Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pigment Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pigment Mixer so you can tailor your answers to impress potential employers.

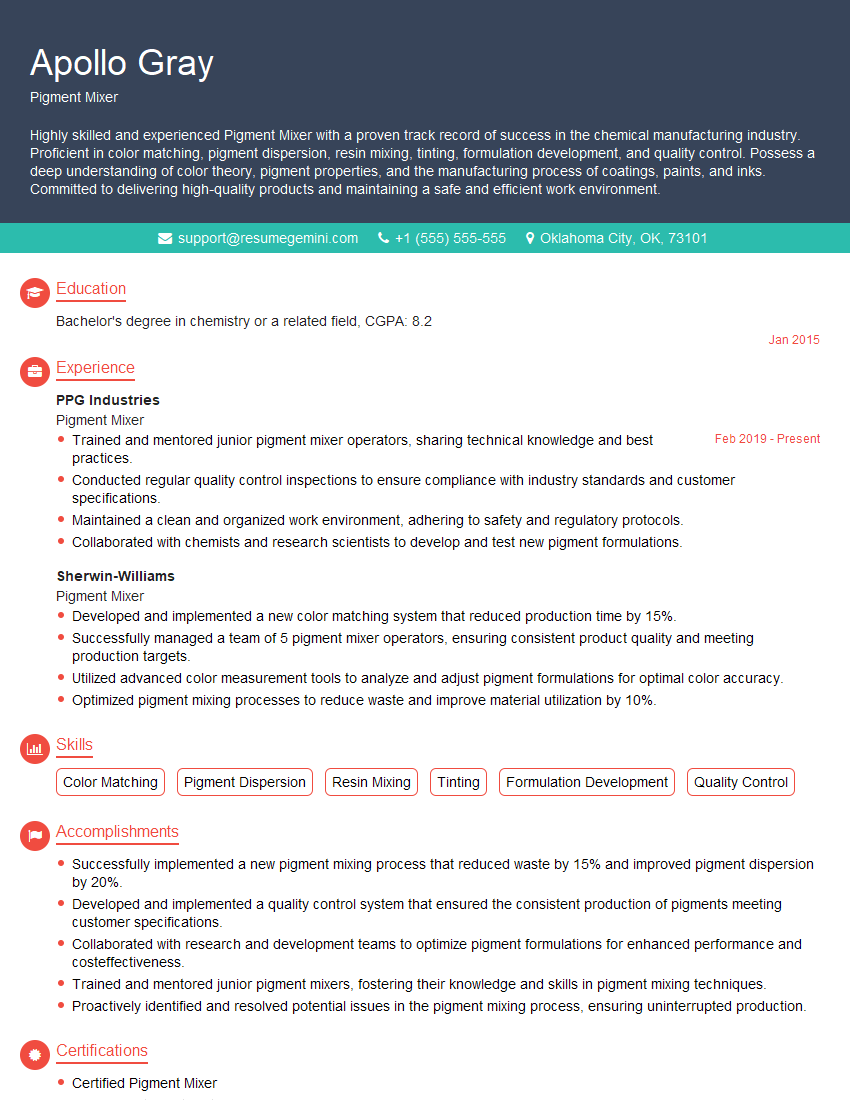

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pigment Mixer

1. What are the different types of pigments and their applications?

Pigments are natural or synthetic insoluble and colored powder that is used to enhance the visual appearance of plastic, paint, paper, etc. The main types of pigments are:

- Inorganic Pigments: These pigments are composed of mineral salts and are commonly used in industrial applications due to their resistance to heat and light.

- Organic Pigments: Derived from organic materials, these pigments offer a wide range of colors and are often used in printing, automotive paints, and cosmetics.

- Metallic Pigments: These pigments contain a metal such as aluminum or copper and impart a metallic finish when mixed with resins.

- Luminescent Pigments: Also known as glow-in-the-dark pigments, they absorb light energy and release it as visible light, making them suitable for safety signage and decorative purposes.

2. Describe the process of color matching in pigment mixing.

Matching Standard Colors

- Analyze the target color using a spectrophotometer to determine its spectral reflectance.

- Compare the reflectance data with a database of pigments to select a combination that closely matches the target.

- Adjust the proportions of each pigment based on the spectrophotometer readings.

Creating Custom Colors

- Start with a base color and gradually add small amounts of other pigments to adjust the hue, saturation, and brightness.

- Use a color mixing guide or software to determine the appropriate pigment ratios.

- Test the resulting color against the desired shade under different lighting conditions.

3. What are the key factors to consider when selecting pigments for a specific application?

When selecting pigments for a specific application, several key factors must be considered:

- Opacity: The ability of the pigment to block out the underlying surface.

- Tinting Strength: The amount of pigment required to produce a desired color intensity in a given medium.

- Lightfastness: The resistance of the pigment to fading or changing color when exposed to light.

- Chemical Resistance: The ability of the pigment to withstand exposure to chemicals, solvents, or acids.

- Temperature Stability: The ability of the pigment to maintain its color and properties under varying temperature conditions.

- Cost: The availability and cost of the pigment relative to the desired performance characteristics.

4. How do you ensure the consistency and quality of mixed pigments?

To ensure the consistency and quality of mixed pigments, I follow several key practices:

- Accurate Measurement: Use precise scales or measuring devices to ensure the correct proportions of each pigment.

- Thorough Mixing: Mix the pigments thoroughly using a high-shear mixer to achieve a uniform distribution and dispersion of particles.

- Quality Control: Regularly test the mixed pigments using spectrophotometry or colorimetric analysis to verify their color accuracy and other properties.

- Proper Storage: Store the pigments in a controlled environment to prevent contamination, moisture absorption, or degradation.

5. Describe the different techniques used to disperse pigments in various mediums.

- Ball Milling: A mechanical process that uses balls or beads to grind and disperse pigments into a liquid medium.

- Ultrasonic Dispersion: High-frequency sound waves are used to create cavitation bubbles that break down pigment agglomerates into smaller particles.

- High-Shear Mixing: A high-speed mixing device creates shear forces that break down pigment particles and promote their dispersion.

- Wetting Agents: These chemicals are added to reduce the surface tension between the pigment and the medium, aiding in dispersion.

6. How do you troubleshoot common problems encountered in pigment mixing, such as color variations or settling?

To troubleshoot common problems in pigment mixing, I follow a systematic approach:

- Identify the Problem: Clearly define the observed issue, whether it’s color variation, settling, or other defects.

- Analyze the Process: Review the pigment selection, mixing procedure, and equipment used to identify potential sources of error.

- Conduct Tests: Perform small-scale experiments to isolate the cause of the problem by varying factors such as pigment ratios, mixing time, or storage conditions.

- Implement Solutions: Based on the analysis and tests, make necessary adjustments to the mixing process or materials used to resolve the issue.

7. What are the safety precautions that should be taken when handling and mixing pigments?

When handling and mixing pigments, I adhere to strict safety precautions to ensure the well-being of myself and others:

- Personal Protective Equipment: Wear appropriate protective gear, including gloves, dust masks, and eye protection, to prevent exposure to hazardous substances.

- Ventilation: Ensure adequate ventilation in the mixing area to prevent the inhalation of harmful fumes or dust particles.

- Proper Storage: Store pigments in a well-labeled and controlled environment to prevent contamination or accidental ingestion.

- Training and Awareness: Receive thorough training on the specific pigments being handled, their potential hazards, and proper safety protocols.

8. How do you stay up-to-date with the latest advancements in pigment technology?

To stay abreast of the latest advancements in pigment technology, I engage in ongoing learning and professional development:

- Industry Publications: Subscribe to industry magazines, journals, and newsletters to stay informed about new products, research, and best practices.

- Conferences and Workshops: Attend industry conferences, seminars, and workshops to connect with experts, learn about emerging technologies, and exchange knowledge.

- Online Resources: Utilize online platforms, databases, and whitepapers to access up-to-date information on pigment properties, applications, and trends.

- Collaboration: Engage in discussions with colleagues, industry professionals, and researchers to share knowledge and learn from their experiences.

9. How do you handle working with pigments that have specific health or environmental regulations?

When working with pigments that have specific health or environmental regulations, I prioritize compliance and safety:

- Regulatory Awareness: Familiarize myself with all applicable regulations, including those related to hazardous materials, waste disposal, and emissions.

- Safe Handling: Implement strict procedures for handling and storing regulated pigments to minimize exposure and prevent contamination.

- Waste Disposal: Adhere to proper waste disposal methods as outlined by environmental regulations to protect the environment and human health.

- Documentation: Maintain accurate records of pigment usage, disposal, and any incidents related to regulated substances.

10. What is your understanding of the role of pigments in sustainable manufacturing?

In sustainable manufacturing, pigments play a significant role:

- Environmentally Friendly Pigments: Choose pigments that are derived from renewable resources or produced through eco-friendly processes to minimize environmental impact.

- Reduced Waste: Utilize high-quality pigments with good dispersion and tinting strength to reduce waste during the manufacturing process.

- Energy Efficiency: Select pigments that require less energy to disperse and incorporate into products, contributing to energy conservation.

- Recyclability: Consider the recyclability of pigments and their impact on the overall recyclability of the final product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pigment Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pigment Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Pigment Mixer plays a vital role in ensuring the accurate blending and preparation of pigments used in various industries. Their key responsibilities include:

1. Pigment Preparation and Mixing

Mixing and preparing pigments according to specified formulas and proportions using mixing equipment like blenders, mixers, and stirrers.

2. Quality Control and Testing

Monitoring and testing pigment samples to ensure they meet required quality standards and specifications using tools like spectrophotometers and viscometers.

3. Equipment Maintenance

Maintaining and cleaning mixing equipment, ensuring they are in good working condition and calibrated for accurate measurements.

4. Inventory Management

Maintaining inventory of pigments, dyes, and other raw materials, ensuring sufficient stock levels and timely replenishment.

5. Compliance with Regulations

Adhering to safety and environmental regulations related to pigment handling and disposal, ensuring compliance with industry standards.

6. Collaboration and Communication

Collaborating with production and quality control teams to understand pigment requirements and communicate any issues or deviations.

7. Troubleshooting

Identifying and resolving issues related to pigment mixing, equipment malfunction, or quality concerns, implementing corrective actions.

8. Record Keeping

Maintaining accurate records of pigment preparation, mixing parameters, and test results, ensuring traceability and quality documentation.

Interview Tips

To ace an interview for the Pigment Mixer role, here are some preparation tips and hacks:

1. Research the Company and Industry

Gain insights into the company’s operations, product line, and industry trends. Understanding the pigment mixing process and its applications will demonstrate your preparation.

2. Highlight Your Technical Skills

Emphasize your expertise in pigment mixing techniques, color theory, and quality control procedures. Showcase your proficiency in using blending equipment, such as mixers and viscometers.

3. Quantify Your Experience

Provide specific examples of your accomplishments as a Pigment Mixer. Quantify your results by stating the number of batches mixed, quality improvements achieved, or cost savings realized.

4. Demonstrate Attention to Detail

Stress your meticulous approach to pigment preparation and quality control. Highlight your ability to follow instructions precisely, maintain accurate records, and ensure product consistency.

5. Ask Informed Questions

Prepare thoughtful questions about the company’s pigment mixing practices, quality assurance systems, and opportunities for professional development. Asking insightful questions shows your engagement and interest in the role.

6. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivation. Rehearse your answers to questions about pigment mixing techniques, quality control procedures, and problem-solving abilities.

7. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your professionalism and respect for the interviewers.

Next Step:

Now that you’re armed with the knowledge of Pigment Mixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pigment Mixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini