Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pinked Edge Sewing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

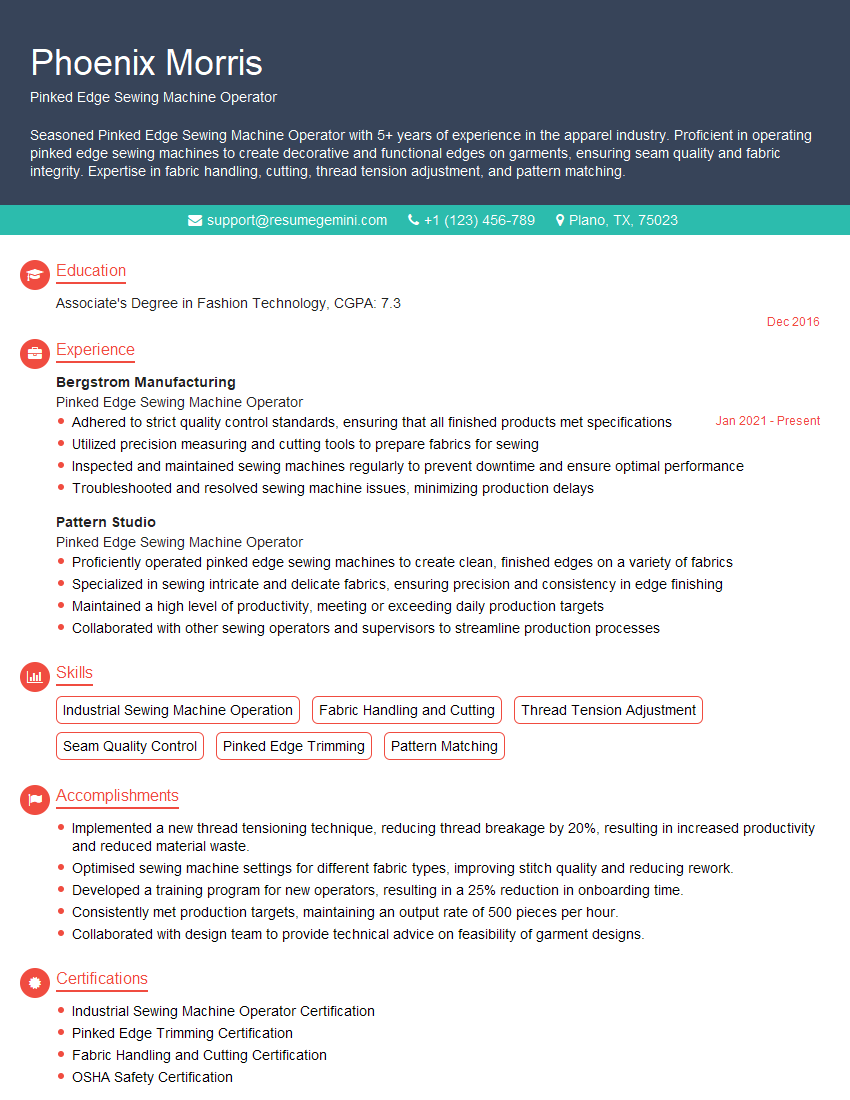

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pinked Edge Sewing Machine Operator

1. Describe the process of pinking fabric edges?

Pinked edge sewing involves cutting decorative zigzag patterns along the fabric’s edge to prevent fraying and create a finished look. The process typically involves the following steps:

- Positioning the fabric under the pinking machine’s foot.

- Adjusting the machine’s settings for desired stitch length and width.

- Guiding the fabric through the machine, ensuring even and precise cutting.

- Inspecting the finished edge for any irregularities or missed stitches.

2. What types of fabrics are best suited for pinking?

Natural Fibers

- Cotton: Durable and breathable, suitable for garments, home textiles, and accessories.

- Linen: Strong and wrinkle-resistant, commonly used in clothing, bedding, and tablecloths.

- Silk: Delicate and luxurious, suitable for high-end garments, scarves, and home décor.

Synthetic Fibers

- Polyester: Durable and wrinkle-free, often used in sportswear, outdoor fabrics, and upholstery.

- Nylon: Strong and lightweight, suitable for swimwear, activewear, and hosiery.

- Rayon: Soft and absorbent, similar to cotton, commonly used in clothing and home textiles.

3. How do you maintain and troubleshoot a pinking machine?

To maintain and troubleshoot a pinking machine, I follow these steps:

- Regular Cleaning: Remove thread clippings, fabric dust, and oil residue from the machine’s parts.

- Blade Inspection: Check the pinking blades for sharpness and replace them if dull or damaged.

- Tension Adjustment: Ensure proper tension on the upper and lower threads for optimal stitch quality.

- Lubrication: Apply lubricant to moving parts according to the manufacturer’s recommendations.

- Troubleshooting: If the machine is not cutting evenly or producing skipped stitches, check for thread tangles, blade alignment, and proper tension.

4. What safety precautions should be taken when operating a pinking machine?

To ensure safety while operating a pinking machine, I adhere to the following precautions:

- Wear Safety Gear: Use safety glasses and gloves to protect from flying debris and sharp blades.

- Secure Loose Clothing: Tie back long hair and avoid loose clothing that could get caught in the machine.

- Inspect Machine: Check the machine thoroughly before each use for any damage or loose parts.

- Proper Threading: Follow the manufacturer’s instructions for threading the machine correctly.

- Caution Around Blades: Avoid touching the sharp pinking blades directly and handle them with care.

5. How do you adjust the stitch length and width on a pinking machine?

Adjusting stitch length and width on a pinking machine involves the following steps:

- Locate the stitch length and width dials or knobs on the machine.

- Turn the stitch length dial to adjust the distance between stitches, typically measured in millimeters.

- Turn the stitch width dial to adjust the width of the zigzag stitch, affecting the amount of fabric removed.

- Experiment with different settings to achieve the desired stitch appearance for the specific fabric and application.

6. What is the difference between a 2-knife and a 3-knife pinking machine?

2-Knife Pinker

- Produces a basic zigzag stitch with two blades.

- Suitable for light to medium-weight fabrics.

- Creates a more subtle decorative edge.

3-Knife Pinker

- Produces a more intricate zigzag stitch with three blades.

- Capable of handling heavier fabrics and creating a stronger, more finished edge.

- Results in a more pronounced decorative effect.

7. How do you handle different types of fabric thicknesses and textures when pinking?

To handle different fabric thicknesses and textures when pinking, I make the following adjustments:

- Thin Fabrics: Use a shorter stitch length and narrower stitch width to prevent puckering or tearing.

- Thick Fabrics: Use a longer stitch length and wider stitch width to ensure proper penetration and edge finishing.

- Delicate Fabrics: Use a light touch and reduce pressure on the fabric to avoid damaging the fibers.

- Textured Fabrics: Adjust the tension settings and stitch length to accommodate the uneven surface.

8. How do you ensure consistent and precise pinking operations?

To ensure consistent and precise pinking operations, I follow these practices:

- Proper Threading: Ensure the machine is correctly threaded to prevent tension issues and skipped stitches.

- Sharp Blades: Regularly check and replace dull or damaged pinking blades to maintain optimal cutting performance.

- Fabric Preparation: Iron the fabric to remove wrinkles and ensure a smooth cutting surface.

- Steady Guiding: Guide the fabric evenly through the machine to avoid uneven edges or missed stitches.

- Quality Control: Regularly inspect the finished edges for any imperfections and make adjustments as needed.

9. What are some common problems that can occur when using a pinking machine and how do you resolve them?

Problem: Skipped Stitches

- Cause: Improper threading, dull blades, or incorrect tension.

- Resolution: Check threading, replace blades if necessary, and adjust tension settings.

Problem: Uneven or Ragged Edges

- Cause: Dull blades, incorrect stitch settings, or guiding issues.

- Resolution: Replace blades, adjust stitch length and width, and ensure steady fabric guiding.

Problem: Fabric Puckering

- Cause: Incorrect stitch length or tension settings.

- Resolution: Increase stitch length or loosen tension to reduce pressure on the fabric.

10. Describe a situation where you had to troubleshoot and resolve a complex issue with a pinking machine.

In a previous role, I encountered a situation where the pinking machine was producing uneven and frayed edges despite regular maintenance. After troubleshooting, I noticed a misalignment between the pinking blades. I carefully adjusted the blade alignment according to the manufacturer’s instructions, ensuring they met precisely. This resolved the issue, resulting in clean and consistent pinked edges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pinked Edge Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pinked Edge Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pinked Edge Sewing Machine Operators are responsible for operating specialized sewing machines that create a decorative zigzag stitch along the edges of fabrics. Their key responsibilities include:

1. Fabric Preparation and Loading

Preparing fabrics by inspecting, measuring, and cutting them to the desired size and shape

- Loading fabrics onto the sewing machine and adjusting the tension and stitch settings

2. Sewing Operation

Operating the pinked edge sewing machine to create decorative edges on fabrics

- Maintaining the machine and ensuring its proper functioning

3. Quality Control

Inspecting the finished products for defects and ensuring they meet quality standards

- Making adjustments to the machine or sewing techniques as needed to improve the quality of the stitches

4. Production Management

Keeping track of production quantities and ensuring that deadlines are met

- Working with other team members to ensure smooth production processes

Interview Tips

Preparing for an interview for a Pinked Edge Sewing Machine Operator position requires thorough research, practice, and a confident demeanor. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Visit the company’s website, read about their history, mission, and products. This will demonstrate your interest in the company and help you tailor your answers during the interview

- Familiarize yourself with the job description and identify the key skills and responsibilities required for the role

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating pinked edge sewing machines and your ability to produce high-quality stitches consistently

- Provide specific examples of projects where you successfully used a pinked edge sewing machine

3. Showcase Attention to Detail and Quality Control

Demonstrate your meticulous nature by explaining your quality control procedures and how you ensure the accuracy and precision of your work

- Provide examples of how you identify and correct defects in fabrics or stitches

4. Emphasize Efficiency and Teamwork

Highlight your ability to work efficiently and meet deadlines without compromising quality

- Share your experience working in a team environment and how you contribute to the overall production process

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pinked Edge Sewing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.