Are you gearing up for a career in Pile Header? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pile Header and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

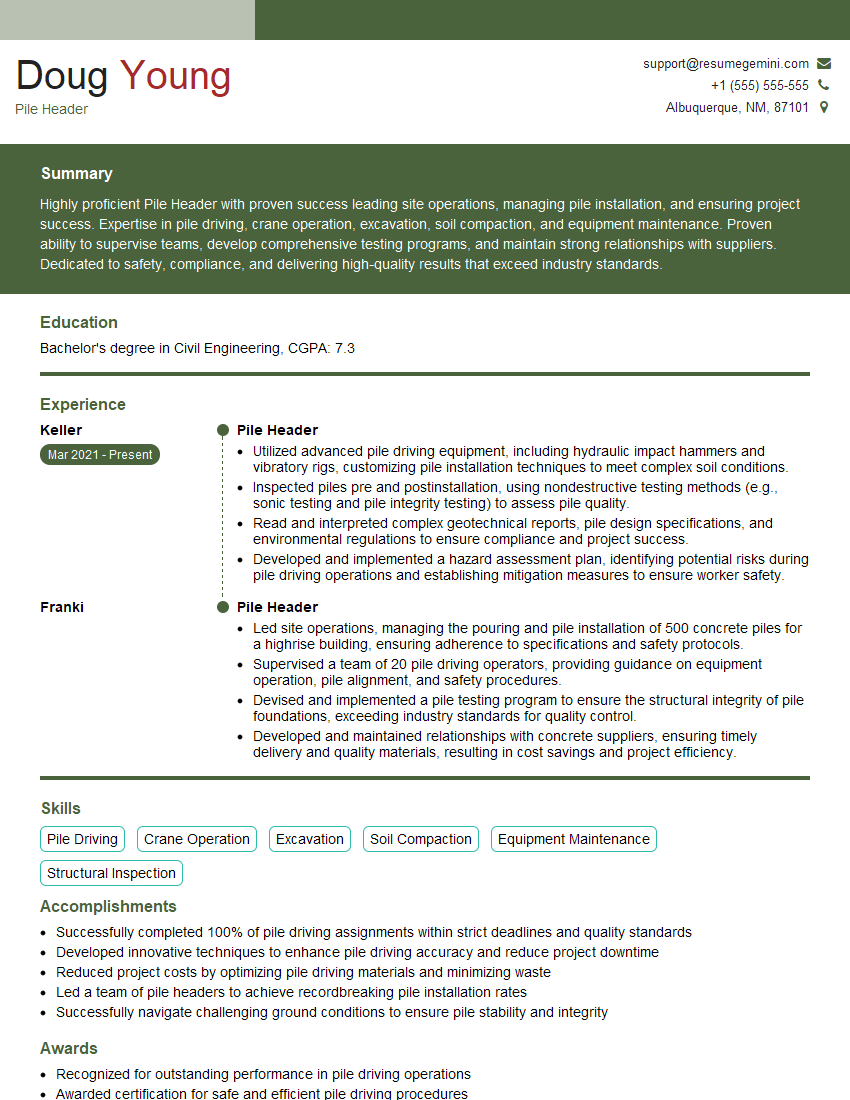

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pile Header

1. How do you determine the correct pile length for a given project?

To determine the correct pile length for a given project, I consider several factors:

- Soil conditions: The type of soil, its density, and the presence of any obstructions or weak layers.

- Load requirements: The weight of the structure and the anticipated loads it will carry.

- Building codes and regulations: The minimum pile length specified by local building codes.

- Geotechnical investigation: The results of a geotechnical investigation, including soil borings and testing.

2. What are the different methods used to install piles?

Driven Piles

- Impact driving: Using a pile driving hammer to drive the pile into the ground.

- Vibratory driving: Using a vibratory system to liquefy the soil and facilitate pile penetration.

Drilled and Cast-in-Place Piles

- Bored piles: Drilling a hole in the ground, placing the reinforcement cage, and pouring concrete.

- Continuous flight auger piles (CFA): Using a continuous flight auger to create a hole and simultaneously place concrete.

3. What are the common defects that can occur during pile installation and how do you prevent them?

Common defects during pile installation include:

- Pile misalignment: Maintaining proper alignment during driving or drilling.

- Pile damage: Using appropriate driving equipment and driving parameters.

- Concrete defects: Ensuring proper concrete mix design, pouring, and curing procedures.

- Load-bearing capacity issues: Verifying soil conditions and selecting the appropriate pile type and length.

4. How do you ensure the quality of the pile installation?

To ensure the quality of pile installation, I implement the following measures:

- Site inspection: Verifying site conditions and equipment before installation.

- Monitoring installation: Tracking pile progress, driving parameters, and concrete placement.

- Testing: Conducting pile load tests or dynamic testing to verify load-bearing capacity.

- Documentation: Maintaining detailed records of pile installation, including as-built drawings.

5. What are the environmental considerations in pile installation, and how do you minimize their impact?

- Noise and vibration: Using noise barriers, vibration dampers, and scheduled work hours.

- Dust and emissions: Implementing dust control measures and using low-emission equipment.

- Soil disturbance: Avoiding unnecessary soil excavation and implementing erosion control measures.

- Water pollution: Preventing runoff and spills of hazardous materials, and using spill containment systems.

6. What are the safety precautions you take during pile installation?

- Proper equipment operation: Ensuring all machinery is in good condition and operated by trained personnel.

- Personal protective equipment (PPE): Providing and enforcing the use of hard hats, safety glasses, gloves, and any other necessary PPE.

- Site safety measures: Establishing clear work zones, barricades, and warning signs.

- Emergency preparedness: Having a safety plan in place and conducting regular safety briefings.

7. What are the latest advancements in pile installation techniques?

- Sonic pile driving: Using sonic waves to drive piles with reduced noise and vibration.

- Micropiles: Installing small-diameter piles for limited access areas or retrofitting existing structures.

- Helical piles: Utilizing piles with helical blades for easier installation in dense soils.

- Expansive piles: Creating piles that expand in the ground after installation to increase load-bearing capacity.

8. How do you handle unexpected conditions during pile installation?

When encountering unexpected conditions during pile installation, I:

- Assess the situation: Evaluate the safety risks, potential impacts, and possible solutions.

- Consult with engineers: Seek guidance from geotechnical engineers or structural designers for technical advice.

- Modify installation methods: Adjust driving parameters, use different equipment, or consider alternative pile designs.

- Monitor and document: Closely monitor the installation process and record any changes or modifications made.

9. How do you ensure that the piles meet the design specifications and load requirements?

- Pile testing: Conducting load tests or dynamic testing to verify the pile’s load-bearing capacity.

- Inspection and documentation: Visually inspecting piles for any defects and maintaining detailed records of installation parameters.

- Quality control: Implementing a quality control plan to monitor materials, workmanship, and adherence to specifications.

- Collaboration with engineers: Working closely with geotechnical and structural engineers to ensure design compliance.

10. How do you stay updated on the latest industry best practices and advancements in pile installation techniques?

- Continuing education: Attending conferences, workshops, and training programs.

- Professional development: Reading industry publications, technical journals, and online resources.

- Networking: Engaging with industry professionals, suppliers, and contractors to exchange knowledge and insights.

- Research and innovation: Exploring new technologies and methods to improve installation efficiency and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pile Header.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pile Header‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pile Headers are responsible for the safe and efficient operation of pile driving equipment to install piles for various construction projects. They play a critical role in ensuring the structural integrity and stability of foundations.

1. Equipment Operation

Operate and maintain pile driving equipment, including hydraulic hammers, diesel hammers, and vibratory drivers.

- Monitor equipment performance and make necessary adjustments.

- Perform routine maintenance and repairs to ensure optimal functionality.

2. Pile Installation

Install piles according to project specifications and engineering drawings.

- Determine pile placement, orientation, and depth.

- Position and secure the pile using guidance systems.

- Drive the pile to the required depth and load-bearing capacity.

3. Quality Control

Inspect piles before, during, and after installation to ensure compliance with quality standards.

- Verify pile dimensions, material properties, and surface conditions.

- Record installation data and maintain accurate documentation.

- Collaborate with engineers and inspectors to address any discrepancies.

4. Safety and Environmental Compliance

Adhere to strict safety protocols and regulations while operating machinery.

- Use appropriate personal protective equipment (PPE).

- Inspect work areas for potential hazards and implement safety measures.

- Follow environmental regulations related to noise, dust, and waste disposal.

Interview Tips

To ace the interview for a Pile Header position, candidates should prepare thoroughly and demonstrate their skills and experience relevant to the job responsibilities. Here are some tips to help candidates excel in the interview:

1. Research the Company and Project

Familiarize yourself with the company’s profile, project details, and any specific requirements for the pile driving operation. This will showcase your genuine interest in the position and your ability to align your skills with the project’s needs.

2. Highlight Relevant Experience and Skills

Emphasize your experience in pile driving, equipment operation, and quality control. Provide specific examples of projects where you have successfully installed piles and ensured their structural integrity. Discuss your knowledge of pile driving techniques, equipment maintenance, and safety protocols.

3. Demonstrate Safety Consciousness

Highlight your commitment to safety and adherence to industry regulations. Explain how you prioritize hazard identification, risk assessment, and proper use of PPE. Emphasize your understanding of safety measures related to pile driving operations and your role in maintaining a safe work environment.

4. Prepare for Technical Questions

Be prepared to answer technical questions about pile driving equipment, pile installation methods, and quality control procedures. Practice explaining the principles of pile driving, the different types of piles and their applications, and the factors that influence pile capacity.

5. Show Enthusiasm and Motivation

Express your enthusiasm for working in the construction industry and your interest in the specific role of a Pile Header. Highlight your eagerness to contribute to the success of the project and your commitment to delivering high-quality work. Show that you are passionate about pile driving and eager to grow in this field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pile Header, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pile Header positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.