Are you gearing up for a career in Pilot Fuel Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pilot Fuel Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

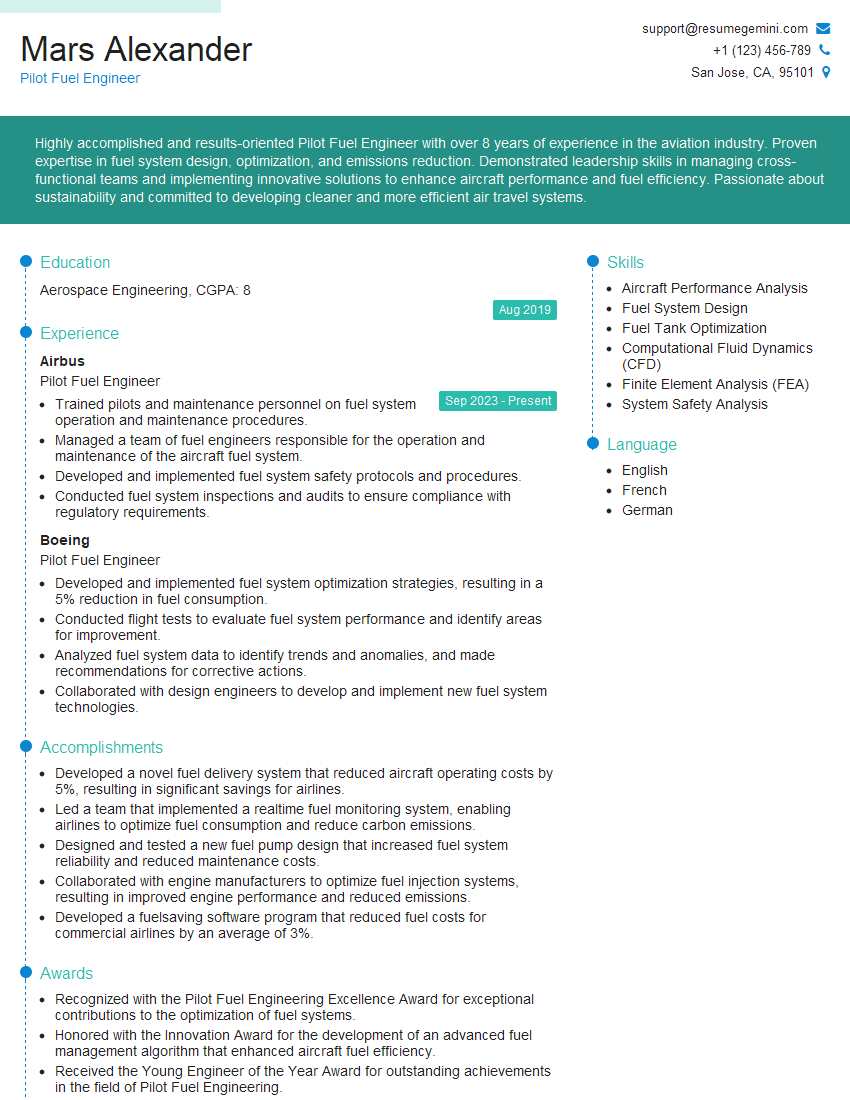

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pilot Fuel Engineer

1. Explain the principles of engine combustion and its significance in aircraft fuel design?

Principles of Engine Combustion

- Intake: Air and fuel are mixed in the intake manifold.

- Compression: The mixture is compressed in the cylinder by the piston.

- Ignition: A spark plug ignites the compressed mixture.

- Expansion: The burning mixture expands, driving the piston down and producing power.

- Exhaust: The burned gases are expelled through the exhaust valve.

Significance in Aircraft Fuel Design

- Combustion efficiency: Fuels need to optimize engine combustion to maximize thrust and minimize emissions.

- Ignition characteristics: Fuels must have appropriate ignition properties to support reliable engine starts and smooth operation.

- Thermal stability: Fuels must be thermally stable to withstand high temperatures and pressures encountered during combustion.

2. Discuss the role of fuel additives in aviation fuel.

Anti-icing Additives

- Prevent ice formation in fuel lines and filters.

- Enhance fuel flow and engine performance.

Antioxidants

- Inhibit fuel degradation and oxidation.

- Extend fuel storage life and stability.

Lubricity Additives

- Reduce friction and wear on engine components.

- Enhance fuel pump and injector performance.

3. Describe the methods used for testing and evaluating aircraft fuel quality.

- ASTM Standards: Adherence to American Society for Testing and Materials (ASTM) specifications for various fuel properties.

- Physical Tests: Assessing density, viscosity, flash point, etc.

- Chemical Tests: Determining composition, sulfur content, and other chemical characteristics.

- Engine Testing: Evaluating fuel performance in actual engine conditions.

4. Explain the concept of fuel trim and its importance in aircraft operations.

- Fuel trim adjusts the fuel flow rate to maintain optimal engine performance.

- It compensates for variations in engine conditions, such as altitude, temperature, and load.

- Proper fuel trim ensures efficient engine operation, reduces fuel consumption, and minimizes emissions.

5. Discuss the challenges associated with designing and managing fuel systems for commercial aircraft.

- Space constraints: Limited space on aircraft requires efficient fuel tank design and positioning.

- Fuel weight optimization: Reducing fuel weight while ensuring adequate range and payload capacity.

- Safety considerations: Adhering to strict regulations and implementing safety measures to prevent fuel leaks and fires.

- Environmental impact: Designing fuel systems that minimize emissions and reduce noise levels.

6. Explain the principles of fuel circulation and management in turbofan engines.

Fuel Circulation

- Fuel is pumped from the tanks to the engine through a fuel control unit.

- The fuel control unit regulates fuel flow based on engine requirements.

Fuel Management

- Fuel is distributed to different sections of the engine, including the combustor, bypass ducts, and afterburner.

- Fuel quantity and flow rates are monitored and adjusted to optimize engine performance and efficiency.

7. Discuss the importance of fluid dynamics in the design of aircraft fuel systems.

- Fuel flow analysis: Understanding the behavior of fuel as it flows through pipes, tanks, and pumps.

- Pressure drop calculations: Determining pressure losses in fuel lines to ensure proper fuel delivery.

- Aerodynamic effects: Considering the impact of fuel flow on the aircraft’s stability and handling characteristics.

8. Describe the factors that influence the selection of aviation fuel grades and their impact on engine performance.

- Engine type: Turbine or piston engines have different fuel requirements.

- Aircraft operating conditions: Altitude, temperature, and flight duration affect fuel selection.

- Fuel availability and cost: Availability and pricing of different fuel grades must be considered.

- Environmental regulations: Emissions standards dictate the use of specific fuel grades.

9. Explain the process of fuel bunkering and the safety protocols involved.

- Coordination: Planning and scheduling fuel delivery with ground personnel.

- Equipment setup: Setting up hoses, pumps, and safety barriers.

- Fuel transfer: Monitoring and controlling fuel flow to prevent spills and overfilling.

- Verification: Measuring fuel quantity and verifying fuel quality.

- Safety precautions: Wearing appropriate protective gear, using grounding equipment, and adhering to emergency procedures.

10. Discuss the latest advancements in fuel technology and their potential impact on aircraft performance and sustainability.

- Biofuels: Alternative fuels derived from renewable sources, reducing emissions and dependency on fossil fuels.

- Electric propulsion: Hybrid and fully electric aircraft, eliminating fuel combustion and emissions.

- Advanced fuel additives: Enhancing fuel efficiency, reducing carbon deposits, and improving engine performance.

- Data analytics: Using real-time data to optimize fuel consumption and engine maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pilot Fuel Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pilot Fuel Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pilot Fuel Engineer is responsible for designing, developing, and managing fuel systems for aircraft. This involves working with a team of engineers to design and test fuel systems, ensuring that they meet safety and performance standards. Key job responsibilities include:

1. Design and development of fuel systems

This involves working with a team of engineers to design and test fuel systems, ensuring that they meet safety and performance standards. The engineer must have a strong understanding of fluid dynamics, thermodynamics, and materials science.

2. Testing and evaluation of fuel systems

This involves testing and evaluating fuel systems to ensure that they meet safety and performance standards. The engineer must have a strong understanding of testing procedures and data analysis.

3. Troubleshooting and repair of fuel systems

This involves troubleshooting and repairing fuel systems that are not functioning properly. The engineer must have a strong understanding of fuel system components and repair procedures.

4. Management of fuel system maintenance

This involves managing the maintenance of fuel systems to ensure that they are operating safely and efficiently. The engineer must have a strong understanding of maintenance procedures and scheduling.

Interview Tips

To prepare for an interview for a Pilot Fuel Engineer position, it is important to:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position. You should also be able to speak to your qualifications and experience in relation to the job requirements.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview. Some common interview questions for Pilot Fuel Engineers include:

- What is your experience in designing and developing fuel systems?

- What is your experience in testing and evaluating fuel systems?

- What is your experience in troubleshooting and repairing fuel systems?

- What is your experience in managing fuel system maintenance?

3. Be prepared to discuss your salary expectations

It is important to be prepared to discuss your salary expectations during the interview. You should research the average salary for Pilot Fuel Engineers in your area and be prepared to negotiate.

4. Bring a portfolio of your work

A portfolio of your work can help you to showcase your skills and experience to the interviewer. This could include examples of your designs, test results, or repair work.

Next Step:

Now that you’re armed with the knowledge of Pilot Fuel Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pilot Fuel Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini