Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pigment Furnace Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

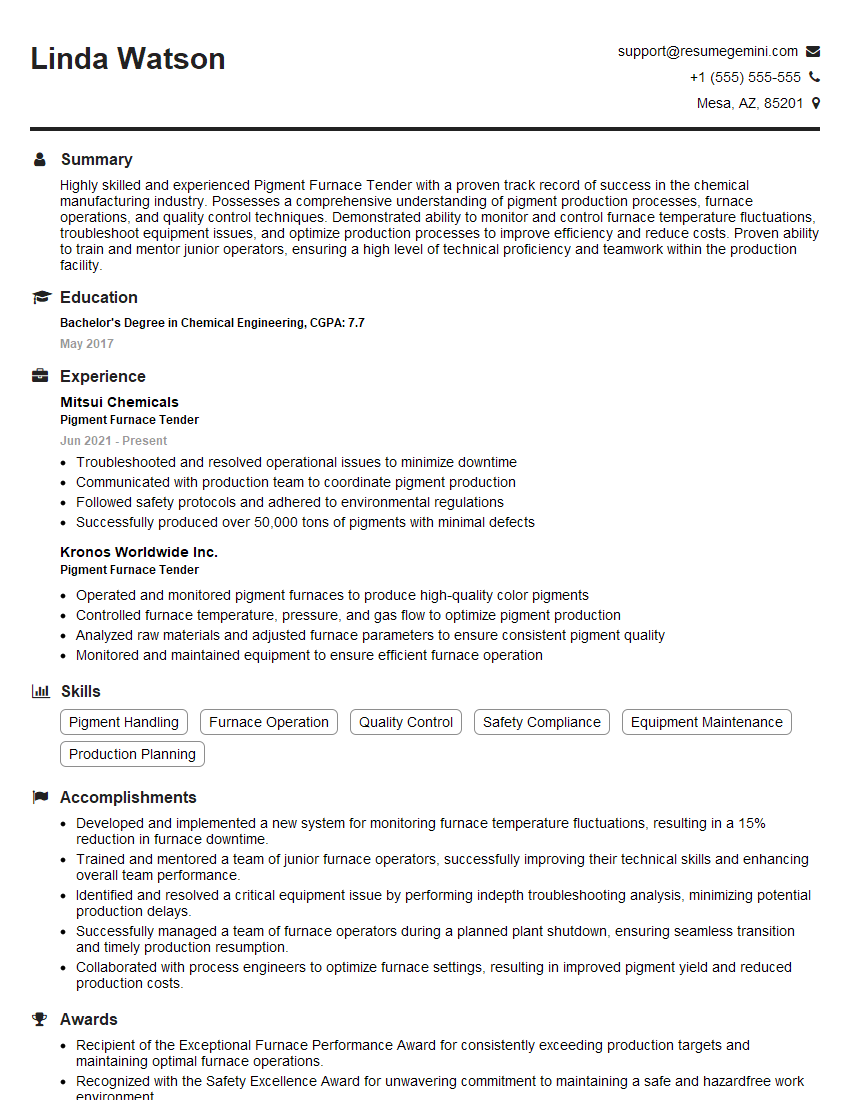

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pigment Furnace Tender

1. Describe the process of preparing the furnace for operation?

To prepare the furnace for operation, I would generally follow these steps:

- Check and ensure that the furnace is in good working condition and all necessary safety measures are in place.

- Load the furnace with the raw materials, ensuring proper mixing and proportions to achieve the desired pigment.

- Calibrate and adjust the furnace settings, such as temperature, pressure, and gas flow, according to the specified operating parameters.

- Conduct pre-heating to gradually raise the temperature and prepare the furnace for the main reaction.

2. Explain the different types of pigments produced in a furnace and their applications?

Inorganic Pigments

- Titanium Dioxide (TiO2): Used in paints, plastics, paper, and cosmetics for its high refractive index and brightness.

- Iron Oxides (Fe2O3, Fe3O4): Impart red, yellow, and black colors and are used in paints, ceramics, and construction materials.

Organic Pigments

- Phthalocyanines: Blue and green pigments used in paints, plastics, and printing inks.

- Azo Pigments: Wide range of colors, used in paints, textiles, and printing inks.

3. How do you ensure the quality of the pigment produced?

To ensure the quality of the pigment produced, I would:

- Monitor the furnace conditions throughout the process, including temperature, pressure, and gas composition.

- Take regular samples for quality control testing, checking for color consistency, particle size distribution, and other specifications.

- Make necessary adjustments to the furnace parameters based on the test results to maintain optimal conditions for pigment formation.

- Document the production process and quality control data for traceability and continuous improvement.

4. Describe the safety precautions that must be taken when operating a pigment furnace?

When operating a pigment furnace, I prioritize the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including heat-resistant clothing, gloves, and respiratory protection.

- Ensure adequate ventilation and exhaust systems to prevent exposure to harmful gases or fumes.

- Follow established safety protocols for handling and storing raw materials and finished products.

- Be aware of potential hazards such as high temperatures, pressure, and the presence of flammable or explosive materials.

- Receive proper training and regularly refresh safety knowledge to maintain a safe working environment.

5. How do you troubleshoot common problems that may occur during pigment furnace operation?

- Temperature Fluctuations: Adjust burner settings, check thermocouples, and inspect insulation.

- Pressure Issues: Inspect pressure gauges, clean filters, and check for leaks.

- Incomplete Reaction: Adjust furnace temperature, increase reaction time, or check raw material proportions.

- Pigment Contamination: Identify the source of contamination and implement measures to prevent it.

- Equipment Malfunctions: Follow established maintenance procedures, contact technical support, and ensure timely repairs.

6. What is the role of temperature control in pigment furnace operation?

Temperature control is crucial in pigment furnace operation for several reasons:

- Different pigments require specific temperature ranges for optimal formation and color development.

- Precise temperature control ensures consistent product quality, color accuracy, and desired properties.

- Overheating can lead to pigment degradation, discoloration, or even furnace damage.

- Proper temperature management helps optimize energy efficiency and reduce production costs.

7. How do you handle and store raw materials used in pigment furnace production?

- Dry Raw Materials: Store in moisture-proof containers, follow FIFO (First-In-First-Out) inventory management.

- Liquid Raw Materials: Keep in sealed containers, monitor storage temperature, and agitate periodically to prevent settling.

- Flammable or Hazardous Raw Materials: Store in separate, well-ventilated areas, comply with safety regulations.

- General Handling: Wear appropriate PPE, use proper equipment for handling and transportation, minimize exposure to air and moisture.

8. Describe the maintenance procedures for a pigment furnace?

- Regular Inspections: Check for leaks, wear and tear, and ensure proper operation of all components.

- Cleaning and Deburring: Remove any buildup or deposits to maintain heat transfer efficiency.

- Burner Maintenance: Inspect burners, clean nozzles, and adjust settings to optimize combustion.

- Electrical Maintenance: Check wiring, connections, and instrumentation for proper functioning.

- Lubrication: Lubricate moving parts to minimize friction and ensure smooth operation.

9. How do you optimize the energy efficiency of a pigment furnace?

- Insulation: Ensure proper insulation to minimize heat loss and improve temperature control.

- Burner Optimization: Adjust burner settings to achieve complete combustion and minimize fuel consumption.

- Heat Recovery Systems: Utilize waste heat from the furnace to preheat raw materials or generate steam.

- Process Optimization: Fine-tune the furnace operation parameters to minimize unnecessary energy usage.

- Regular Maintenance: Keep the furnace well-maintained to prevent energy-wasting issues.

10. What are the environmental considerations in pigment furnace operation?

- Emission Control: Implement pollution control measures to minimize the release of harmful gases and particulates.

- Waste Management: Properly dispose of furnace byproducts, such as slag and dust, in accordance with environmental regulations.

- Energy Efficiency: Optimize energy usage to reduce greenhouse gas emissions.

- Resource Conservation: Utilize raw materials efficiently and explore sustainable alternatives.

- Compliance with Regulations: Adhere to all applicable environmental laws and regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pigment Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pigment Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pigment Furnace Tenders are responsible for operating and maintaining furnaces used in the production of pigments. Their duties encompass a range of tasks, including:

1. Furnace Operation

This involves:

- Starting, stopping, and monitoring furnaces

- Adjusting temperature and pressure settings

- Ensuring proper combustion

2. Raw Material Handling

Pigment Furnace Tenders are responsible for:

- Loading raw materials into furnaces

- Inspecting raw materials for quality

- Storing materials safely

3. Product Monitoring

Their role includes:

- Sampling and testing pigments

- Ensuring product quality

- Inspecting finished products for defects

4. Equipment Maintenance

They are required to:

- Clean, lubricate, and repair furnaces

- Identify and troubleshoot equipment problems

- Assist in furnace repairs

Interview Tips

To ace an interview for the role of Pigment Furnace Tender, it’s crucial to:

1. Research the Company and the Role

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities of the Pigment Furnace Tender position.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating and maintaining furnaces, handling raw materials, and monitoring product quality. Share examples of your experience in a similar role.

3. Demonstrate Safety Awareness

Stress your commitment to safety and your understanding of the potential hazards associated with working in a furnace environment. Describe your experience with safety protocols.

4. Prepare for Technical Questions

Expect questions about furnace operation, raw material handling, product testing, and equipment maintenance. Be prepared to discuss your knowledge and experience in these areas.

5. Convey Communication and Teamwork Skills

Explain your ability to communicate effectively with colleagues, supervisors, and customers. Highlight your experience working in a team environment.

6. Show Enthusiasm for the Industry

Express your interest in the pigment industry and your eagerness to contribute to the company’s success. Demonstrate your knowledge of industry trends and advancements.

7. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the role. Prepare questions about the company’s culture, career development opportunities, and safety initiatives.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pigment Furnace Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pigment Furnace Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.