Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pipe Caulker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

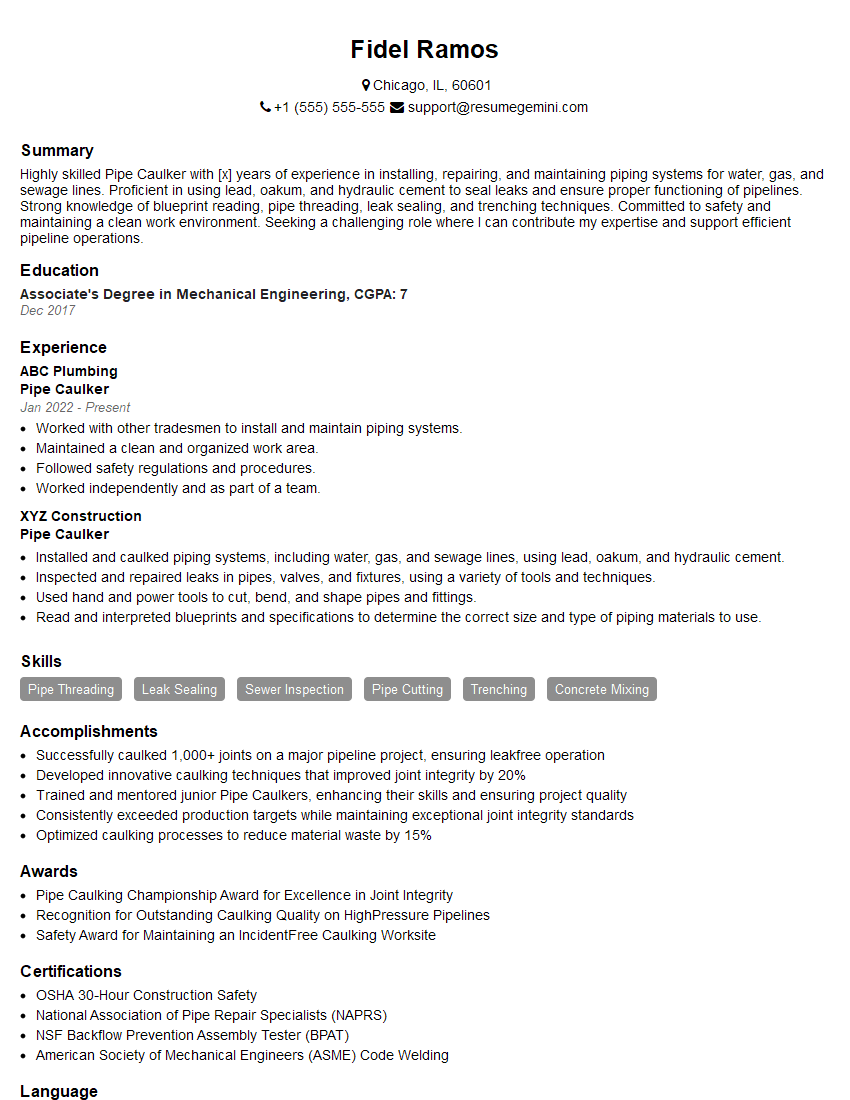

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Caulker

1. What are the different types of pipe caulking materials and their applications?

There are various types of pipe caulking materials, each with its specific applications:

- Polyurethane Caulk: High-performance sealant for filling gaps, sealing joints, and preventing leaks in plumbing and HVAC systems.

- Silicone Caulk: Flexible and waterproof sealant for sealing joints around sinks, tubs, showers, and other fixtures.

- Acrylic Caulk: Paintable and easy-to-apply sealant for sealing gaps and cracks in walls, ceilings, and around windows and doors.

- Butyl Rubber Caulk: Adhesive sealant for sealing joints in roofing, flashing, and other outdoor applications.

- Polysulfide Caulk: High-strength sealant for sealing joints in chemical processing equipment, tanks, and pipes.

2. What are the key steps involved in preparing a pipe surface for caulking?

Surface Preparation:

- Clean the pipe surface thoroughly to remove dirt, grease, and debris.

- Use a wire brush or sandpaper to roughen the surface slightly, creating a better bond for the caulk.

- Mask off adjacent areas to protect them from overspray or spills.

Priming (if necessary):

- Apply a primer to non-porous surfaces, such as metal or PVC pipes, to enhance the adhesion of the caulk.

3. What are the proper techniques for applying caulk to a pipe joint?

To achieve a professional and effective seal:

- Caulk Gun Pressure: Adjust the caulk gun to the appropriate pressure recommended for the specific caulk being used.

- Caulk Bead Placement: Apply the caulk bead in a steady, even motion, following the contour of the pipe joint.

- Caulk Bead Size: The bead size should be sufficient to fill the joint without creating excess that can sag or tear.

- Smoothing and Finishing: Use a caulk tool or your finger to smooth the caulk bead and ensure it is properly seated in the joint.

4. What are the safety precautions to consider when working with pipe caulking materials?

- Ventilation: Ensure adequate ventilation to avoid inhaling fumes.

- Skin Protection: Wear gloves to prevent skin contact with caulk materials.

- Eye Protection: Wear safety glasses to protect eyes from splashes or fumes.

- Proper Storage: Store caulk materials in accordance with manufacturer’s instructions to maintain their integrity and effectiveness.

5. How do you troubleshoot and repair leaks in pipe joints that have been caulked?

- Identify the Source: Inspect the joint for any visible cracks or gaps where the caulk may have failed.

- Remove Old Caulk: Use a utility knife or caulk removal tool to carefully scrape away the old, damaged caulk.

- Clean and Prepare: Clean the joint surface and prepare it for recaulking as described in question 2.

- Apply New Caulk: Apply a new bead of caulk using proper techniques and allow it to cure fully.

- Test and Monitor: Once cured, test the joint for leaks and monitor it over time to ensure the repair is effective.

6. What are the best practices for maintaining caulked pipe joints to prevent future leaks?

- Regular Inspection: Periodically inspect caulked joints for any signs of damage, cracking, or shrinkage.

- Cleanliness: Keep caulked joints clean by wiping away dirt, grease, or debris that can weaken the seal over time.

- Re-caulking: If a caulked joint shows signs of wear or failure, promptly remove the old caulk and re-caulk the joint to prevent leaks.

7. What are the advantages of using caulk to seal pipe joints compared to other methods?

- Flexibility and Adaptability: Caulk is flexible and can conform to the shape of the joint, making it suitable for various pipe configurations.

- Waterproof and Leak Prevention: Properly applied caulk creates a waterproof seal that prevents leaks and protects against moisture damage.

- Cost-Effectiveness: Caulk is an affordable and cost-effective solution for sealing pipe joints, compared to more complex or expensive methods.

- Ease of Application: Caulking is a relatively easy process that can be performed by DIY enthusiasts or professionals without extensive training.

8. What are some common mistakes to avoid when caulking pipe joints?

- Applying Caulk Over Dirty or Wet Surfaces: Ensure the joint is clean and dry before applying caulk.

- Using the Wrong Type of Caulk: Choose the appropriate caulk type based on the specific application and material properties.

- Over-applying Caulk: Apply a bead of caulk that is sufficient to fill the joint without creating excess that can sag or tear.

- Not Smoothing the Caulk: Use a caulk tool or your finger to smooth the caulk bead for a professional finish and to ensure proper adhesion.

9. What are some innovative techniques or tools used in pipe caulking?

- Caulk Guns with Variable Pressure: These guns allow precise control over the amount of caulk dispensed, ensuring a consistent and effective application.

- Caulk Finishing Tools: Specialized tools are available to help smooth and shape the caulk bead for a professional-looking finish.

- Self-Leveling Caulk: Certain types of caulk are designed to self-level, creating a smooth and even surface without additional finishing.

10. What are the environmental considerations when disposing of pipe caulking materials?

- Proper Disposal: Dispose of uncured caulk and empty caulk tubes in accordance with local regulations and guidelines.

- Cured Caulk: Cured caulk can be considered non-hazardous and disposed of as solid waste.

- Environmental Impact: Choose caulk materials that are environmentally friendly and have low VOC (Volatile Organic Compound) emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Caulker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Caulker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Caulkers are responsible for installing and maintaining underground pipes, such as water and sewer lines, by caulking joints between pipes and other components to prevent leaks and ensure the system’s integrity.

1. Pipe Caulk Installation and Caulking

Installs and caulk pipes according to specifications and blueprints, using appropriate tools and materials.

- Reads blueprints and drawings to determine the type and size of pipe to be installed.

- Cuts, threads, and assembles pipes.

- Applies caulking to joints and connections to prevent leaks.

2. Maintenance and Repair

Identifies and repairs leaks in pipes and other components of the piping system. Inspects and tests pipes for leaks and other issues.

- Troubleshoots leaks and other issues in the piping system.

- Repairs or replaces damaged pipes.

- Tightens bolts and connections to prevent leaks.

3. Safety and Compliance

Follows safety protocols and regulations to ensure a safe work environment.

- Wears appropriate personal protective equipment (PPE).

- Follows established safety procedures.

- Complies with industry standards and regulations.

4. Communication and Teamwork

Communicates effectively with colleagues and supervisors to coordinate work and resolve issues.

- Works as part of a team to install and maintain piping systems.

- Communicates with supervisors and other tradespeople to ensure coordination of work.

- Provides updates on project progress and any issues or concerns.

Interview Tips

To ace the interview for a Pipe Caulker position, it is crucial to prepare and showcase your skills and experience.

1. Research the Company and Position

Research the company’s history, values, and the specific requirements of the Pipe Caulker position. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Prepare questions to ask the interviewer about the company and the position.

2. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience in pipe caulking and maintenance. Quantify your accomplishments whenever possible.

- Describe specific projects where you installed, maintained, or repaired piping systems.

- Highlight your expertise in using various caulking materials and techniques.

- Showcase your knowledge of safety protocols and industry standards.

3. Demonstrate Your Commitment to Safety

Emphasize your commitment to safety and compliance. Discuss your experience following safety procedures and using proper PPE.

- Provide examples of how you have identified and resolved safety hazards.

- Explain your understanding of OSHA regulations and industry best practices.

- Express your willingness to undergo additional safety training if required.

4. Showcase Your Teamwork and Communication Skills

Highlight your ability to work effectively as part of a team and communicate clearly with others.

- Describe your experience collaborating with colleagues and clients.

- Provide examples of how you have successfully resolved conflicts or issues.

- Emphasize your commitment to providing updates and maintaining open communication.

5. Practice and Prepare

To improve your confidence and recall during the interview, practice answering common interview questions. Prepare for questions related to your skills, experience, safety, teamwork, and the company.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Ask a friend or family member to conduct a mock interview.

- Prepare questions to ask the interviewer about the company, the position, and the team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pipe Caulker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pipe Caulker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.