Feeling lost in a sea of interview questions? Landed that dream interview for Pill Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pill Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

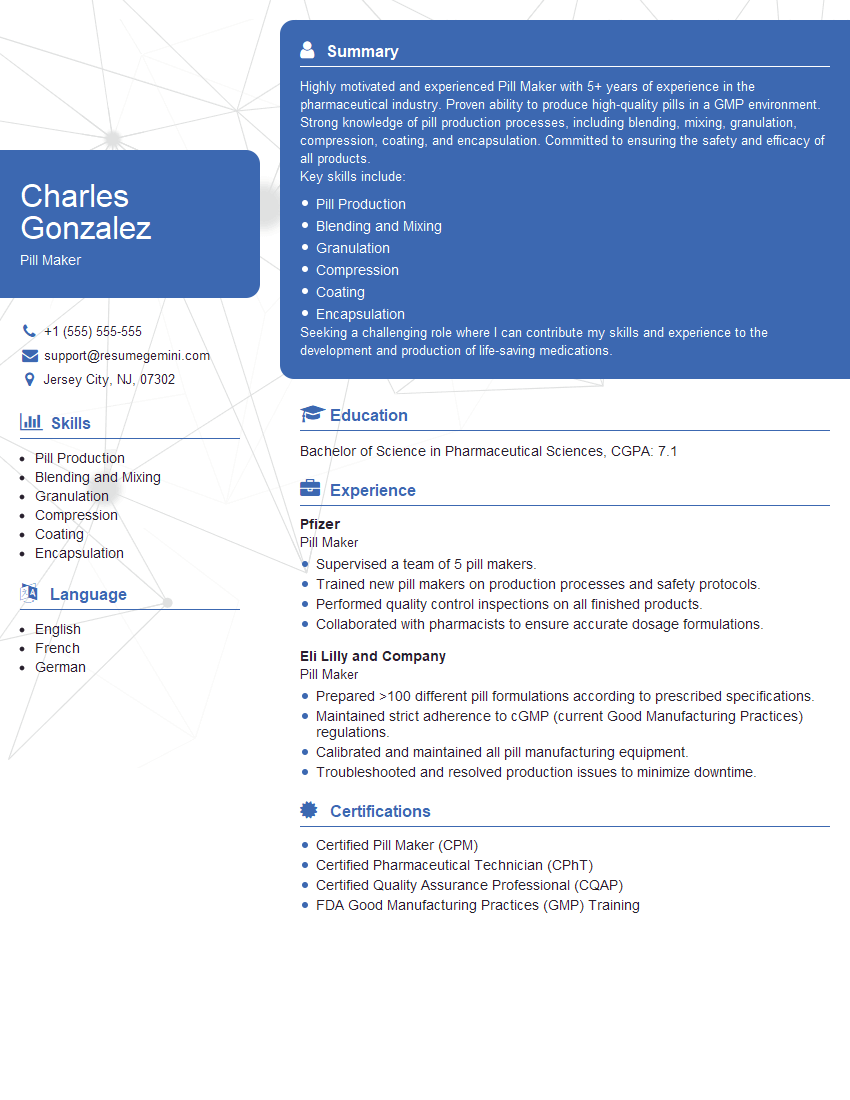

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pill Maker

1. Describe the process of formulating and developing a new pill?

The process of formulating and developing a new pill involves several key steps:

- Pre-formulation: This stage includes characterizing the drug substance, excipients selection, and determining the drug’s physicochemical properties.

- Formulation development: Here, different formulations are prepared and evaluated based on factors like drug solubility, dissolution rate, and stability.

- Optimization: The formulation is optimized to achieve desired drug release and bioavailability.

- Scale-up and manufacturing: The optimized formulation is scaled up for production, considering factors like equipment and process validation.

- Post-manufacturing: The manufactured pills undergo quality control tests to ensure compliance with specifications.

2. How would you ensure the quality and consistency of the pills produced?

Quality control measures

- Establishing specifications for raw materials and finished products.

- Implementing Good Manufacturing Practices (GMP) and quality control procedures.

- Performing in-process and final product testing.

Consistency

- Optimizing process parameters and equipment.

- Using standardized operating procedures (SOPs).

- Regularly monitoring and adjusting the production process.

3. What techniques are used to improve the bioavailability and absorption of oral pills?

Various techniques can be employed to enhance bioavailability and absorption:

- Modifying drug particle size: Reducing particle size increases surface area for dissolution and absorption.

- Using excipients: Certain excipients, like surfactants and penetration enhancers, can improve drug solubility and absorption.

- Controlled-release formulations: These formulations release the drug gradually, optimizing absorption and reducing side effects.

- Taste masking: Coating or encapsulation techniques are used to mask unpleasant tastes and enhance patient compliance.

4. Explain the importance of stability testing in pill development?

Stability testing is crucial for several reasons:

- Ensuring drug potency and efficacy: It evaluates the stability of the drug substance and product over time.

- Assessing shelf life: Stability testing helps determine the appropriate storage conditions and expiration date.

- Compliance with regulations: Stability testing data is required by regulatory agencies to approve and market the product.

- Predicting long-term performance: It allows manufacturers to anticipate potential degradation pathways and implement countermeasures.

5. What is the role of encapsulation in pill manufacturing?

Encapsulation techniques provide various benefits in pill manufacturing:

- Controlled release: Encapsulation materials can be designed to release the drug at a specific rate or target specific areas.

- Taste masking: Encapsulation can mask unpleasant tastes, making pills more palatable.

- Protection from degradation: Encapsulation materials can protect the drug from environmental factors like moisture or light.

- Enhanced bioavailability: Encapsulation can improve drug solubility and absorption.

6. Describe the different types of pill coating and their purposes?

Various pill coating types are used for specific purposes:

- Sugar coating: Provides a smooth and aesthetically pleasing finish, masks taste, and protects from moisture.

- Film coating: A thin, polymer-based coating that enhances stability, modifies drug release, and masks taste.

- Enteric coating: Protects the drug from stomach acid, allowing it to dissolve in the intestine.

- Sustained-release coating: Controls drug release over an extended period.

7. Explain the concept of bioavailability and factors that affect it?

Bioavailability refers to the fraction of an administered drug that reaches systemic circulation.

Factors affecting bioavailability

- Drug formulation: Factors like particle size, solubility, and drug release rate can impact bioavailability.

- Physiological factors: Absorption, metabolism, and excretion can vary among individuals.

- Drug-drug interactions: Certain drugs can interfere with the bioavailability of others.

- Route of administration: Oral bioavailability is typically lower than other routes due to first-pass metabolism.

8. Describe the role of excipients in pill formulation and their selection criteria?

Excipients play various roles in pill formulation:

- Binders and fillers: Hold the ingredients together and provide bulk.

- Lubricants: Prevent sticking during manufacturing and improve flowability.

- Disintegrants: Promote pill breakdown after ingestion.

- Glidants: Enhance powder flowability and reduce friction.

Selection criteria

- Compatibility with the drug

- Required functionality

- Cost and availability

9. What are the common challenges faced during pill manufacturing and how can they be addressed?

Challenges

- Scaling up production: Maintaining consistency and quality during large-scale manufacturing can be challenging.

- Ensuring drug stability: Protecting the drug from degradation during processing and storage is crucial.

- Meeting regulatory requirements: Adhering to GMP and other regulations is essential.

Solutions

- Process optimization: Validating processes and optimizing equipment to ensure consistency.

- Proper storage conditions: Implementing appropriate packaging and storage protocols to maintain drug stability.

- Regulatory compliance: Establishing and maintaining a quality management system to meet regulatory requirements.

10. Describe the advancements in pill manufacturing technology and their potential impact?

Advancements

- 3D printing: Enables precise and customized pill production.

- Nanotechnology: Enhances drug delivery and targeting.

- Smart pills: Incorporate sensors or electronics to monitor drug absorption and patient compliance.

Impact

- Personalized medicine: Tailored pills based on individual patient needs.

- Improved drug delivery: Enhanced absorption, reduced side effects, and increased efficacy.

- Patient convenience: Smart pills can provide real-time feedback and improve medication adherence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pill Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pill Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pill Maker is responsible for various tasks in a pharmaceutical manufacturing setting, including:

1. Pill Production and Equipment Operation

Manufacturing and producing pills using a variety of equipment.

- Operate pill-making machines to produce tablets, capsules, or other dosage forms.

- Monitor and maintain equipment, ensuring proper functioning and adherence to safety standards.

2. Quality Assurance and Control

Ensuring the quality and safety of the pills produced.

- Perform quality control tests on raw materials and finished products to ensure compliance with specifications.

- Monitor production processes and adjust parameters as needed to maintain product quality.

3. Process Optimization and Improvement

Continuously improving the pill-making processes.

- Identify and implement opportunities for process optimization to increase efficiency and productivity.

- Troubleshoot production issues, analyze data, and make recommendations for improvements.

4. Safety and Compliance

Adhering to safety protocols and regulatory requirements.

- Follow established safety protocols, including wearing appropriate personal protective equipment.

- Maintain a clean and organized work environment, adhering to Good Manufacturing Practices (GMP) and regulatory standards.

Interview Tips

To help candidates ace the interview for a Pill Maker position, here are some tips and preparation strategies:

1. Research the Company and Role

Demonstrate your interest in the company and role by researching their values, products, and the specific responsibilities of a Pill Maker within their organization.

- Review the company’s website, LinkedIn page, and any recent news articles or industry reports.

- Read the job description carefully to understand the key requirements and expectations.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience in pill production, quality control, or a related field. Quantify your accomplishments and provide specific examples to showcase your skills.

- Quantify your results, such as increasing production efficiency by a specific percentage or reducing product defects.

- Provide specific examples of how you have troubleshooting production issues and implemented process improvements.

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you deliver clear and concise responses.

- Prepare for questions about your experience, skills, and motivation for applying to the role.

- Rehearse your answers to behavioral questions using the STAR method (Situation, Task, Action, Result).

4. Be Enthusiastic and Professional

Show your enthusiasm for the role and the pharmaceutical industry during the interview. Maintain a professional demeanor and demonstrate your communication and interpersonal skills.

- Be yourself and show your genuine interest in the position.

- Dress appropriately and arrive on time for the interview.

5. Ask Thoughtful Questions

Ask thoughtful questions at the end of the interview to show your engagement and interest in the role. This also gives you an opportunity to clarify any remaining questions.

- Ask about the company’s growth plans and how the role fits into those plans.

- Inquire about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pill Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.