Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Piece Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Piece Maker so you can tailor your answers to impress potential employers.

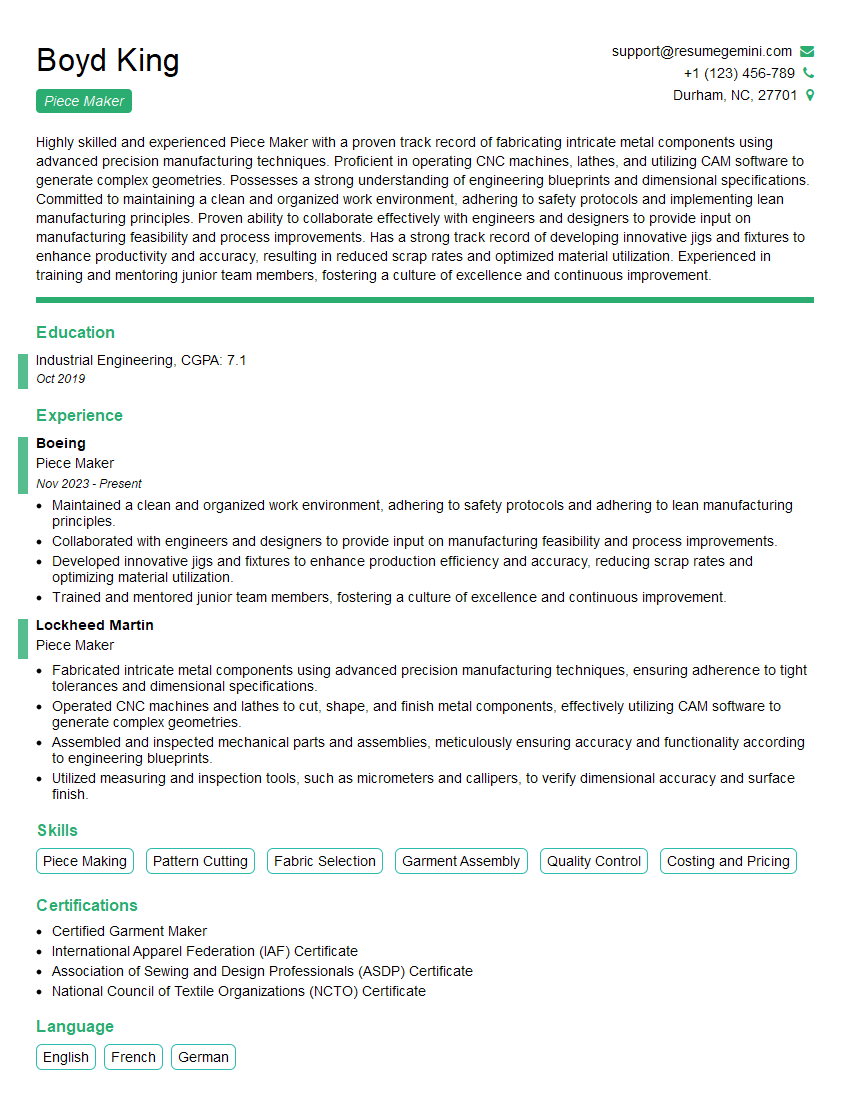

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Piece Maker

1. What are the different types of piecemaking techniques?

Piecemaking involves joining together smaller pieces of fabric to create a larger piece. There are several techniques used for piecemaking, including:

- English paper piecing: Involves using paper templates to create individual fabric pieces that are then sewn together.

- Foundation piecing: Involves sewing fabric strips to a foundation fabric to create a specific pattern or design.

- Machine piecing: Involves using a sewing machine to join fabric pieces together, typically using a straight stitch or zigzag stitch.

- Hand piecing: Involves sewing fabric pieces together by hand using a needle and thread, often using a whip stitch or blind stitch.

- Appliqué: Involves attaching fabric pieces to a base fabric using fusible adhesive or stitches.

2. What are the advantages of using a rotary cutter and mat for piecemaking?

Accuracy:

- Rotary cutters provide precise cuts, resulting in more accurate and consistent seam allowances.

Efficiency:

- Rotary cutters allow for faster cutting than traditional scissors, especially when making multiple cuts.

Safety:

- Rotary cutters are safer than scissors as they reduce the risk of accidental cuts.

Ergonomics:

- Rotary cutters require less hand movement, reducing strain and fatigue.

3. How do you ensure accurate seam allowances when piecing?

Ensuring accurate seam allowances is crucial for successful piecemaking. Some techniques to achieve this include:

- Using a consistent seam guide: Setting the seam guide on your sewing machine to the desired seam allowance and maintaining it throughout the piecing process.

- Measuring and marking the seam allowance: Using a ruler or measuring tape to mark the seam allowance on the fabric before sewing.

- Chainstitching: Sewing a line of stitches along the seam allowance to stabilize the fabric and prevent fraying.

- Pressing the seams: Pressing the seams open after sewing helps flatten the fabric and set the seam allowance accurately.

4. What are the different types of presser feet for piecemaking?

Presser feet are attachments used on sewing machines to assist in specific sewing tasks. For piecemaking, common presser feet include:

- Standard presser foot: Used for general sewing, including piecing.

- Quarter-inch presser foot: Specifically designed for sewing quarter-inch seams, providing an accurate seam allowance guide.

- Walking foot: Helpful for feeding multiple layers of fabric evenly, ensuring even stitching.

- Bias binder presser foot: Used for creating and attaching bias binding tape.

- Reverse-feed presser foot: Used for inserting zippers and sewing around curves.

5. How do you make a quilt sandwich?

A quilt sandwich consists of three layers: the quilt top, batting, and backing. To make a quilt sandwich:

- Layer the batting: Spread the batting evenly over the work surface.

- Place the quilt top: Center the quilt top over the batting, ensuring it is flat and smooth.

- Lay the backing: Place the backing fabric on top of the quilt top, right side down.

- Smooth and pin: Smooth the layers together and pin them securely around the edges.

- Quilt: The quilt sandwich is now ready for quilting.

6. What are the different methods of quilting?

Quilting involves stitching through all three layers of the quilt sandwich to secure them together and create a decorative effect. Common quilting methods include:

- Hand quilting: Using a needle and thread to stitch through the layers by hand.

- Machine quilting: Using a sewing machine to stitch through the layers.

- Longarm quilting: Using a specialized longarm quilting machine that provides a larger work surface and allows for more intricate quilting designs.

- Trapunto quilting: Creating raised padded designs by adding extra batting or stuffing between the layers.

- Appliqué quilting: Incorporating fabric appliqués into the quilt design and quilting around them.

7. What are the different types of quilting patterns?

Quilting patterns provide a guide for stitching the quilt sandwich. There are numerous quilting patterns to choose from, including:

- Grid quilting: Stitching in straight lines creating a grid pattern.

- Free-motion quilting: Stitching without using a pattern, allowing for more organic and creative designs.

- Echo quilting: Stitching parallel lines around a central motif or design.

- Meander quilting: Stitching a continuous line that meanders around the quilt.

- Stipple quilting: Stitching small, even stitches to create a textured effect.

8. How do you prepare a quilt for binding?

Before binding a quilt, it is important to prepare it properly:

- Trim the excess: Trim any excess batting or backing fabric around the edges of the quilt.

- Square the edges: Ensure that the edges of the quilt are square and even.

- Press the edges: Press the raw edges of the quilt top and backing inward by about 1/4 inch.

- Bind the quilt: Fold the binding strip over the pressed edges and stitch it securely.

9. What are the different types of quilt bindings?

Quilt bindings are used to finish the edges of a quilt and provide a decorative touch. Common types of quilt bindings include:

- Single-fold binding: A simple binding that is folded over the quilt edge once and stitched in place.

- Double-fold binding: A more durable binding that is folded over the quilt edge twice and stitched in place.

- Bias binding: A strip of fabric cut on the bias, which provides stretch and helps curves smoothly.

- Faced binding: A binding that has a facing fabric attached to the back, providing a more finished look.

- Machine-stitched binding: A binding that is sewn on using a sewing machine.

10. How do you care for a quilt?

Proper care is essential to maintaining the beauty and longevity of quilts:

- Gentle washing: Machine wash quilts on a gentle cycle using cold water and mild detergent.

- Air drying: Air dry quilts as much as possible to prevent shrinkage and damage.

- Ironing: Iron quilts on a low heat setting using a pressing cloth to protect the fabric.

- Storage: Store quilts in a cool, dry place away from direct sunlight.

- Professional cleaning: For heavily soiled quilts, consider professional cleaning.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Piece Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Piece Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Piece Makers are responsible for assembling parts and products, working with various tools and machinery.

1. Assembling Products

Assemble products according to blueprints, schematics, or oral instructions.

- Follow assembly procedures and quality standards.

- Identify and correct assembly defects.

2. Operating Machinery

Operate machinery such as presses, drills, saws, and welders.

- Set up and calibrate machinery.

- Monitor and maintain machinery.

3. Inspecting Products

Inspect products for defects and ensure they meet quality standards.

- Use gauges, micrometers, and other measuring tools.

- Identify and report any quality issues.

4. Maintaining Work Area

Maintain a clean and organized work area.

- Follow safety procedures.

- Keep tools and equipment in good condition.

Interview Tips

To ace an interview for a Piece Maker position, it’s crucial to prepare thoroughly and showcase your skills and experience. Here are some tips:

1. Research the Company and Position

Before the interview, research the company and the specific Piece Maker position you’re applying for. Understanding the company’s values, products or services, and industry will give you an advantage.

- Visit the company website and social media pages.

- Read industry publications and news articles.

- Study the job description and identify the key responsibilities and qualifications.

2. Prepare Your Skills and Experience

Highlight your skills and experience that are relevant to the Piece Maker position. Focus on your ability to assemble products, operate machinery, inspect products, and maintain a clean work area.

- Quantify your achievements and provide specific examples.

- Practice describing your skills and experience in a clear and concise manner.

- Prepare examples of projects or tasks you’ve completed that demonstrate your abilities.

3. Practice Common Interview Questions

Prepare for common interview questions, including those related to your skills, experience, and motivation. Research typical interview questions and practice your answers.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Can you provide an example of a time you solved a problem in the workplace?

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you’re serious about the position.

- Choose appropriate business attire, such as a suit or dress.

- Be punctual and plan your travel route in advance to avoid delays.

- If possible, visit the interview location beforehand to familiarize yourself with the surroundings.

5. Be Enthusiastic and Ask Questions

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you’re genuinely interested in the position and the company.

- Don’t be afraid to ask questions about the role, the company, and the industry.

- This demonstrates your engagement and interest in learning more about the opportunity.

- Prepare a few questions to ask the interviewer, such as about the company’s culture or future plans.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Piece Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.