Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pile Driving Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

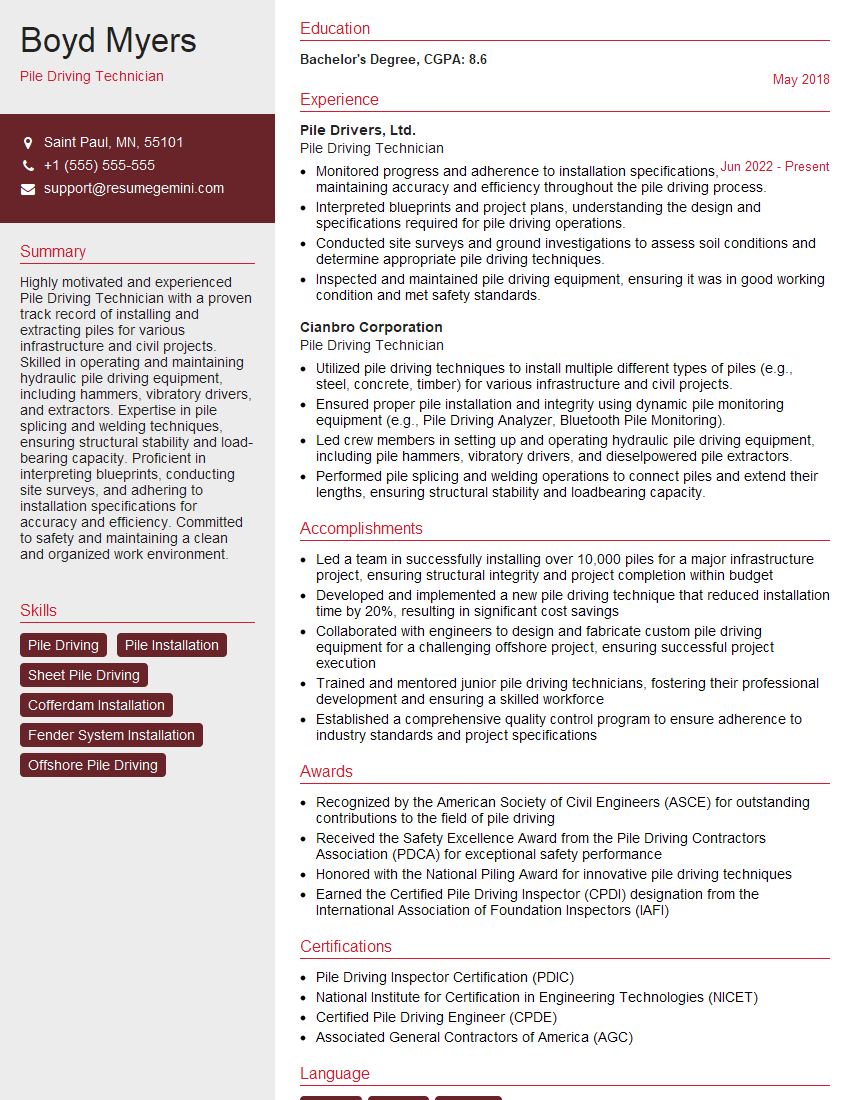

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pile Driving Technician

1. What are the different types of pile driving equipment and their applications?

- Impact hammers: These hammers use a weight to strike the pile, creating a downward force that drives the pile into the ground. Impact hammers are typically used for driving steel piles.

- Vibratory hammers: These hammers use a vibrating force to drive the pile into the ground. Vibratory hammers are typically used for driving steel or concrete piles.

- Diesel hammers: These hammers use a diesel engine to power a piston that strikes the pile. Diesel hammers are typically used for driving steel or concrete piles.

- Hydraulic hammers: These hammers use a hydraulic system to power a piston that strikes the pile. Hydraulic hammers are typically used for driving steel or concrete piles.

2. What are the factors that affect the choice of pile driving equipment?

subheading of the answer

- The type of pile being driven

- The soil conditions at the site

- The depth to which the piles need to be driven

- The environmental regulations that apply to the site

subheading of the answer

- The cost of the equipment

- The availability of the equipment

- The experience of the pile driving contractor

3. What are the safety precautions that must be taken when working on a pile driving project?

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, and earplugs.

- Stay clear of the pile driving equipment when it is in operation.

- Be aware of the overhead hazards, such as power lines and trees.

- Follow all safety instructions from the pile driving contractor.

4. What are the different types of pile driving defects and how can they be prevented?

- Overdriving: This occurs when the pile is driven too far into the ground, causing it to buckle or break.

- Underdriving: This occurs when the pile is not driven far enough into the ground, causing it to settle or fail.

- Misalignment: This occurs when the pile is not driven straight, causing it to lean or bend.

- Damage: This can occur during transportation, storage, or installation, and can weaken the pile or make it unusable.

5. What are the different methods of pile testing?

- Static load testing: This involves applying a static load to the pile and measuring the settlement.

- Dynamic load testing: This involves applying a dynamic load to the pile and measuring the response.

- Integrity testing: This involves using a sonic or ultrasonic device to assess the integrity of the pile.

6. What are the different types of pile driving contracts?

- Unit price contract: This type of contract pays the contractor a fixed price for each pile that is driven.

- Lump sum contract: This type of contract pays the contractor a fixed price for the entire project, regardless of the number of piles that are driven.

- Cost-plus contract: This type of contract pays the contractor the cost of the project plus a fixed percentage for profit.

7. What are the environmental regulations that apply to pile driving projects?

- The Clean Water Act

- The Clean Air Act

- The Endangered Species Act

- The National Environmental Policy Act

8. What are the latest trends in pile driving technology?

- The use of vibratory hammers to reduce noise and vibration

- The development of new pile driving equipment that is more efficient and environmentally friendly

- The use of pile driving simulations to optimize the design and construction of pile foundations

9. What are the challenges of working on a pile driving project?

- The weather can be a challenge, especially in cold or wet conditions.

- The ground conditions can be challenging, especially if the soil is soft or rocky.

- The noise and vibration from the pile driving equipment can be a nuisance to nearby residents and businesses.

- The environmental regulations can be complex and difficult to comply with.

10. What are your strengths and weaknesses as a pile driving technician?

- Strengths: I am a highly skilled and experienced pile driving technician with a strong understanding of the latest pile driving techniques and equipment.

- Weaknesses: I am sometimes impatient and can be frustrated when things don’t go according to plan.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pile Driving Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pile Driving Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pile Driving Technicians are responsible for the safe and efficient installation of piles into the ground, ensuring the stability and integrity of various structures such as buildings, bridges, and piers.

1. Pile Installation and Removal

Operate pile driving equipment to drive piles into the ground according to specifications.

- Select and assemble appropriate equipment for different pile types and soil conditions.

- Monitor pile penetration and adjust driving parameters to achieve optimal results.

- Remove piles when necessary, using appropriate techniques.

2. Equipment Maintenance and Repair

Perform regular maintenance on pile driving equipment to ensure optimal performance.

- Inspect and lubricate equipment, identifying and repairing any issues.

- Troubleshoot and resolve equipment malfunctions promptly.

- Maintain accurate records of equipment maintenance and repairs.

3. Site Preparation and Safety

Prepare job sites and implement safety measures to minimize hazards.

- Clear work areas, remove obstacles, and establish safe zones.

- Erect barricades and warning signs to protect workers and the public.

- Follow all safety regulations and protocols to ensure a safe work environment.

4. Collaboration and Communication

Collaborate with engineers, contractors, and other professionals to ensure project success.

- Attend project meetings and provide input on pile driving plans.

- Communicate effectively with supervisors, colleagues, and clients.

- Document project details, including pile installation data, equipment maintenance records, and safety observations.

Interview Tips

Preparing thoroughly for a Pile Driving Technician interview is crucial for success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest in the company and the pile driving industry by researching their projects, values, and recent developments.

- Visit the company website, read industry publications, and attend industry events.

- Identify key projects the company has worked on and highlight your skills that align with their needs.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience in pile driving.

- Quantify your accomplishments using specific numbers and metrics.

- Emphasize your experience with different types of pile driving equipment and soil conditions.

- Highlight your safety record and commitment to following industry regulations.

3. Prepare for Technical Questions

Anticipate technical questions related to pile driving techniques, equipment operation, and safety procedures.

- Review industry standards and best practices for pile installation.

- Be prepared to discuss different types of pile driving equipment and their applications.

- Practice answering questions about pile load testing, soil analysis, and troubleshooting techniques.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position.

- Inquire about the company’s current projects and future plans.

- Ask about opportunities for professional development and training.

- Seek clarification on any aspects of the job description or company culture that you find intriguing.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pile Driving Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!