Feeling lost in a sea of interview questions? Landed that dream interview for Pipe and Tank Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pipe and Tank Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

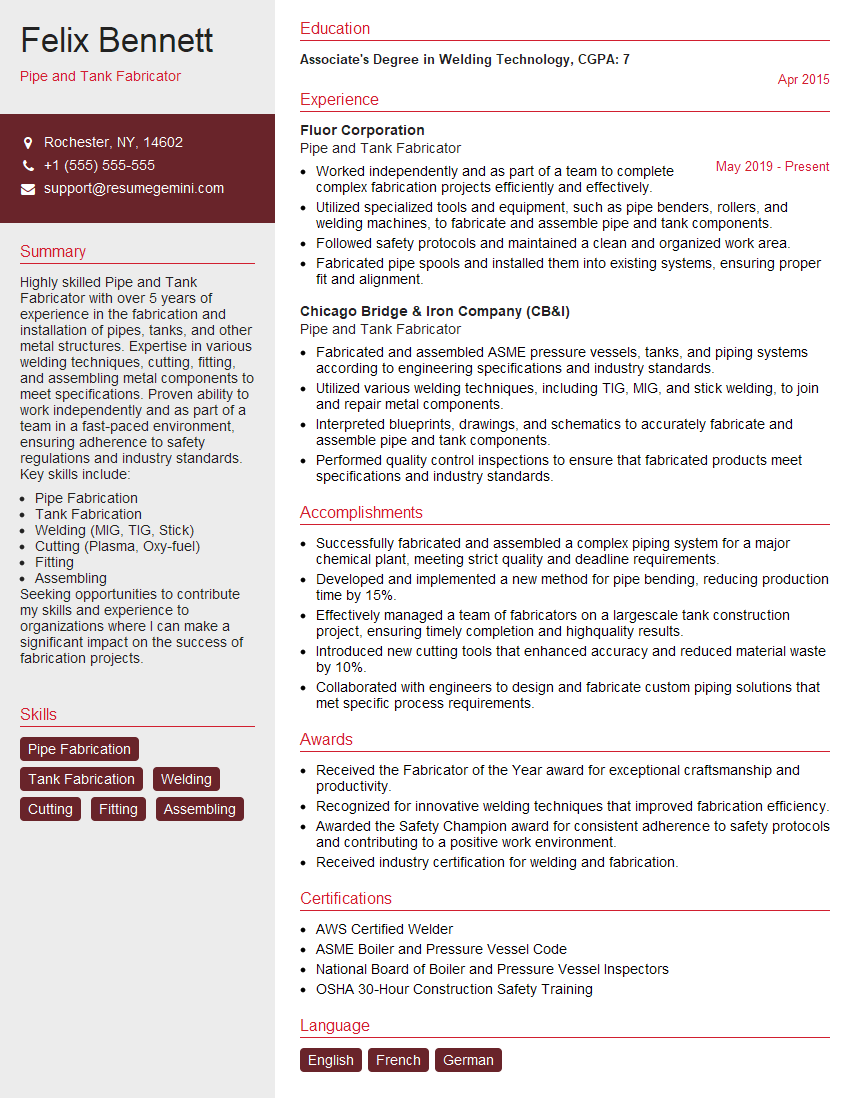

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe and Tank Fabricator

1. What are the different types of welding processes that you are familiar with, and which ones have you used in your previous roles?

In my previous roles, I have used various welding processes, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

I am also familiar with other welding processes, such as oxy-acetylene welding and submerged arc welding, but I have not had the opportunity to use them in a professional setting.

2. How do you ensure the quality of your welds?

Visual Inspection

- Inspecting welds for any defects, such as cracks, porosity, or undercut

Non-Destructive Testing

- Using methods such as radiography, ultrasonic testing, or magnetic particle inspection to identify internal defects

Destructive Testing

- Performing tests such as tensile testing, bend testing, or impact testing to determine the strength and integrity of welds

3. What are the different types of pipe and tank materials that you have worked with?

I have experience working with a variety of pipe and tank materials, including:

- Carbon steel

- Stainless steel

- Aluminum

- Copper

- PVC

- Polyethylene

I am familiar with the properties of each material and how to weld them properly.

4. What are the different types of pipe and tank fittings that you have fabricated?

I have fabricated a variety of pipe and tank fittings, including:

- Elbows

- Tees

- Reducers

- Caps

- Flanges

- Nozzles

I have also fabricated more complex fittings, such as headers, manifolds, and heat exchangers.

5. What are the different types of welding equipment that you are familiar with?

I am familiar with a variety of welding equipment, including:

- Welding machines (SMAW, GMAW, GTAW, FCAW)

- Plasma cutters

- oxy-acetylene torches

- Welding positioners

- Welding fume extractors

I am also familiar with the safety precautions that must be taken when operating welding equipment.

6. What are the different codes and standards that you are familiar with?

I am familiar with a variety of codes and standards, including:

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- American Welding Society (AWS) D1.1 Structural Welding Code

- American Petroleum Institute (API) 1104 Welding of Pipelines and Related Facilities

- National Fire Protection Association (NFPA) 51B Standard for Fire Prevention During Welding, Cutting, and Other Hot Work

I am also familiar with the quality control procedures that must be followed when welding to these codes and standards.

7. What are the different types of welding defects that you have encountered?

I have encountered a variety of welding defects, including:

- Cracks

- Porosity

- Undercut

- Cold lap

- Slag inclusions

- Distortion

I know how to identify these defects and how to prevent them from occurring.

8. What are the different types of welding repairs that you have performed?

I have performed a variety of welding repairs, including:

- Repairing cracks

- Filling porosity

- Removing undercut

- Correcting distortion

- Replacing damaged pipe or tank sections

I know how to properly prepare the weld area and select the correct welding process and materials for the repair.

9. What is your experience with working in a team environment?

I have extensive experience working in a team environment. In my previous roles, I have worked with other pipe and tank fabricators, welders, fitters, and engineers to complete projects on time and within budget.

- Communicating effectively with team members

- Coordinating tasks and responsibilities

- Resolving conflicts and issues

- Supporting and mentoring other team members

I am a team player and I am always willing to lend a helping hand to my colleagues.

10. What are your career goals?

My career goal is to become a highly skilled and experienced pipe and tank fabricator. I want to continue to develop my skills and knowledge in the field, and I am eager to take on new challenges and responsibilities.

I am also interested in pursuing a leadership role in the future. I believe that my experience and skills would make me a valuable asset to any team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe and Tank Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe and Tank Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe and Tank Fabricators play a vital role in various industries, specializing in the fabrication of pipes and tanks used in the construction and maintenance of pipelines, storage facilities, and process equipment. Their job responsibilities encompass a wide range of tasks, including:

1. Fabrication and Assembly

Fabricators are responsible for cutting, forming, and joining metal components to create pipes and tanks according to specified designs and dimensions. This involves using specialized tools and equipment, such as welding machines, grinders, and bending machines, to produce high-quality, precise fabrications.

- Interpret blueprints and technical drawings to determine fabrication requirements

- Select and cut appropriate materials, including steel, aluminum, and stainless steel

- Form and shape metal components using bending, rolling, and welding techniques

- Assemble and weld components to create pipes, tanks, and other structures

- Ensure that welds meet industry standards and specifications

2. Installation and Repair

Fabricators are also involved in the installation and repair of pipes and tanks on-site. They work closely with plumbers and other tradespeople to ensure proper installation and maintenance of pipelines and storage systems.

- Install and connect pipes, tanks, and other components

- Troubleshoot and repair leaks, cracks, and other issues

- Maintain and inspect pipelines and storage systems to ensure safety and efficiency

- Perform routine maintenance and cleaning to prevent corrosion and extend the lifespan of equipment

3. Quality Control and Inspection

Fabricators are responsible for ensuring the quality of their work throughout the fabrication process. They conduct inspections and tests to verify that pipes and tanks meet the required standards and specifications.

- Inspect welds and joints for defects and imperfections

- Test pipes and tanks for pressure and leakage

- Document and record inspection results

- Adhere to safety regulations and industry best practices

4. Material Handling and Storage

Fabricators work with heavy materials and equipment, so proper material handling and storage are essential. They are responsible for loading, unloading, and storing materials safely and efficiently to prevent damage or injury.

- Handle and move heavy materials, such as steel plates and pipes

- Store materials in designated areas to ensure proper inventory and organization

- Maintain a clean and organized work environment

- Follow safety protocols for material handling and storage

Interview Tips

Preparation is key to acing any job interview, and the interview for a Pipe and Tank Fabricator position is no exception. Here are some tips to help you prepare and increase your chances of success:

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will give you a better understanding of the company’s values, goals, and the responsibilities of the role. You can find this information on the company’s website, LinkedIn page, or through industry publications.

2. Practice Answering Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver clear, concise, and well-thought-out responses.

3. Highlight Your Relevant Skills and Experience

In your resume and during the interview, be sure to highlight your relevant skills and experience that align with the job requirements. For example, if you have experience in welding, pipefitting, or fabrication, make sure to mention this. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

4. Be Prepared to Talk About Your Safety Knowledge

Safety is paramount in the fabrication industry, so be prepared to talk about your knowledge of safety protocols and regulations. This could include topics such as proper use of tools and equipment, hazardous materials handling, and emergency procedures.

5. Show Your Enthusiasm and Eagerness to Learn

Employers are looking for candidates who are enthusiastic about the field of fabrication and eager to learn new skills. During the interview, be sure to express your passion for the work and your willingness to take on new challenges.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pipe and Tank Fabricator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.