Are you gearing up for an interview for a Pigment Making Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pigment Making Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

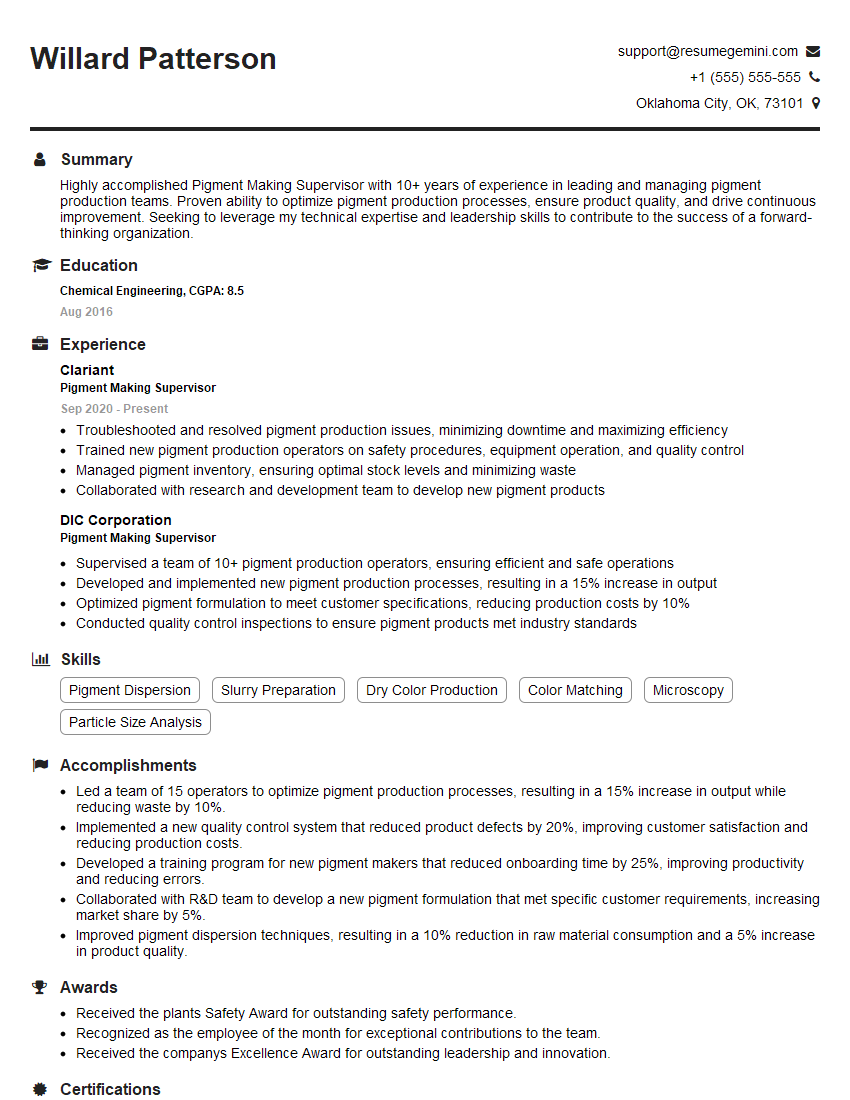

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pigment Making Supervisor

1. What are the key responsibilities of a Pigment Making Supervisor?

- Plan, schedule, and direct all activities related to pigment production

- Supervise and train production personnel

- Monitor production processes to ensure quality standards are met

- Troubleshoot production problems and implement corrective actions

- Maintain a safe and efficient work environment

2. What are the different types of pigments used in the industry?

Inorganic Pigments

- Metal oxides (e.g., titanium dioxide, iron oxide)

- Metal sulfides (e.g., cadmium sulfide, zinc sulfide)

- Metal carbonates (e.g., calcium carbonate, magnesium carbonate)

Organic Pigments

- Azo pigments

- Phthalocyanine pigments

- Anthraquinone pigments

3. What are the different processes involved in pigment production?

- Raw material preparation

- Mixing

- Grinding

- Drying

- Packaging

4. What are the key factors that affect pigment quality?

- Particle size and distribution

- Purity and composition

- Color strength and hue

- Lightfastness and durability

5. What are the common quality control tests performed on pigments?

- Particle size analysis

- Color measurement

- Chemical analysis

- Performance testing (e.g., lightfastness, durability)

6. What are the safety hazards associated with pigment production?

- Exposure to dust and chemicals

- Fire and explosion hazards

- Mechanical hazards (e.g., rotating machinery)

7. How do you maintain a safe and efficient work environment in a pigment production facility?

- Implement and enforce safety procedures

- Provide training on safety hazards and precautions

- Maintain a clean and organized work area

- Regularly inspect and maintain equipment

- Monitor employee health and safety

8. What are the latest trends and developments in pigment technology?

- Development of new, more sustainable pigments

- Improvements in pigment performance and durability

- Use of nanotechnology in pigment production

9. How do you stay up-to-date on the latest industry trends and best practices?

- Attend industry conferences and workshops

- Read trade publications and journals

- Network with other industry professionals

- Conduct research and development

10. What are your strengths and weaknesses as a Pigment Making Supervisor?

- Strong technical knowledge of pigment production processes

- Proven ability to lead and motivate a team

- Excellent communication and interpersonal skills

- Commitment to safety and quality

- Limited experience with new pigment technologies

- Need to improve time management skills

Strengths:

Weaknesses:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pigment Making Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pigment Making Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supervising the production process for pigments, ensuring that the desired quality standards are consistently met, is the central responsibility of the pigment making supervisor. They manage a team of operators, overseeing all aspects of production, from raw material preparation to finished product packaging.

1. Production Management

The pigment making supervisor’s core duty lies in meticulous production management. They establish and implement production schedules, allocating resources effectively to optimize output while adhering to quality specifications.

- Plans and executes production schedules based on customer orders and inventory levels.

- Monitors production processes, ensuring efficiency and adherence to established standards.

- Addresses production issues promptly, implementing corrective actions to minimize downtime and maintain productivity.

2. Quality Control

Upholding stringent quality standards is paramount. The supervisor conducts regular inspections of raw materials, in-process products, and finished pigments, evaluating their compliance with specifications.

- Inspects raw materials for adherence to established quality parameters.

- Monitors production processes to ensure conformity with quality standards.

- Conducts quality control tests on finished pigments to verify their performance and compliance.

3. Team Management

Effective team management is crucial for a smooth-running operation. The pigment making supervisor leads and motivates a team of operators, providing guidance, training, and support.

- Provides training and guidance to operators, ensuring their proficiency in production processes.

- Monitors operator performance, providing feedback and support for continuous improvement.

- Promotes a positive and collaborative work environment, fostering teamwork and open communication.

4. Process Improvement

Continuous improvement is key to maintaining efficiency and productivity. The pigment making supervisor actively seeks opportunities for process optimization, implementing innovative solutions.

- Evaluates production processes, identifying areas for improvement.

- Implements process improvements, such as automating tasks or optimizing workflow.

- Monitors the impact of process changes, adjusting as needed to maintain desired outcomes.

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some invaluable tips to help you ace your interview for a pigment making supervisor position:

1. Research the Company and Role

A well-informed candidate always stands out. Take the time to research the company’s background, their products and services, and the specific responsibilities of the pigment making supervisor role. This knowledge will enable you to demonstrate your understanding of the company and the position.

- Visit the company’s website and study the relevant sections.

- Read industry publications and news articles to stay up-to-date on current trends and technologies.

- Network with industry professionals and seek insights into the company and the role.

2. Quantify Your Experience

When describing your past experiences, it’s crucial to quantify your accomplishments and provide specific examples. Use numbers and metrics to convey the impact of your work and highlight your contributions.

- Instead of saying “I managed a team of operators,” say “I led a team of 10 operators, resulting in a 15% increase in production efficiency.”

- Quantify your quality control achievements, such as “Implemented a new inspection process that reduced product defects by 20%.”

- Highlight process improvements you’ve implemented, such as “Redesigned the workflow to streamline operations and reduce production time by 10%.”

3. Practice Your Answers

Preparing your answers to common interview questions will boost your confidence and delivery. Practice answering questions about your experience, skills, and qualifications related to the pigment making supervisor role.

- Rehearse your introduction and explain why you’re interested in the position.

- Prepare for questions about your production management, quality control, team leadership, and process improvement experience.

- Consider potential behavioral questions and prepare examples that showcase your relevant skills and abilities.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your engagement and interest in the company. Prepare questions related to the company’s plans, industry trends, or specific aspects of the pigment making process.

- Ask about the company’s growth strategy and how the pigment making department contributes to it.

- Inquire about any upcoming projects or initiatives that align with your skills and interests.

- Seek insights into the company’s quality control standards and how they ensure product excellence.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pigment Making Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!