Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pinion Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

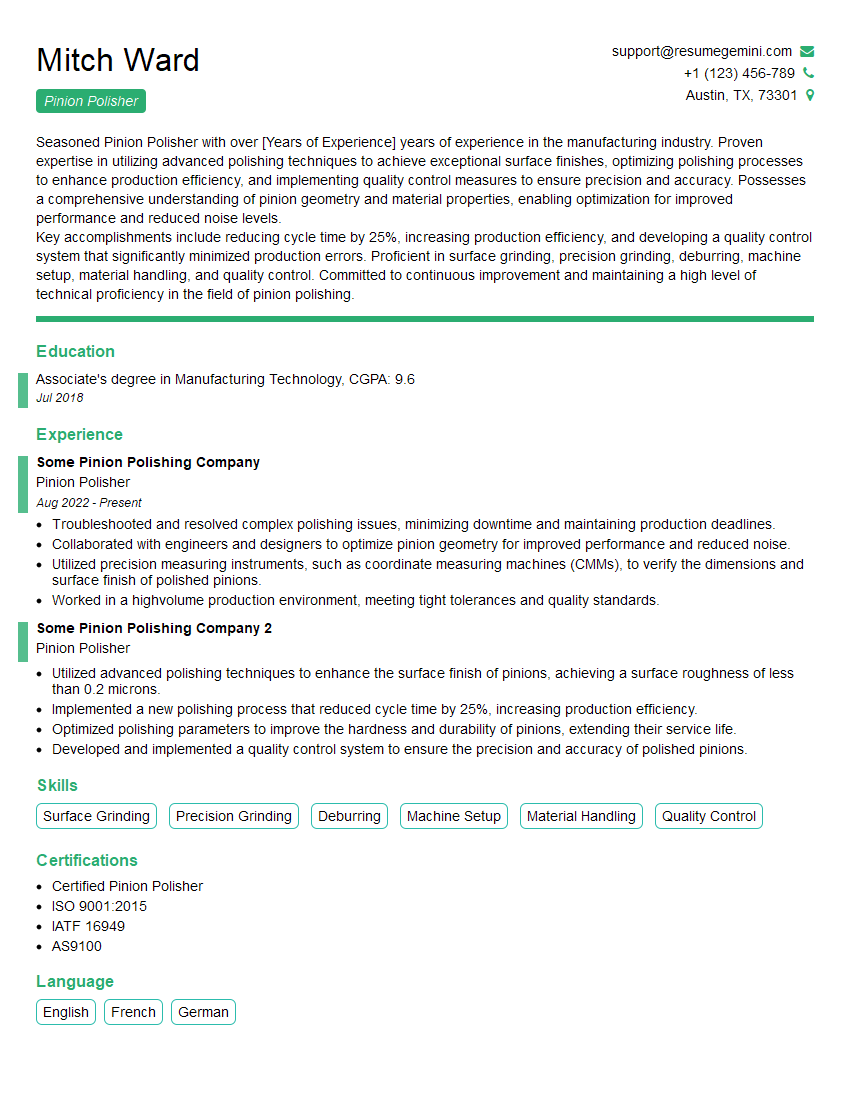

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pinion Polisher

1. Explain the process of polishing pinions.

- Begin by cleaning the pinion to remove any dirt or debris.

- Apply a polishing compound to the pinion and use a polishing wheel to remove any burrs or imperfections.

- Continue polishing until the pinion is smooth and shiny.

- Inspect the pinion under a microscope to ensure it is free of any defects.

- Apply a protective coating to the pinion to prevent corrosion.

2. What are the different types of polishing compounds available for pinions?

Water-based compounds:

- Less aggressive and produce a finer finish.

- Ideal for softer materials, such as aluminum or brass.

Oil-based compounds:

- More aggressive and produce a quicker finish.

- Ideal for harder materials, such as steel or titanium.

Diamond compounds:

- Extremely aggressive and produce the finest possible finish.

- Only used for very hard materials, such as ceramic or carbide.

3. What are the common defects that can occur during pinion polishing?

- Scratches or gouges

- Burrs or imperfections

- Corrosion or pitting

- Lack of shine or reflectivity

- Excessive wear or damage

4. How do you ensure that polished pinions meet the required quality standards?

- Inspect the pinions under a microscope to identify any defects.

- Measure the pinions to ensure they meet the specified dimensions.

- Test the pinions on a machine to ensure they operate smoothly and efficiently.

- Maintain a log of all inspections and tests performed.

- Follow established quality control procedures.

5. What are the safety precautions that must be taken when polishing pinions?

- Wear appropriate personal protective equipment, such as gloves, eye protection, and a dust mask.

- Ensure the polishing machine is properly guarded and maintained.

- Avoid contact with the polishing compound or wheel.

- Do not operate the polishing machine when it is unattended.

- Follow all safety protocols and procedures.

6. How do you troubleshoot common problems that arise during pinion polishing?

- If the pinion is not polishing evenly, adjust the pressure or speed of the polishing wheel.

- If the pinion is overheating, use a water-based polishing compound or reduce the pressure on the polishing wheel.

- If the polishing compound is not adhering to the pinion, try using a different type of compound or cleaning the pinion more thoroughly.

- If the pinion is becoming damaged, stop polishing and inspect the pinion for defects.

7. What is the importance of maintaining a clean and organized work area?

- Reduces the risk of accidents, such as slips and falls.

- Helps to prevent contamination of the work area and the pinions being polished.

- Improves efficiency and productivity.

- Creates a positive and professional work environment.

8. How do you stay up-to-date on the latest techniques and materials for pinion polishing?

- Attend industry conferences and workshops.

- Read trade publications and articles.

- Consult with other pinion polishing professionals.

- Experiment with different techniques and materials.

9. What are your strengths as a Pinion Polisher?

- Skilled in all aspects of pinion polishing, including cleaning, polishing, and inspecting.

- Have a strong understanding of the different types of polishing compounds and their applications.

- Capable of troubleshooting common problems and ensuring that polished pinions meet the required quality standards.

- Maintain a clean and organized work area and follow all safety protocols.

- Eager to learn new techniques and materials to improve my skills.

10. What are your career goals and how do you see this position helping you achieve them?

- My long-term goal is to become a lead pinion polisher and eventually start my own pinion polishing business.

- This position will provide me with the opportunity to develop my skills and gain valuable experience in the field.

- I am confident that I can contribute to your company’s success and help your team achieve its goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pinion Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pinion Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pinion Polisher is responsible for polishing pinions, which are small gears that are used in a variety of machines, including watches, clocks, and other precision instruments. The Pinion Polisher’s primary objective is to ensure that the pinions are smooth and free of defects, which can affect the accuracy and performance of the machine.

1. Polishing Pinions

The Pinion Polisher uses a variety of tools and techniques to polish pinions. These tools may include a polishing wheel, a buffing wheel, and a variety of abrasive compounds. The Pinion Polisher must be able to operate these tools safely and effectively to achieve the desired results.

- Operate polishing wheels and buffing wheels to remove burrs and imperfections from pinions

- Use abrasive compounds to polish pinions to a high shine

- Inspect pinions for defects using a variety of tools, such as microscopes and gauges

2. Maintaining Equipment

The Pinion Polisher must also be able to maintain the equipment that is used to polish pinions. This may include cleaning and lubricating the equipment, as well as replacing worn or damaged parts.

- Clean and lubricate polishing and buffing equipment

- Replace worn or damaged parts on equipment

- Calibrate and adjust equipment to ensure accuracy

3. Quality Control

The Pinion Polisher must also be able to perform quality control checks on the pinions that are being polished. This may involve inspecting the pinions for defects, such as scratches, burrs, or other imperfections.

- Inspect pinions for defects using a variety of tools, such as microscopes and gauges

- Reject pinions that do not meet quality standards

- Maintain records of quality control checks

4. Safety

The Pinion Polisher must also be able to follow safety procedures and regulations. This may involve wearing appropriate safety gear, such as gloves, safety glasses, and a respirator.

- Follow all safety procedures and regulations

- Wear appropriate safety gear, such as gloves, safety glasses, and a respirator

- Handle chemicals and other hazardous materials safely

Interview Tips

To help candidates ace their interview for a Pinion Polisher position, here are some tips and preparation hacks:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, social media pages, and other online resources.

- Visit the company’s website to learn about its history, products, and services.

- Check the company’s social media pages to see what it is posting about.

- Read articles and news stories about the company to get a sense of its reputation and industry standing.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Write down a list of common interview questions.

- Practice answering each question out loud.

- Time yourself to make sure that your answers are concise.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”

- Write down a list of questions to ask the interviewer.

- Practice asking your questions out loud.

- Make sure that your questions are relevant to the position and the company.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive for your interview on time, or even a few minutes early.

- Make eye contact with the interviewer and shake their hand firmly.

Next Step:

Now that you’re armed with the knowledge of Pinion Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pinion Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini