourfastness properties.

- I consider the end-use requirements, such as lightfastness, washfastness, and rubfastness, to ensure the dyed fabric meets the necessary performance standards.

- I evaluate the cost, availability, and environmental impact of different dyes and auxiliaries to make informed decisions.

8. How do you handle and store dyes and chemicals safely, ensuring the health and safety of yourself and others?

- I follow established safety protocols for handling and storing dyes and chemicals.

- I wear appropriate personal protective equipment (PPE), such as gloves, masks, and protective clothing, when working with hazardous materials.

- I store dyes and chemicals in designated, well-ventilated areas, away from incompatible substances.

- I dispose of waste dyes and chemicals in accordance with environmental regulations.

9. Describe a challenging dyeing project you encountered and how you successfully resolved the issue.

Project:

- I was tasked with dyeing a large batch of silk fabric in a delicate shade of lavender.

- The fabric was prone to uneven dyeing and colour bleeding, making it difficult to achieve the desired uniform shade.

Solution:

- I conducted extensive lab dips to determine the optimal dye concentration and application method.

- I adjusted the dyeing process parameters, including temperature, pH, and agitation, to minimise uneven dyeing.

- I added a colour-fixing agent to prevent colour bleeding and improve washfastness.

- I closely monitored the dyeing process and made necessary adjustments based on the ongoing colour analysis.

Results:

10. What are your strengths and weaknesses as a Piece Dyer?

Strengths:

- Extensive knowledge of dyeing processes for various fibres and fabrics.

- Proven ability to achieve accurate colour reproduction and consistent dyeing results.

- Strong troubleshooting skills to resolve dyeing problems effectively.

- Commitment to quality control and meeting industry standards.

Weaknesses:

- Limited experience with digital printing techniques.

- I am always eager to expand my knowledge and skills to overcome any perceived weaknesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Piece Dyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Piece Dyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Piece Dyers are responsible for colouring fabrics, yarns, or other materials, ensuring colour uniformity and adherence to specified quality standards. Their responsibilities include:

1. Dyeing Process Execution

Set up and operate dyeing machines, following specified dyeing recipes and procedures.

- Prepare dye solutions and measure chemical additions accurately.

- Control dyeing parameters like temperature, pH, and agitation.

2. Colour Matching and Quality Control

Match colours to customer specifications using colour measuring and matching devices.

- Conduct shade analysis and make adjustments to achieve colour consistency.

- Inspect dyed materials for defects and ensure adherence to quality standards.

3. Equipment Maintenance and Troubleshooting

Maintain and calibrate dyeing machines to ensure optimal performance.

- Identify and resolve technical issues that arise during the dyeing process.

- Follow safety protocols and ensure a clean and organized work area.

4. Process Optimization and Cost Control

Work with production teams to identify areas for process improvement.

- Monitor chemical usage and implement measures to reduce costs.

- Maintain records and documentation related to the dyeing process.

Interview Tips

To ace the interview for a Piece Dyer position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s dyeing capabilities, product offerings, and industry reputation.

- Review the job description thoroughly to understand the specific requirements.

- Prepare questions to ask the interviewer about the company’s dyeing processes and quality standards.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating dyeing machines and your understanding of colour matching techniques.

- Quantify your accomplishments by providing specific examples of successful dye batches or process improvements you have implemented.

- Demonstrate your attention to detail and commitment to quality control.

3. Showcase Problem-Solving Abilities

Explain how you have handled unexpected challenges during the dyeing process and resolved them effectively.

- Describe a time when you had to troubleshoot a malfunctioning dyeing machine or correct a colour deviation.

- Emphasize your ability to think critically and find solutions quickly.

4. Practice Common Interview Questions

Prepare for common interview questions related to dyeing and textile industry knowledge, such as:

- “Describe the different types of dyes and their applications.”

- “How do you monitor the dyeing process to ensure colour consistency?”

- “What are the most important quality control checks in dyeing?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Piece Dyer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.